Bamboo reed dissolving pulp pretreating method

A technology of dissolving pulp and primary processing, applied in the direction of pulping with organic solvents, pulping of cellulose raw materials, non-woody plant/crop pulp, etc., can solve the problems of not exerting economic value, achieve significant environmental protection effects, and improve Effects of Effective Utilization and Capacity Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (a) Arundos reed is crushed, crushed and cut into sections, with an average length of 3cm;

[0031] (b) washing the reed bamboo sheets, removing mud and dust, and putting them in a pot;

[0032] (c) adding the reed bamboo slices into the hydrolysis solution, soaking them in the solid acid catalyst for 30 minutes, the ratio of the weight of the hydrolysis solution to the weight of the reed bamboo flakes is 1.5:1;

[0033] The weight consumption of solid acid catalyst is 5% of the bamboo tablet;

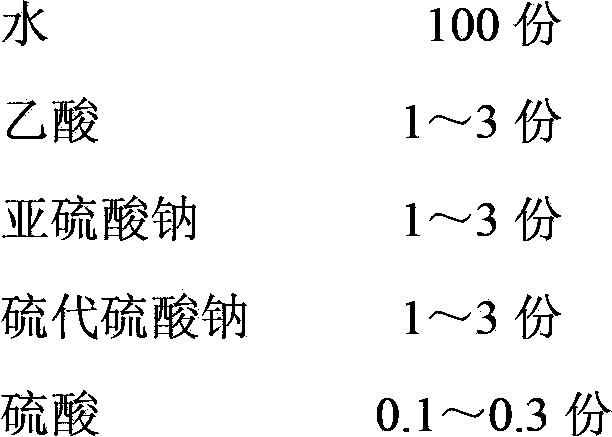

[0034] The parts by weight of the hydrolyzed solution include:

[0035]

[0036] (d) Then cook all the materials in step (3) at 130°C for 30 minutes;

[0037] (e) Heat up to 160°C and keep for 30 minutes;

[0038] (f) Degassing, collecting the cooking slurry and solid acid catalyst separately, and washing the cooking slurry with water at 80-90°C;

[0039] (g) Add sodium hydroxide solution with a weight concentration of 5% to the cooking slurry, soak for 30 minutes, then c...

Embodiment 2

[0046] (a) Arundos reed is crushed, crushed and cut into sections, with an average length of 5cm;

[0047] (b) washing the reed bamboo sheets, removing mud and dust, and putting them in a pot;

[0048] (c) adding the reed bamboo flakes into the hydrolysis solution, soaking them in the solid acid catalyst for 60 minutes, the ratio of the weight of the hydrolysis solution to the weight of the reed bamboo flakes is 2:1;

[0049] The weight consumption of solid acid catalyst is 15% of the bamboo tablet;

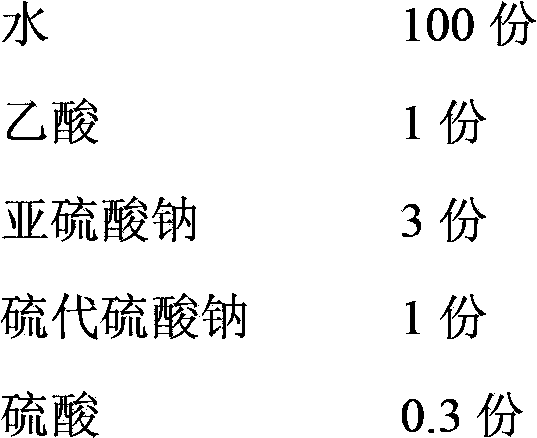

[0050] The parts by weight of the hydrolyzed solution include:

[0051]

[0052] (d) Then cook all the materials in step (3) at 150°C for 60 minutes;

[0053] (e) Heat up to 180°C and keep for 60 minutes;

[0054] (f) Degassing, collecting the cooking slurry and solid acid catalyst separately, and washing the cooking slurry with water at 80-90°C;

[0055] (g) Add sodium hydroxide solution with a weight concentration of 10% to the cooking slurry, soak for 60 minutes, then c...

Embodiment 3

[0062] (a) Arundos reed is crushed, crushed and cut into sections, with an average length of 4cm;

[0063] (b) washing the reed bamboo sheets, removing mud and dust, and putting them in a pot;

[0064](c) adding the reed bamboo flakes into the hydrolysis solution, soaking them in the solid acid catalyst for 50 minutes, the ratio of the weight of the hydrolysis solution to the weight of the reed bamboo flakes is 1.75:1;

[0065] The weight consumption of solid acid catalyst is 10% of the bamboo tablet;

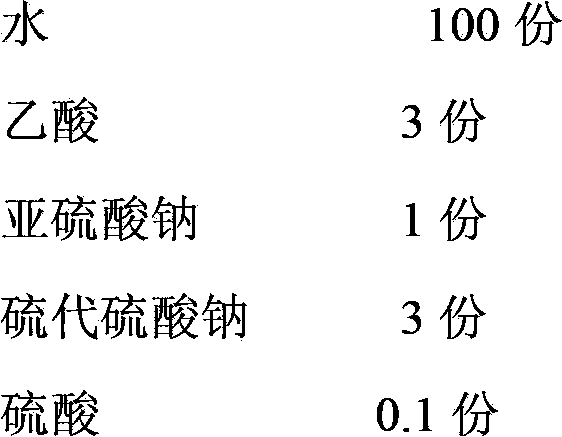

[0066] The parts by weight of the hydrolysis solution include:

[0067]

[0068] (d) Then cook all the materials in step (3) at 140°C for 45 minutes;

[0069] (e) Heat up to 170°C and keep for 50 minutes;

[0070] (f) Deflate and reduce pressure, collect the cooking slurry and solid acid catalyst separately, and wash the cooking slurry with water at 80-90°C;

[0071] (g) Add sodium hydroxide solution with a weight concentration of 8% to the cooking slurry, soak for 45 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com