Lifting type on-site regeneration device for SCR (Selective Catalytic Reduction) catalyst

An SCR catalyst, lift-type technology, applied in the field of flue gas purification, can solve the problems of SCR denitrification catalyst module damage, thin catalyst wall, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

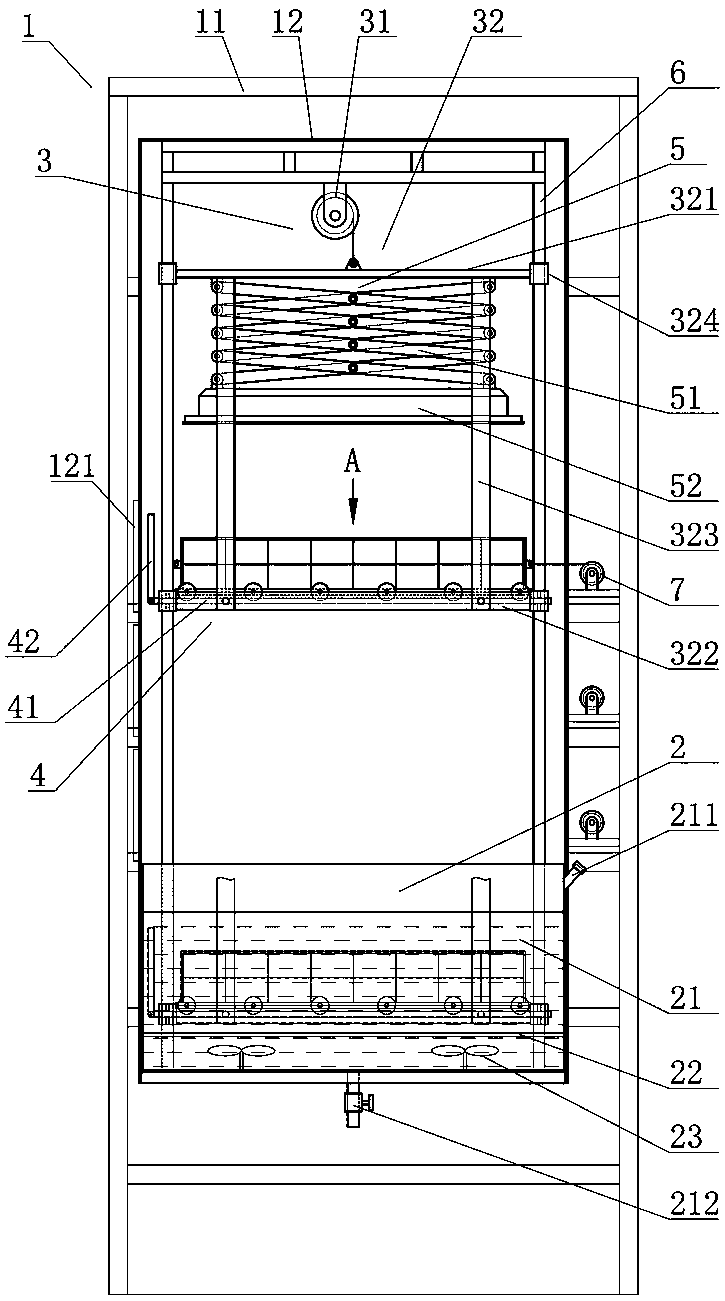

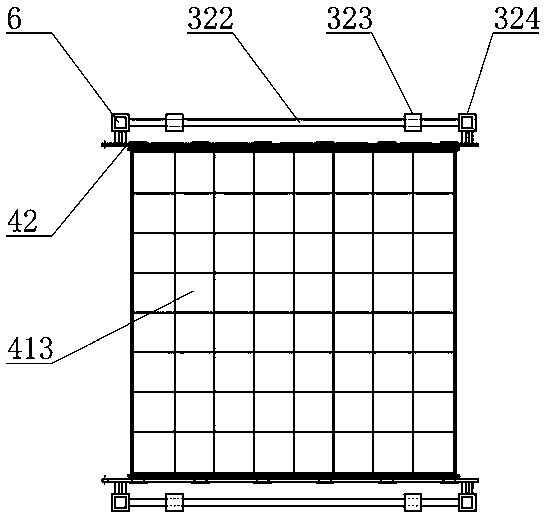

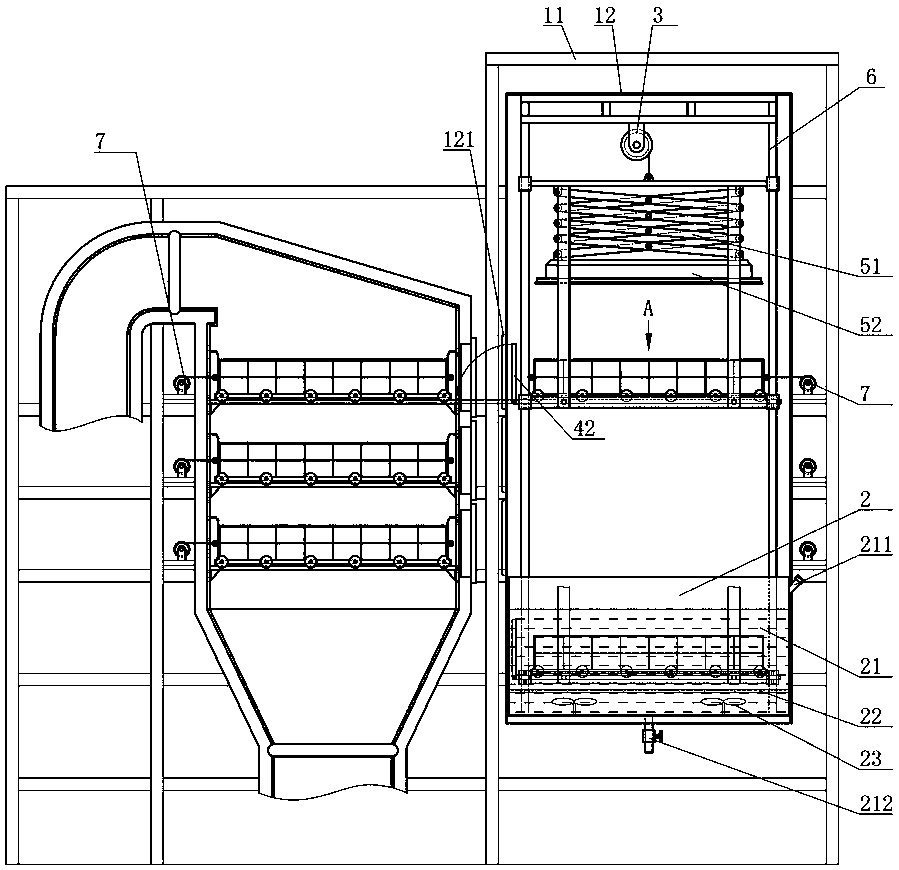

[0027] Figure 1 to Figure 4 It shows an embodiment of the lifting type SCR catalyst on-site regeneration equipment of the present invention, including a fixed support frame 1 docked with the SCR catalyst on-site reaction station, a liquid storage assembly 2 is provided at the bottom of the fixed support frame 1, and a fixed support frame 1 There is a conveying lifting assembly 3 that can extend into the liquid storage assembly 2. The bottom end of the conveying lifting assembly 3 is provided with a butt joint assembly 4 for connecting the SCR catalyst of the reaction station. There is a heating lift assembly 5 for heating the SCR catalyst. When in use, fill the liquid storage assembly 2 with clear water, move the SCR catalyst in the reaction station to the flat joint assembly 4 in the fixed support frame 1, start the conveying lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com