MBUS control circuit for temperature control valve and control method thereof

A control circuit and temperature control valve technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problems of energy waste, low utilization rate of large current, bus current jitter, etc. Improved customer satisfaction, reduced outages and duration of outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with circuit diagrams and specific embodiments.

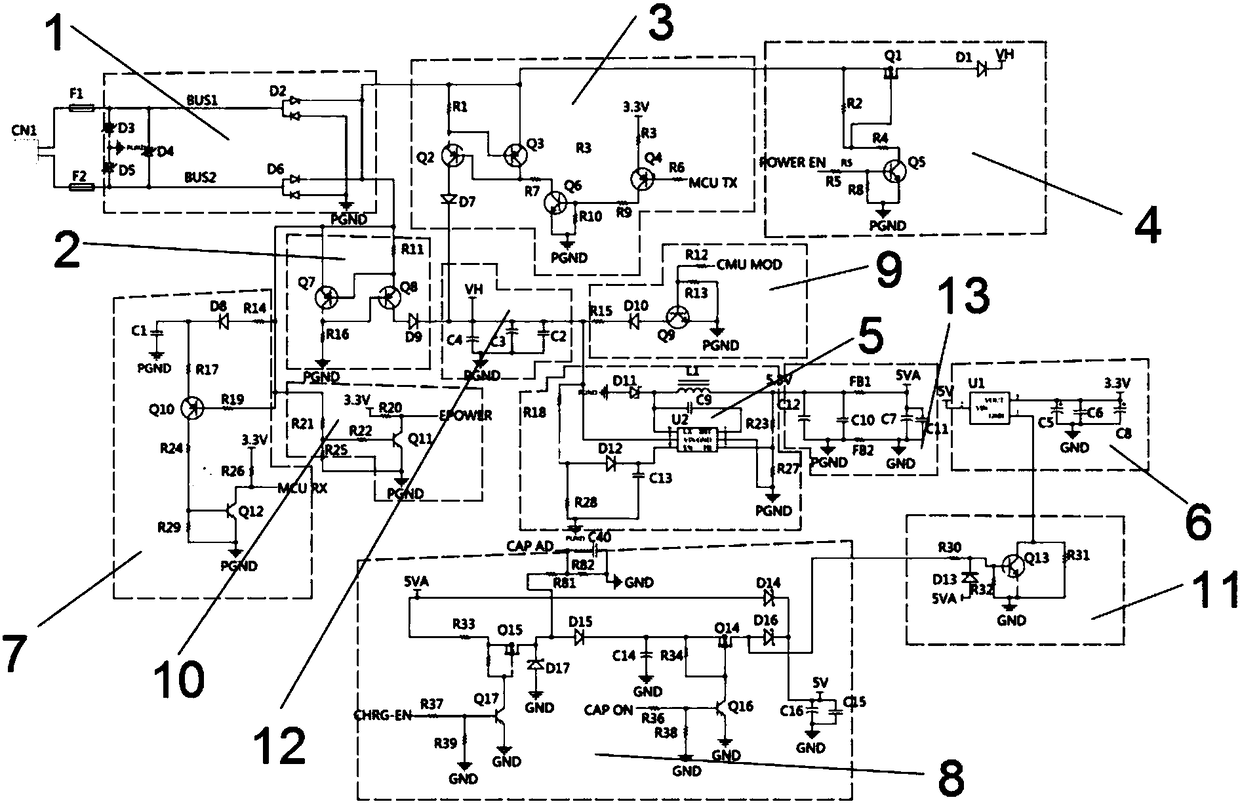

[0020] The MBUS control circuit for the temperature control valve of the present invention includes a single chip microcomputer, a rectifier circuit 1, a power supply circuit, an energy storage circuit 12, a DCDC step-down circuit 5, a filter circuit 13, a stable power supply chip circuit 6, a receiving circuit 7, a super Capacitance control circuit 8, reverse leakage protection circuit 11, energy storage circuit 12 and filter circuit 13, wherein the power supply circuit includes 6mA constant current source 2, 20mA controllable constant current source 3 and bus power supply control circuit 4 and constant current control Circuit 9.

[0021] Such as figure 1 Said, the rectifier circuit is connected to the MBUS bus through two power lines, wherein the 6mA constant current source 2 and the receiving circuit 7 are connected to the fuse F2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com