Magnetorheological damper with complex liquid flow passage structure

A magnetorheological damper, liquid flow channel technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem that the best effect cannot be achieved, the adjustable range of damping force is narrow, and the size of the damper It can increase the effective damping length, wide dynamic adjustment range, and extend the length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

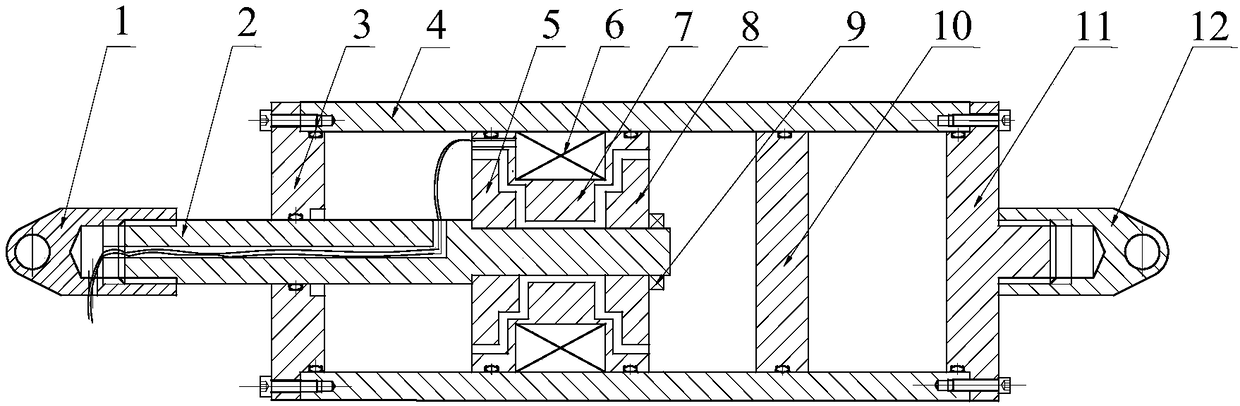

[0017] figure 1 It is a schematic diagram of the structure of the present invention, mainly composed of left lug (1), piston rod (2), damper left end cover (3), damper cylinder (4), piston head left end cover (5), excitation coil (6) , the piston head (7), the right end cover of the piston head (8), the fastening nut (9), the floating piston (10), the right end cover of the damper (11) and the right lifting lug (12).

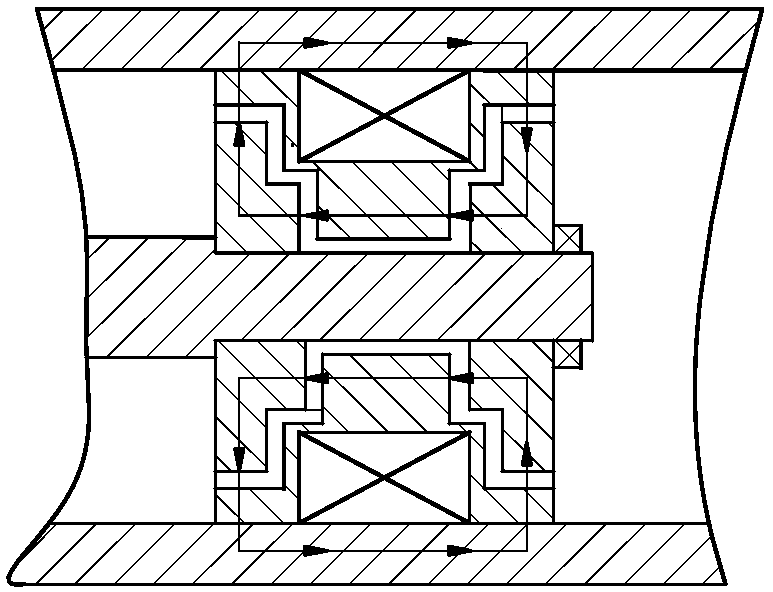

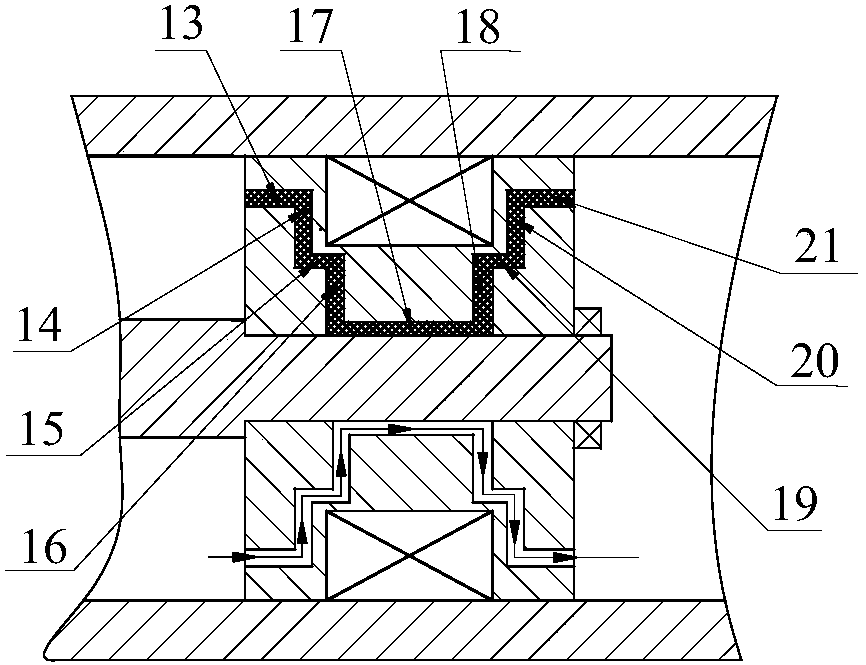

[0018] figure 2It is the magnetic field line distribution diagram of the present invention. Damper cylinder (4), piston head left end cover (5), piston head (7) and piston head right end cover (8) are made of No. 10 steel magnetic material; All the other parts are made of stainless steel non-magnetic material. When the excitation coil (6) is energized, the magnetic field lines generated by electromagnetic induction pass through the left end cover of the piston head (5), the axial circular ring damping gap I (13), and the piston head (7) to the damper cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com