Acid-base resistant composite material as well as preparation method and application thereof

A composite material, anti-acid and alkali technology, applied in the direction of transportation and packaging, tire parts, special tires, etc., can solve the problems of poor corrosion resistance, low service life, acid resistance, poor aging resistance, etc., to achieve low preparation process, Improve service life and benefit production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

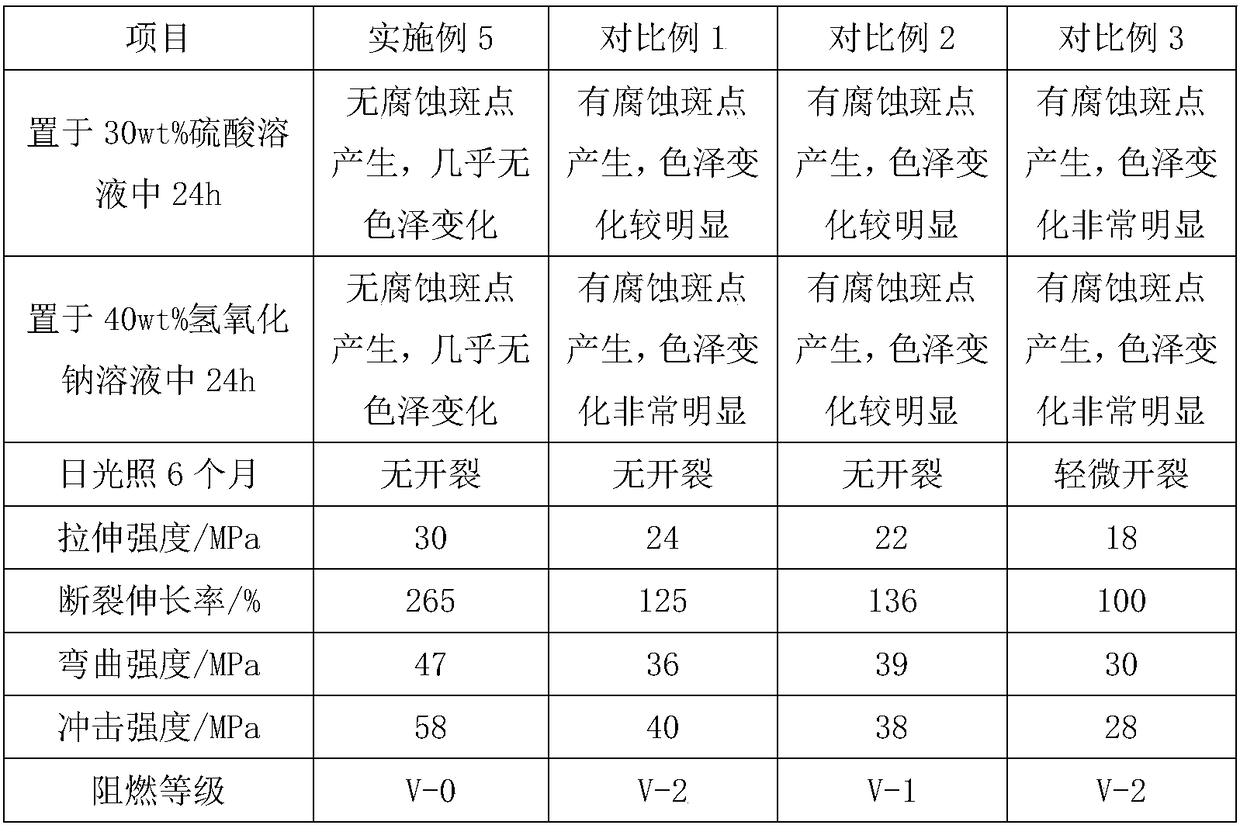

Examples

Embodiment 1

[0015] An acid and alkali resistant composite material, the acid and alkali resistant composite material comprises the following components in parts by weight: 80 parts of rubber, 14 parts of dimethylol dihydroxyethylene urea, 8 parts of octyl diphenyl phosphite, 9 parts of tert-butyl cyclopropanecarboxylate, 6 parts of propiconazole.

[0016] A method for preparing an acid-base resistant composite material, comprising the following steps: (1) mixing octyldiphenyl phosphite, tert-butyl cyclopropanate and propiconazole, stirring at 120°C for 3 hours; The speed is 160r / min; (2) Add dimethylol dihydroxyethylene urea to the result of the previous step, and use dropwise addition, stirring while adding, after the addition, continue to stir and react at 118°C for 1h; stir The speed is 130r / min; (3) Mix the product obtained in the previous step with rubber, mix and stir for 1 hour at 225°C, and the stirring speed is 200r / min;

Embodiment 2

[0018] An acid and alkali resistant composite material, the acid and alkali resistant composite material comprises the following components in parts by weight: 150 parts of rubber, 18 parts of dimethylol dihydroxyethylene urea, 15 parts of octyl diphenyl phosphite, 12 parts of tert-butyl cyclopropanecarboxylate, 9 parts of propiconazole.

[0019] A method for preparing an acid-base resistant composite material, comprising the following steps: (1) mixing octyldiphenyl phosphite, tert-butyl cyclopropanate and propiconazole, stirring at 150°C for 5 hours; stirring The speed is 260r / min; (2) Add dimethylol dihydroxyethylene urea to the result of the previous step, and use the method of dropwise addition, stirring while adding, after the addition, continue to stir and react at 120°C for 2h; stir The speed is 200r / min; (3) Mix the product obtained in the previous step with rubber, mix and stir at 260°C for 2 hours, and the stirring speed is 350r / min;

Embodiment 3

[0021] An acid and alkali resistant composite material, the acid and alkali resistant composite material comprises the following components in parts by weight: 125 parts of rubber, 16 parts of dimethylol dihydroxyethylene urea, 12 parts of octyl diphenyl phosphite, 11 parts of tert-butyl cyclopropanecarboxylate, 8 parts of propiconazole.

[0022] A method for preparing an acid-base resistant composite material, comprising the following steps: (1) mixing octyldiphenyl phosphite, tert-butyl cyclopropanate and propiconazole, stirring at 135°C for 4 hours; stirring The speed is 220r / min; (2) Add dimethylol dihydroxyethylene urea to the result of the previous step, using dropwise addition, stirring while adding, after the addition, continue to stir and react at 119°C for 1.6h; The stirring speed is 170r / min; (3) Mix the product obtained in the previous step with rubber, mix and stir at 240°C for 1.5h, and the stirring speed is 250r / min; then send it into an extruder and extrude it....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com