Oil-water cyclone separator with degassing function

A cyclone separator and separator technology, applied in liquid separation, cyclone devices, separation methods, etc., can solve problems such as increasing the degree of interphase mixing and turbulence, changing flow and separation conditions, and adversely affecting the separation performance of cyclones. , to achieve the effect of avoiding adverse effects and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

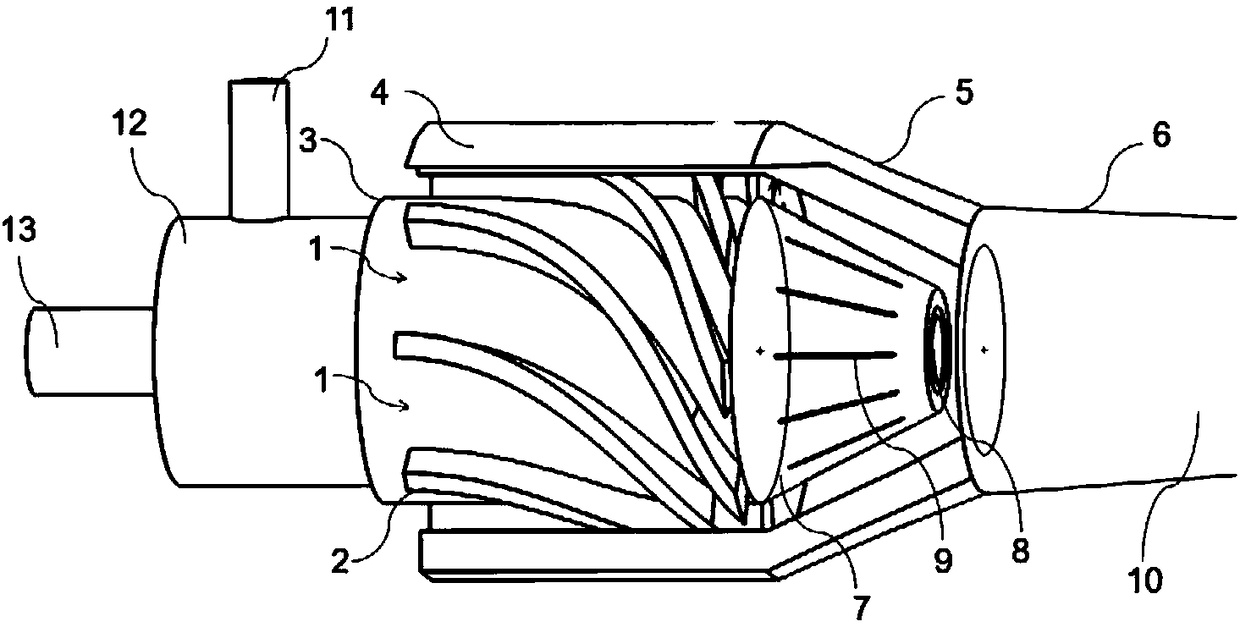

[0018] The oil-water cyclone separator with pre-degassing function of the present invention, its preferred embodiment is:

[0019] The oil-water cyclone separator with degassing function includes a spinner, a degasser and a separation chamber which are surrounded by the outer tube of the separator and connected in sequence. The spinner and the degasser use hollow chambers inside. The hollow chamber is used as an exhaust chamber, the top of the exhaust chamber is provided with an exhaust pipe, the central axis of the exhaust chamber is provided with an oil discharge pipe, and the oil discharge pipe is separated from the oil discharge hole at the bottom of the degasser. The cavity is connected, and the tail of the separation cavity is provided with a drain pipe;

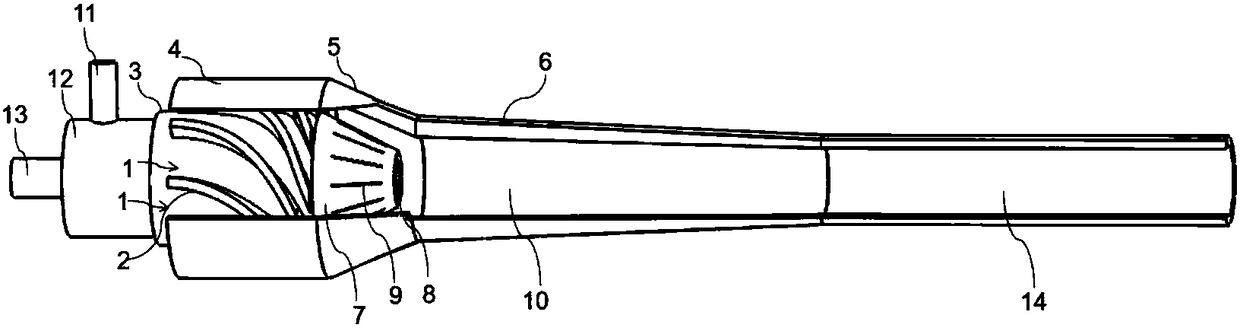

[0020] The outer pipe of the separator includes a cylindrical section, a large cone section, a small cone section and a straight pipe section connected in sequence, and there is a smooth transition between each section...

specific Embodiment

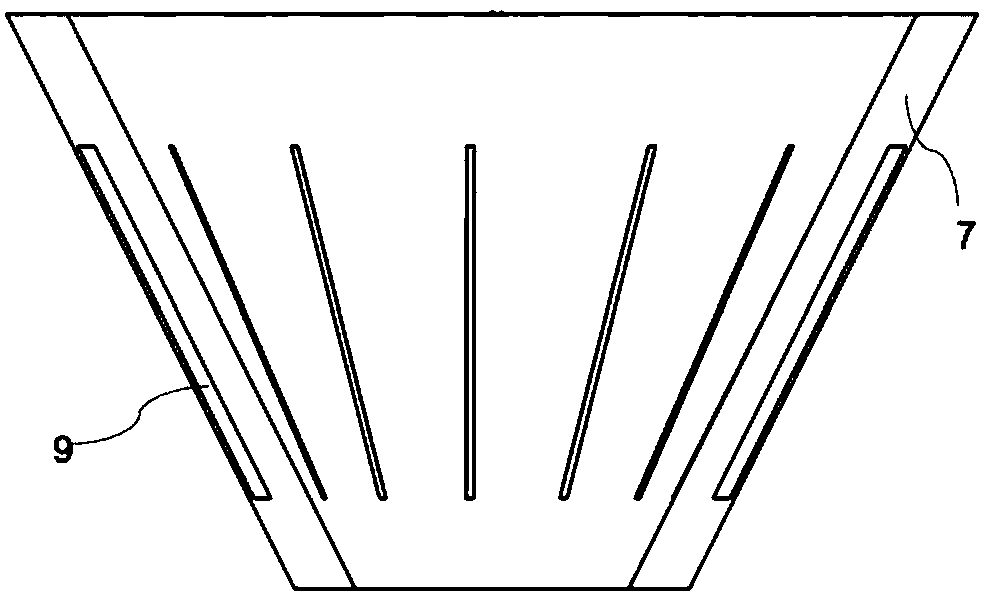

[0031] Such as figure 1 As shown, the embodiment of the present invention provides an oil-water cyclone separator with a pre-degassing function, which is composed of an outer tube of a cyclone separation chamber, a cyclone 3 and a degasser 7 . The spinner 3 is composed of a column-shaped blade carrier and a guide vane 2. The guide vane can adopt an arc alignment, a power function alignment or a helical blade, and the length of the blade in the axial direction is equal to the cylindrical section of the outer tube of the separator. length, the vanes in the radial direction are interference fit with the outer tube of the separator and the vane carrier, and the vanes are evenly distributed in the circumferential direction. The outer pipe of the cyclone separator is composed of a cylindrical section 4 of the outer pipe of the separation chamber, a large cone section 5 of the outer pipe of the separation chamber, a small cone section 6 of the outer pipe of the separation chamber, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com