High-viscoelasticity crack pouring material for acidic aggregate asphalt pavement and preparation method of high-viscoelasticity crack pouring material

A technology for asphalt pavement and joint filling material, which is applied in the direction of asphalt material binder, polymer binder additive, non-polymer binder additive, etc. Problems such as poor scaling performance, to achieve the effect of reducing costs and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

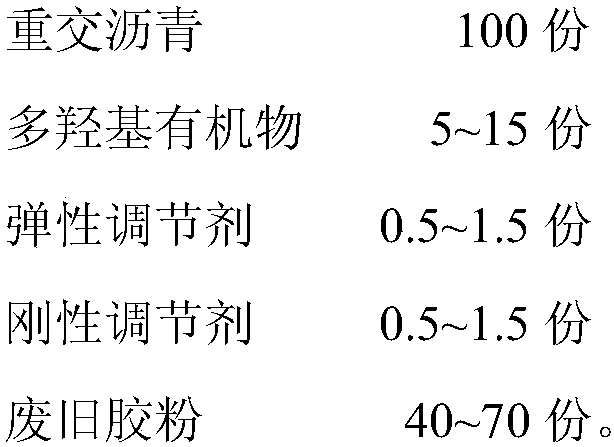

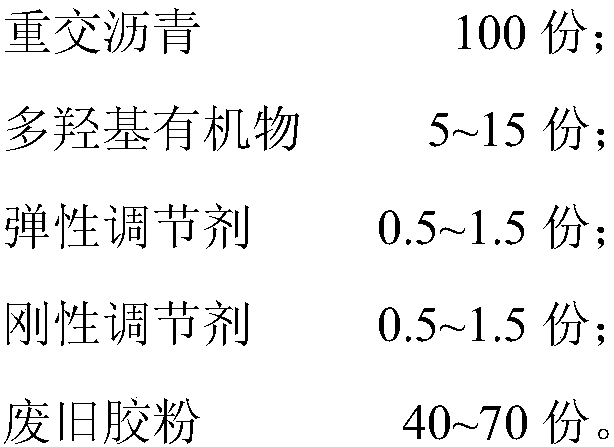

Method used

Image

Examples

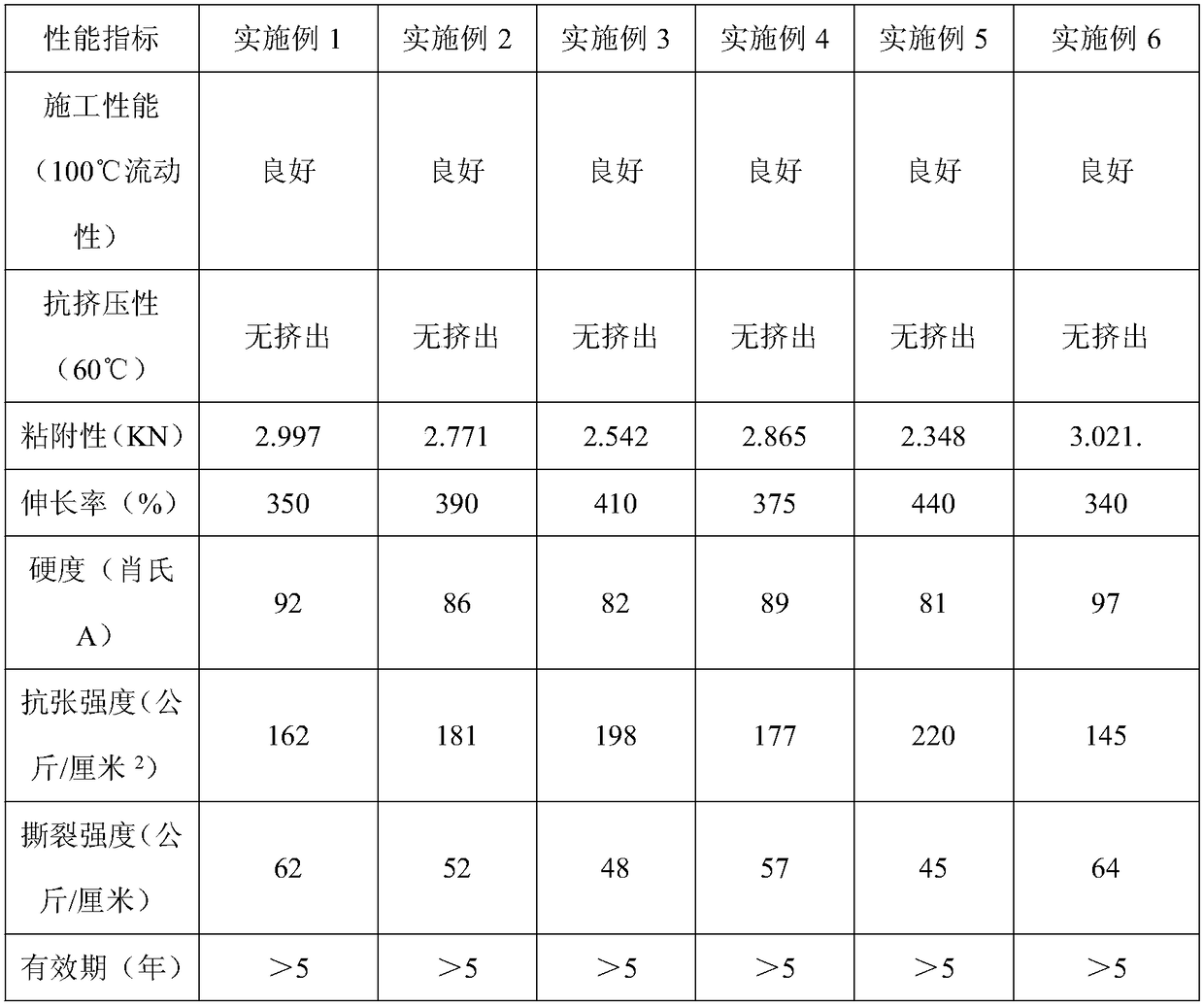

Embodiment 1

[0026] Select 100 parts of heavy traffic road asphalt AH-50 and heat it to a fluid state at 100°C, add 70 parts of waste rubber powder (4 mesh), 5 parts of hydroxyl-terminated polybutadiene rubber compounds (molecular weight 3300 , functionality 2.2), 0.5 parts of elasticity modifier (4,4`-isopropylidene bisphenol) and 0.5 parts of rigidity modifier (1,5-naphthalene diisocyanate); after mixing, stir for 30 minutes and heat up to 145 under the condition of ℃ for 30min; under the condition of lowering the temperature to 100℃ and then stirring for 30min, the preparation is completed.

Embodiment 2

[0028] Select 100 parts of heavy traffic road asphalt AH-50 and heat it to a fluid state at 110°C, add 40 parts of waste rubber powder (4 mesh), 15 parts of hydroxyl-terminated polybutadiene rubber compounds (molecular weight 4400 , functionality 2.2) and 1.5 parts of elasticity modifier (1,4-butanediol) and 0.5 parts of rigidity modifier (1,4-cyclohexyl diisocyanate); after mixing, stir for 25 minutes and heat up to 145°C Shearing for 25 minutes; cooling down to 100°C and stirring for another 30 minutes to complete the preparation.

Embodiment 3

[0030] 100 parts of heavy traffic road asphalt AH-70 was selected and heated to a fluid state at 100°C, and 50 parts of waste rubber powder (8 mesh), 10 parts of hydroxyl-terminated polybutadiene rubber compounds (molecular weight 3600 , functionality 2.4) and 0.5 parts of elasticity modifier (1,4-butanediol) and 1.0 parts of rigidity modifier (1,4-cyclohexyl diisocyanate); after mixing, stir for 20 minutes and heat up to 145°C Shear for 20 minutes; cool down to 100°C and stir for another 30 minutes to complete the preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com