Split hoop spacer

A spacer and split-type technology, which is applied in the direction of the device for maintaining the distance between parallel conductors, can solve the problems of easy generation of air holes, trachoma, low production efficiency, scrapping of spacer bars, etc., and achieves improved connection reliability, simple structure, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

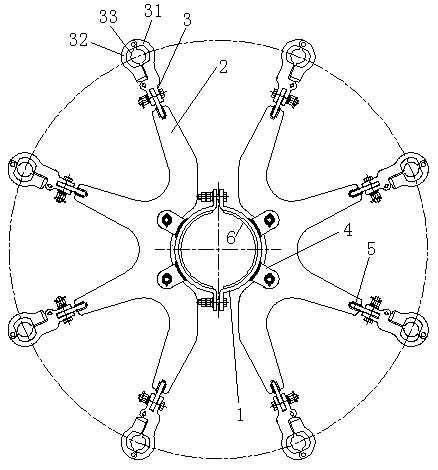

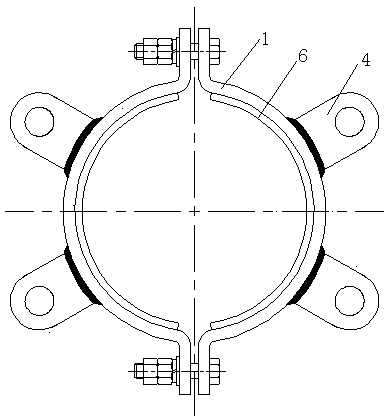

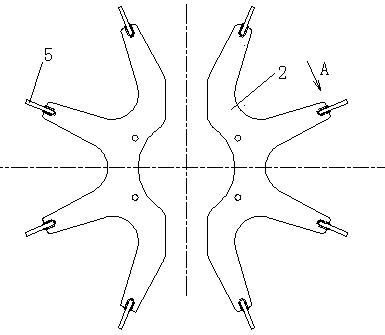

[0018] Reference attached figure 1 , Attached figure 2 , Attached image 3 , Attached Figure 4 , A split type hoop spacer of the present invention is composed of hoop 1, frame plate 2, wire clamp 3, frame plate connecting seat 4, wire clamp connecting plate 5, and non-slip pad 6. The hoop 1 is Two symmetrical semicircular rings are connected by bolts to form a circular ring hoop, and two frame plate connection seats 4 are welded on the semicircular ring; an anti-skid pad 6 is provided on the inner surface of the hoop 1. And the contact surface between the anti-skid pad 6 and the frame is provided with anti-skid patterns; the frame plate 2 is connected with the frame plate connecting seat 4 by bolts; the frame plate 2 is an arc-shaped plate body with a toothed structure; The connecting plate 5 is inserted into the groove of the toothed structure end of the frame plate 2 and welded to form a whole; the wire clamp 3 is arranged on the wire clamp connecting plate 5; the hoop 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com