Fault diagnosis method and device of rolling bearing of low-speed heavy-duty equipment and medium

A rolling bearing, low-speed and heavy-load technology, applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of difficult to effectively extract multiple faults, lack of multi-scale analysis methods for fault characteristics, etc., and achieve good fault state identification effect, Effects of Accurate Characterization and Identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

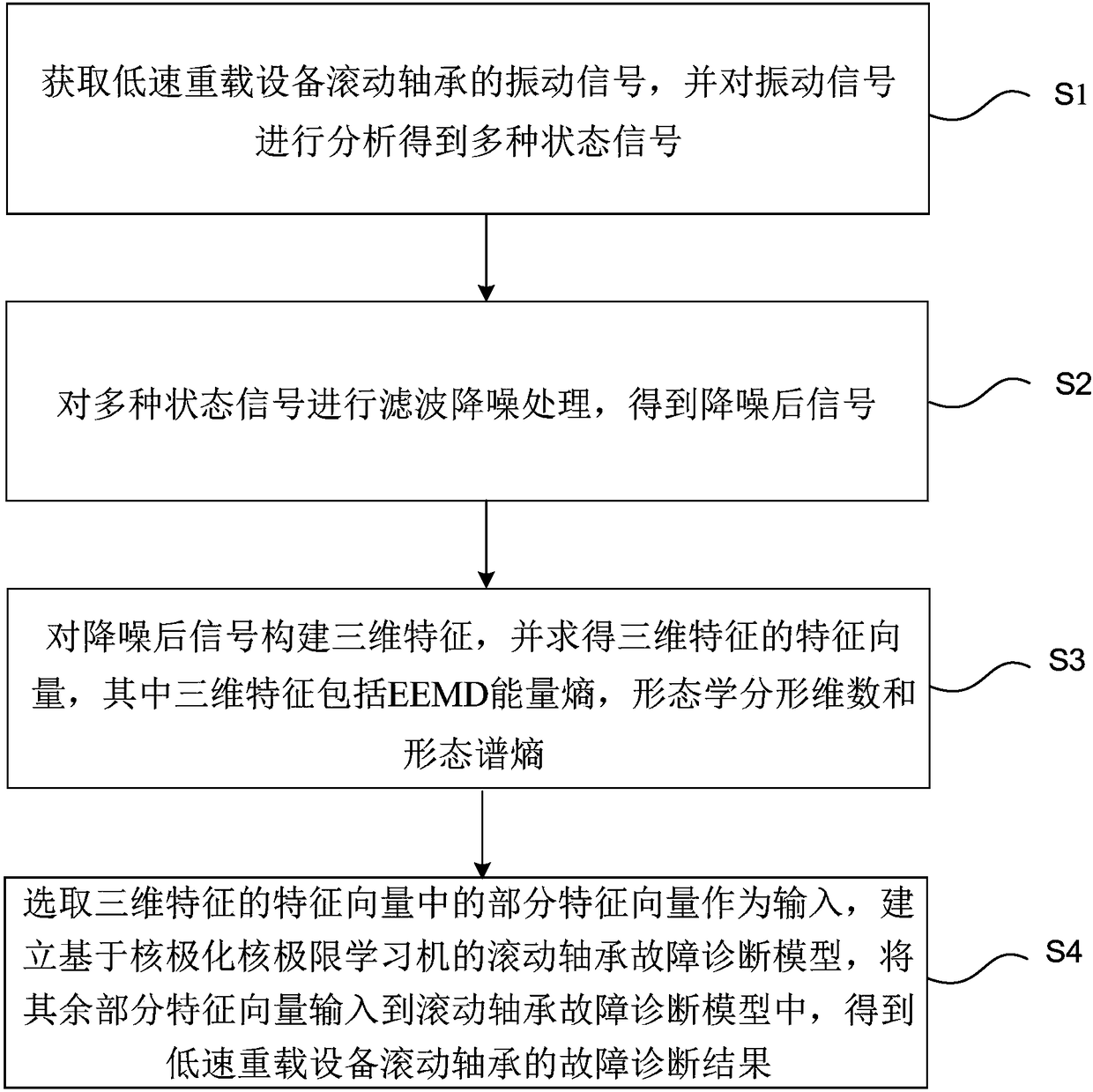

[0055] figure 1 It shows a flow chart of a rolling bearing fault diagnosis method for low-speed heavy-duty equipment provided by an embodiment of the present invention; figure 1 As shown, a method for diagnosing rolling bearing faults of low-speed and heavy-duty equipment provided in this embodiment includes:

[0056] Step S1, obtaining the vibration signal of the rolling bearing of the low-speed heavy-duty equipment, and analyzing the vibration signal to obtain various state signals;

[0057] Step S2, performing filtering and noise reduction processing on the various state signals to obtain a signal after noise reduction;

[0058] Step S3, constructing a three-dimensional feature for the denoised signal, and obtaining a feature vector of the three-dimensional feature, wherein the three-dimensional feature includes EEMD energy entropy, morphological fractal dimension and morphological spectral entropy;

[0059] Step S4, select part of the eigenvectors in the eigenvectors of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com