Arsenic purifying and rectifying device and method for purifying arsenic through same

A rectification and rectification tower technology, which is applied in the field of arsenic purification and rectification devices, can solve the problems that the theoretical design cannot realize industrial application, the quartz device has many restrictions, and it is difficult to mention 4 9s of arsenic, etc., and achieves a beneficial purification effect. Efficiency, overcoming preparation brittleness, reducing the effect of blocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

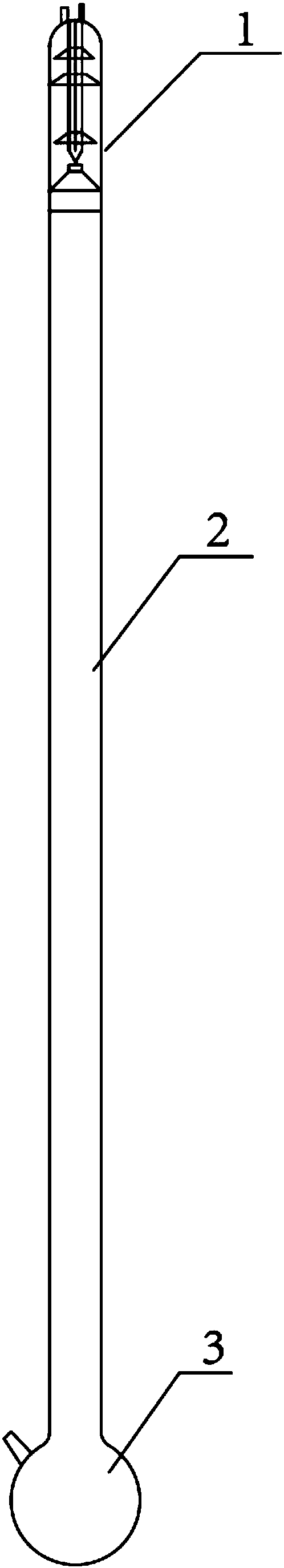

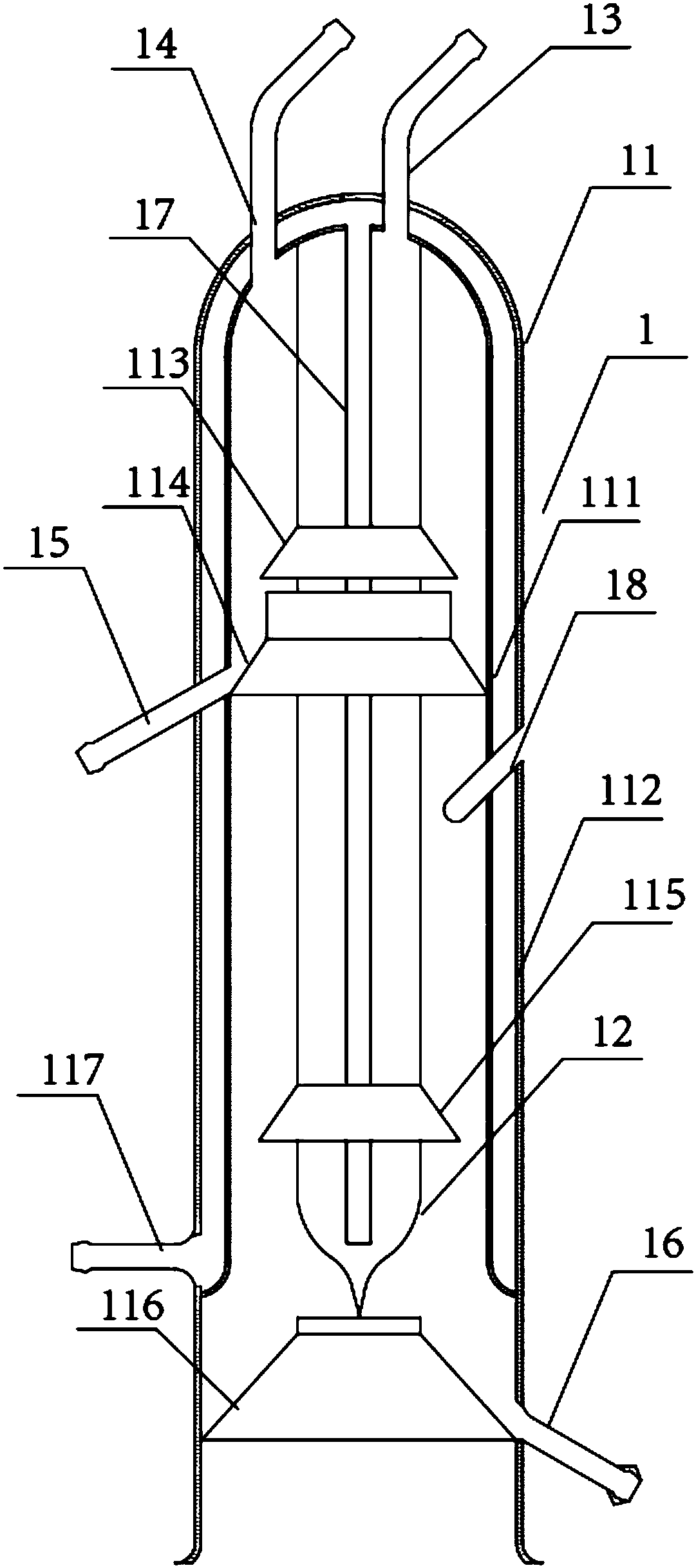

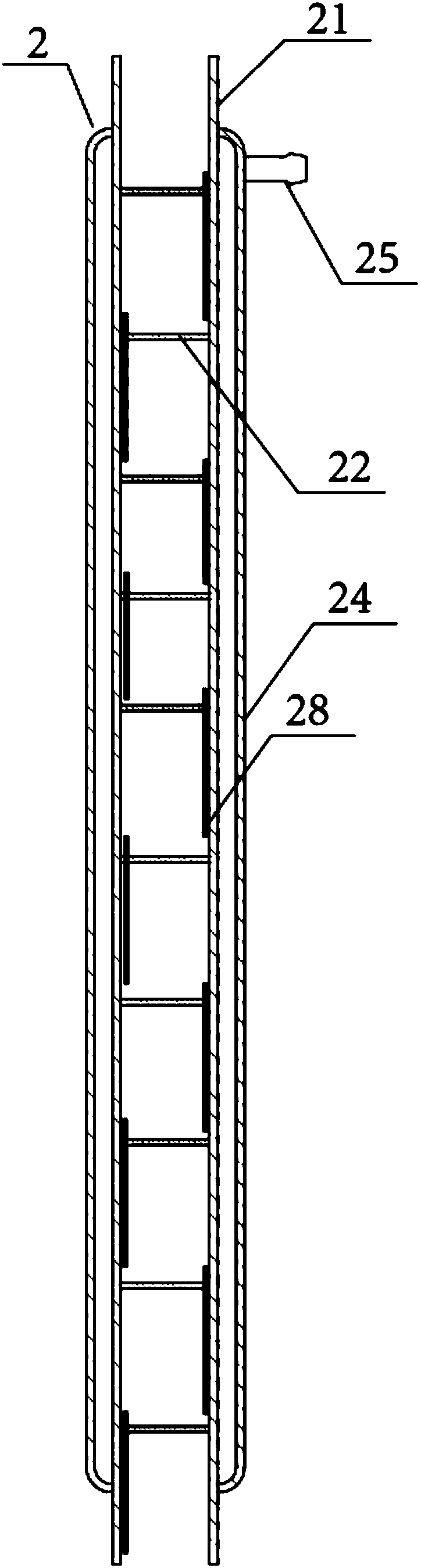

[0046] See attached Figure 1-9 ; An arsenic purification and rectification device, comprising a rectification tower head 1, a rectification tower column 2, a rectification tower kettle 3, and a storage bottle 4, wherein:

[0047] The rectifying tower head includes a blind pipe 11, a reinforced water pipe 12, an outlet pipe 13, an exhaust pipe 14, a primary outlet pipe 15, a final outlet pipe 16, a reinforced water inlet pipe 17, and a temperature measuring pipe 18; the dead pipe includes The inner wall 111, the outer wall 112, the first barrier structure 113, the second barrier structure 114, the third barrier structure 115, and the fourth barrier structure 116; there is a gap between the outer wall and the inner wall; the end of the inner wall is sealed with the outer wall The end face of the inner wall is higher than the end face of the outer wall; the lower part of the outer wall is provided with a water inlet 117 communicating with the gap; the water inlet is higher than ...

Embodiment 2

[0061] On the basis of Embodiment 1, the following technical points are added:

[0062] The inside of the hollow spherical body is provided with a temperature measuring tube 38; the distance between the temperature measuring tube and the bottom of the hollow spherical body is 40mm, see the attached Figure 12 .

Embodiment 3

[0064] The method for arsenic purification using the arsenic purification and rectification device described in Example 2 comprises the following steps:

[0065] (1) Install the existing primary material connection bottle at the outlet of the primary outlet pipe; install a storage bottle at the outlet of the final outlet pipe, and combine the ball bowl structure at the end of the arsenic outlet pipe with the sealing ball head of the final outlet pipe; The outlet of the trachea is equipped with a tail gas collector; the existing vacuum pump is used to evacuate the column and the storage bottle;

[0066] (2) Add the material to be purified into the hollow spherical body from the feed port, and seal the feed port with a sealing plug; then turn on the heating (245°C) and circulating water, and start the rectification process;

[0067] During this process, the rectification steam passes through the circular partition to the escutcheon, and then is discharged from the vent hole comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com