A rotary nut cracker

A shell breaking machine and rotary technology, which is applied in the field of food processing, can solve the problems of high energy consumption, low crushing efficiency, and large space occupied by equipment installation, so as to achieve the effects of ensuring economic value, saving working time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

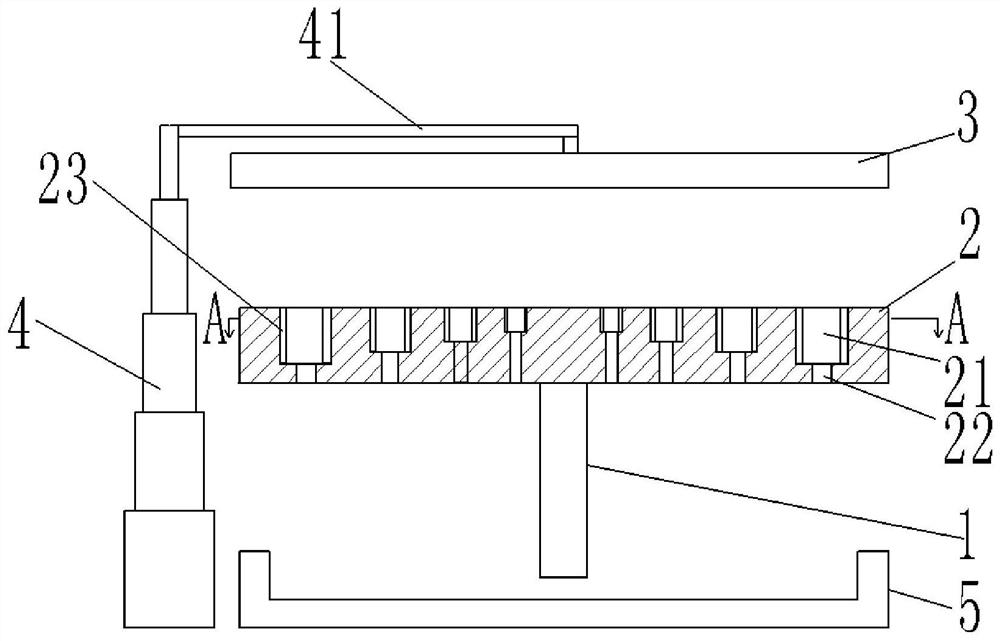

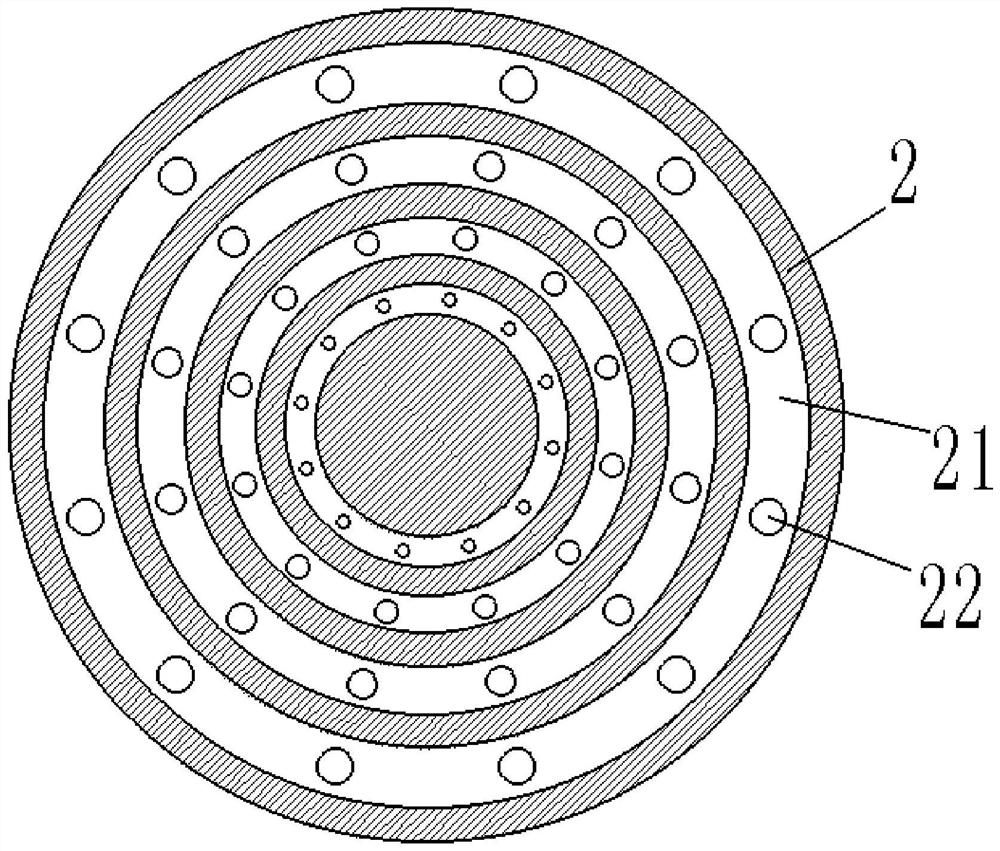

[0022] The reference numerals in the drawings of the description include: supporting device 1 , containing device 2 , annular groove 21 , through hole 22 , air bag 23 , pressure plate 3 , telescopic device 4 , connecting rod 41 , and recovery groove 5 .

[0023] Such as figure 1 A rotary nut cracking machine shown includes a supporting device 1, and the upper end of the supporting device 1 is rotatably equipped with an accommodating device 2. The accommodating device 2 in this embodiment is set as a disc, and the upper surface of the accommodating device 2 is Four annular grooves 21 are provided. The centers of the annular grooves 21 coincide but the radii gradually increase. The width and depth of the annular grooves 21 increase one by one with the increase of the radius of the annular grooves 21 . Airbags 23 are installed on both side walls of the annular groove 21, and the airbags 23 are made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com