High-efficiency waste oil drum treatment system

A treatment system and waste oil technology, which is applied in the field of high-efficiency treatment systems, can solve problems such as low treatment efficiency and poor treatment effect, and achieve the effects of improving treatment efficiency, reducing labor intensity, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

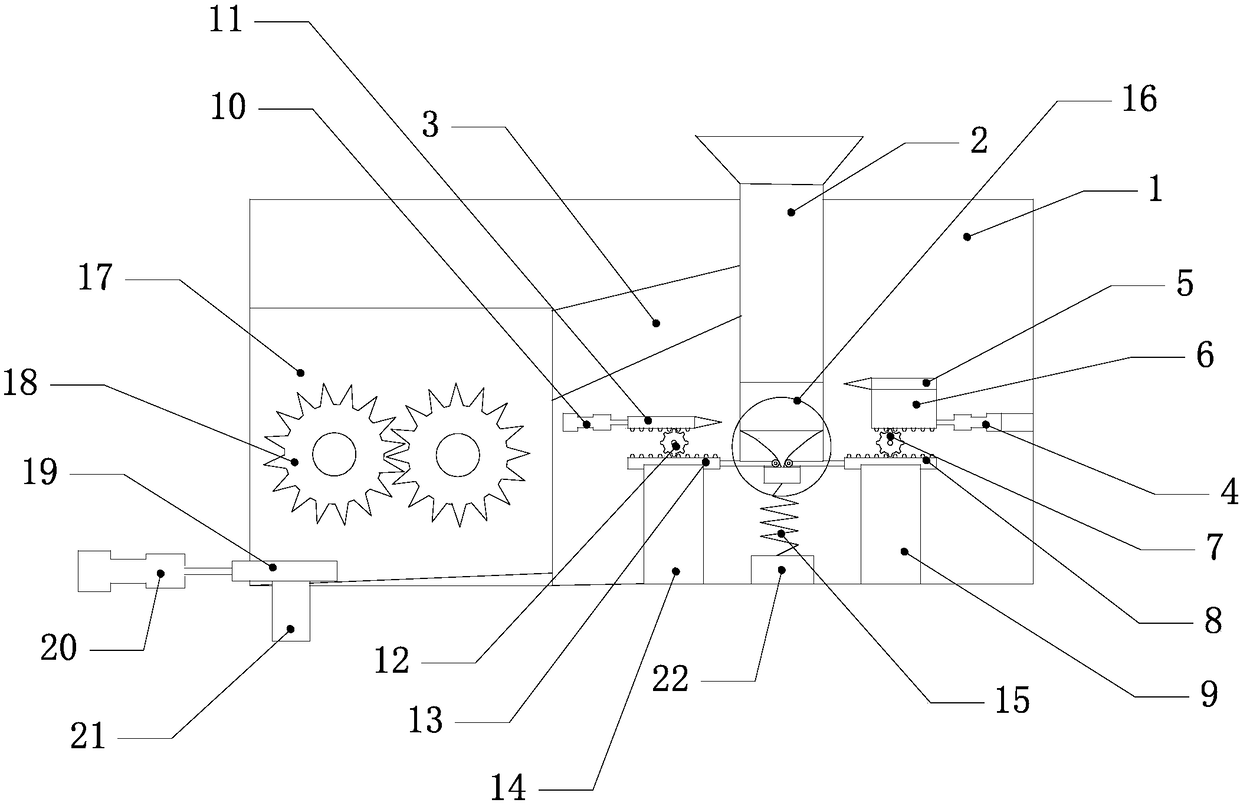

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] The reference signs in the accompanying drawings of the specification include:

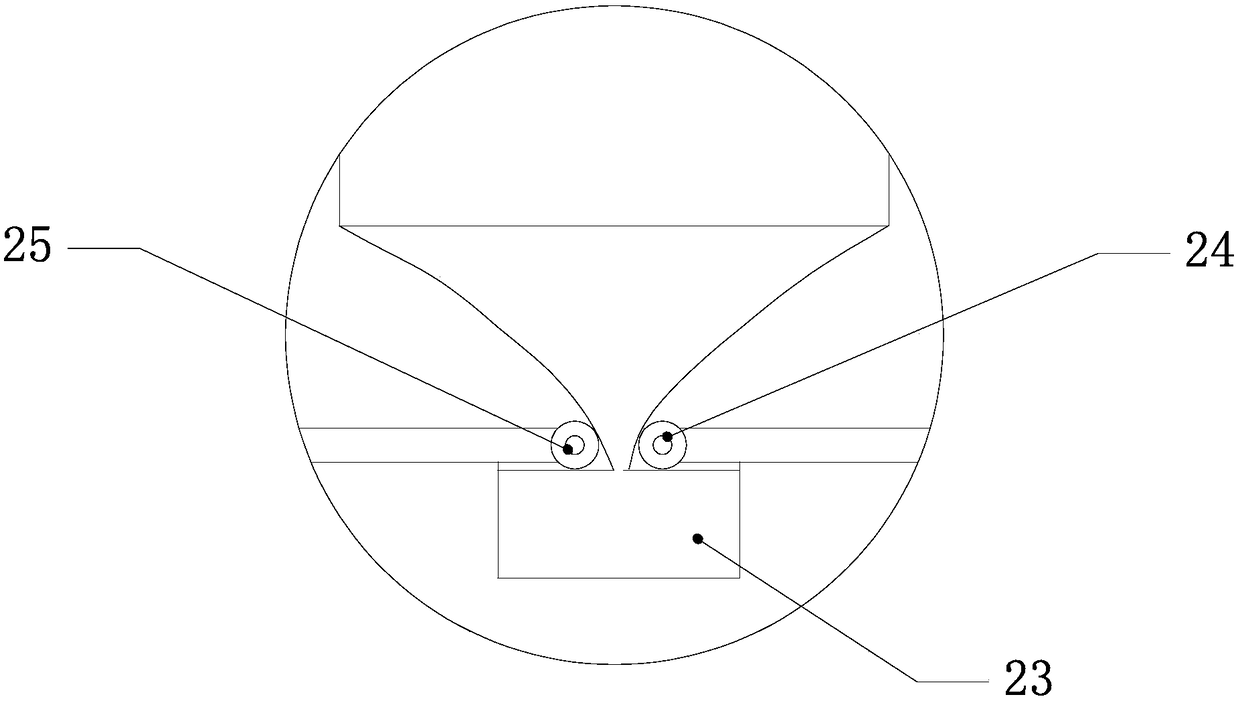

[0023] Frame 1, cutting cylinder 2, discharge pipe 3, first cylinder 4, first cutting knife 5, boss 6, first gear 7, first rack 8, first support column 9, second cylinder 10, The second cutting knife 11, the second gear 12, the second rack 13, the second support column 14, the return spring 15, the lifting block 16, the crushing box 17, the roller gear 18, the oil collection box 19, the third cylinder 20, A discharge conduit 21 , a first support plate 22 , a second support plate 23 , a first roller 24 , and a second roller 25 .

[0024] like Figure 1~2 The shown high-efficiency treatment system for waste oil barrels includes a frame 1, a cutting cylinder 2 and a crushing box 17 arranged on the frame 1, and a discharge port is provided on the side wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap