Metal separation device for construction waste

A technology for metal separation and construction waste, applied in the direction of solid separation, magnetic separation, separation methods, etc., can solve the problems of the reduction of the working efficiency of the crusher, and achieve the effect of improving the working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

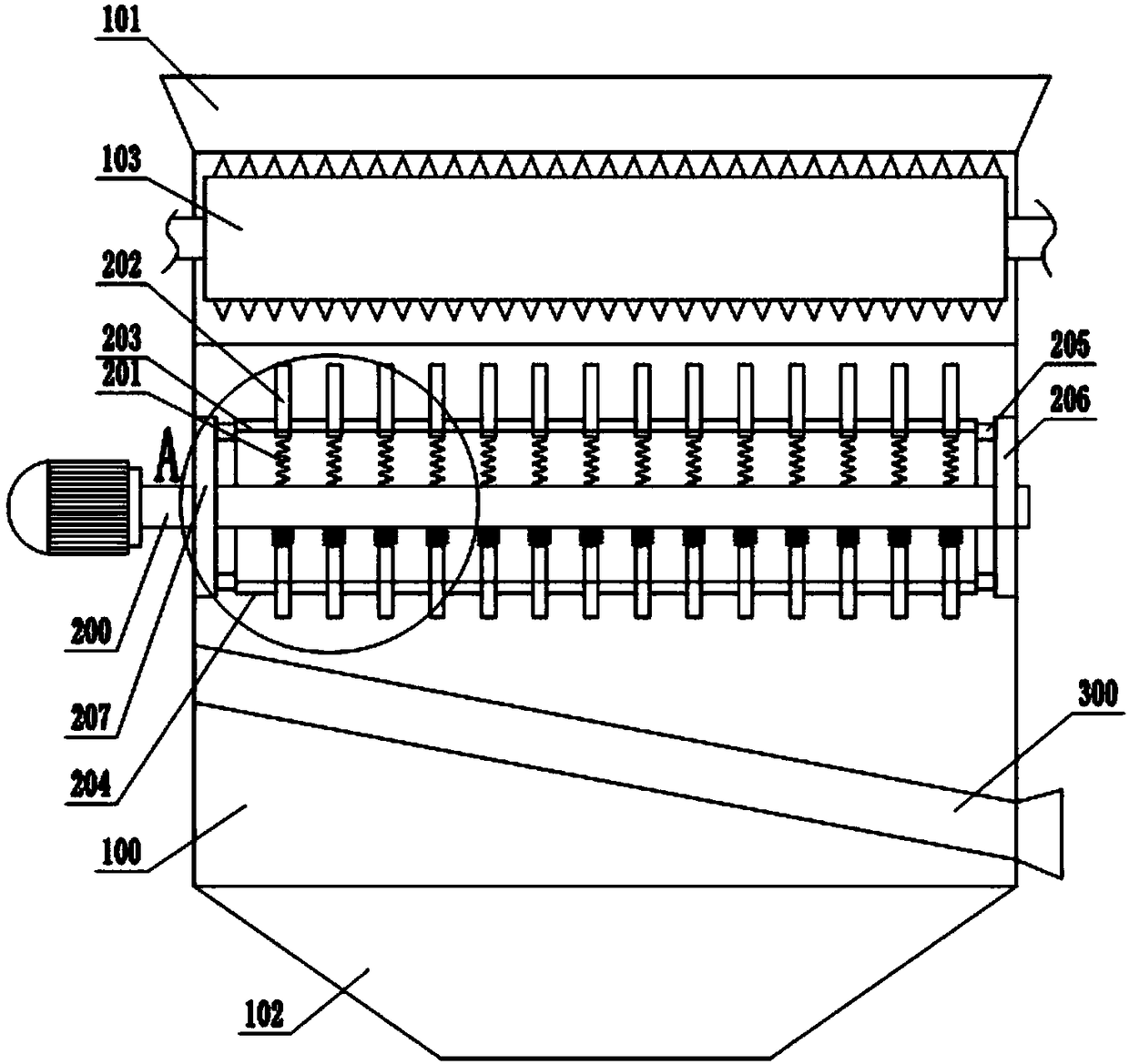

[0031] Such as figure 1 Shown is embodiment one of the present invention, has announced construction waste metal separating device, comprises the crushing box casing 100 that is fixed on the frame, and the upper end of casing 100 is provided with the feeding hopper 101 that dumps construction waste, and casing 100 The lower end of the tank is provided with a discharge hopper 102 for the discharge of crushed and separated construction waste. A pair of motor-driven first crushing rollers 103 and second crushing rollers 104 are provided in the box body 100 near the bottom of the feed hopper 101. The two crushing rollers The surface of the crusher is equipped with conical teeth for crushing construction waste, and the two crushing rollers rotate in opposite directions and mesh with each other.

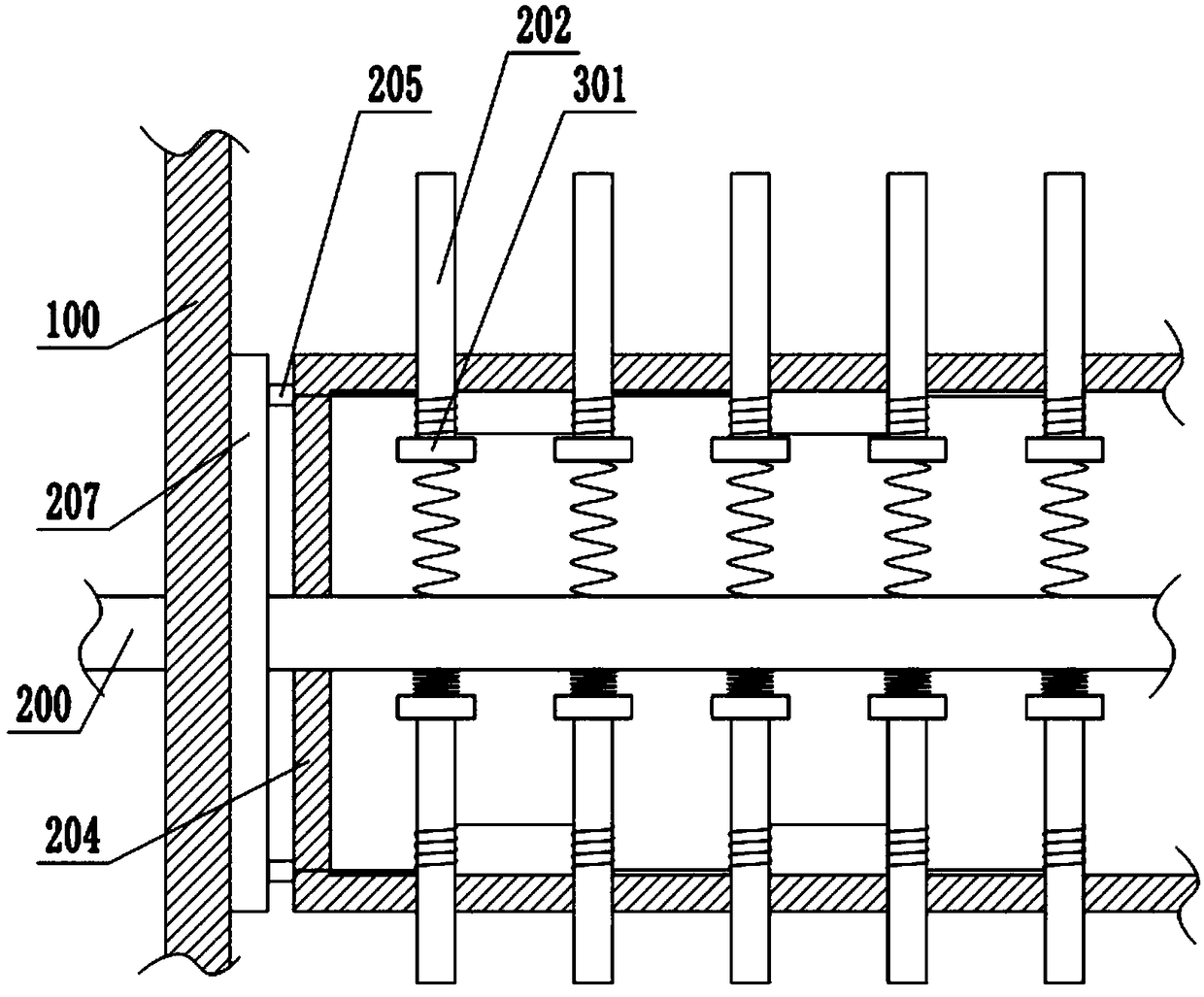

[0032]Just below the first crushing roller 103 is provided with a support shaft 200 driven by a motor. The support shaft 200 in the present invention is a permanent magnet. The installatio...

Embodiment 2

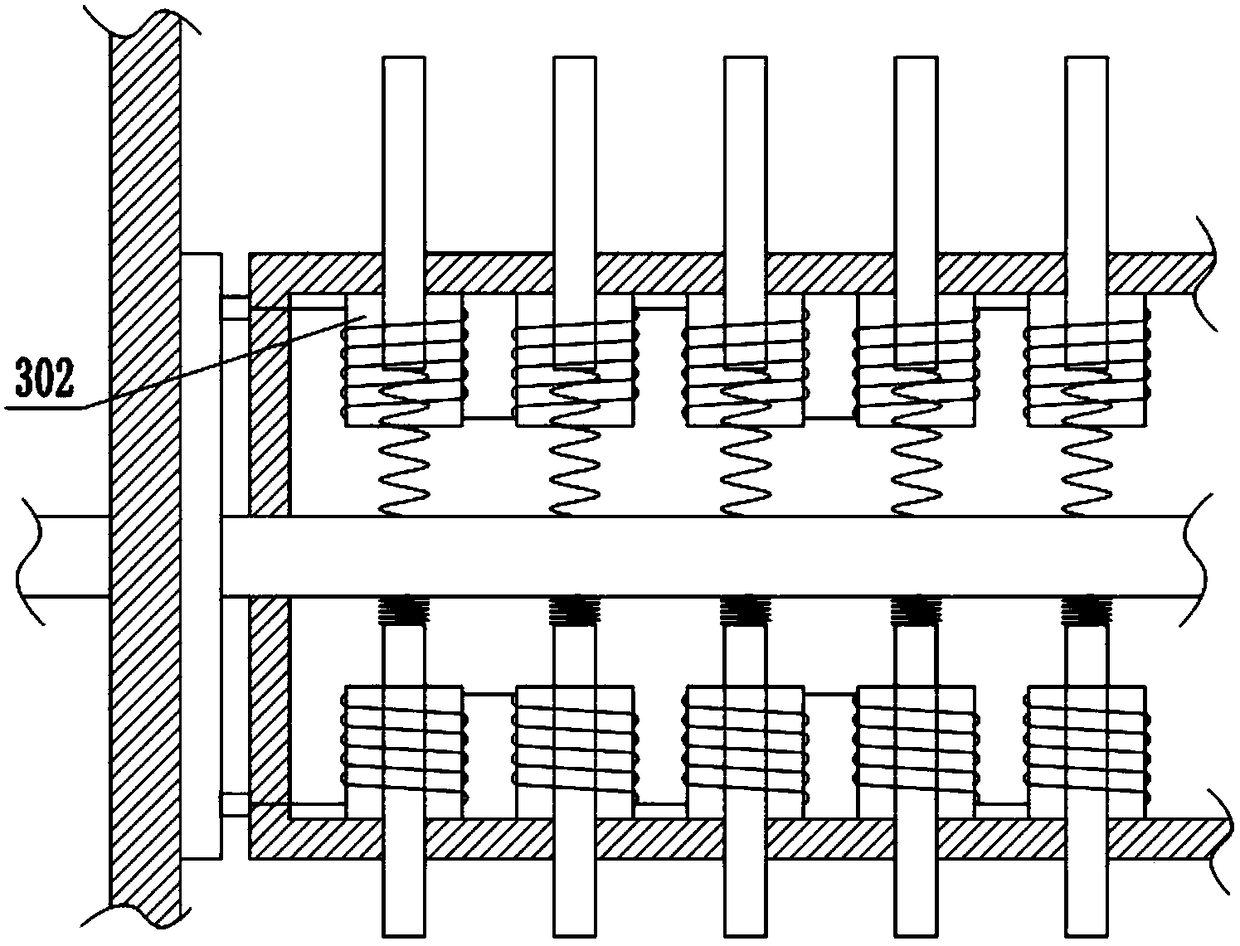

[0038] Such as image 3 Shown is Embodiment 2 of the present invention, and the difference from Embodiment 1 is: a sleeve 302 fixed on the inner wall of the rotating shaft 204 is provided outside the iron core 202, and the coil is wound on the outer wall of the sleeve 302; Figure 4 As shown, a thread groove 303 is provided on the outer wall of the iron core 202 , and a slider 304 slidably connected to the thread groove 303 is fixed on the inner wall of the sleeve 302 .

[0039] During the specific implementation, the difference from the implementation process of the first embodiment is that: when the coil is energized and de-energized, the iron core 202 moves in a spiral trajectory in the connection hole.

Embodiment 3

[0041] Such as Figure 5 Shown is Embodiment 3 of the present invention, and the difference from Embodiment 1 and Embodiment 2 is that in order to reduce the dust flying after the construction waste is crushed, an air suction port 305 is provided on the side wall of the box 100 below the second crushing roller 104 , the air suction port 305 is connected to a dust removal device 307 through a pipeline 306 , the dust removal device 307 includes an air pump and a filter bag, and the filter bag is connected to a water tank 308 through a pipeline 306 .

[0042] During concrete implementation, before this device carries out crushing and crushing construction waste, fill water in water tank 308, make pipeline 306 extend into water, start the suction pump in the dust removal device 307 afterward, the dust that produces in the crushing process and support shaft 200 rotate The dust brought up by the agitation enters the pipeline 306 from the air suction port 305 by the adsorption force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com