Frameless combination type permanent magnet synchronous linear motor direct-driven roll-forging machine

A permanent magnet synchronous linear and combined technology, which is applied to the driving device of forging presses, forging presses, forging presses, etc., can solve the problem that the moving positions of both ends are difficult to keep consistent, unfavorable for precise processing of rolling parts, and many intermediate transmission parts and other issues, to achieve the effect of reducing energy loss, improving work efficiency, and high-power energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

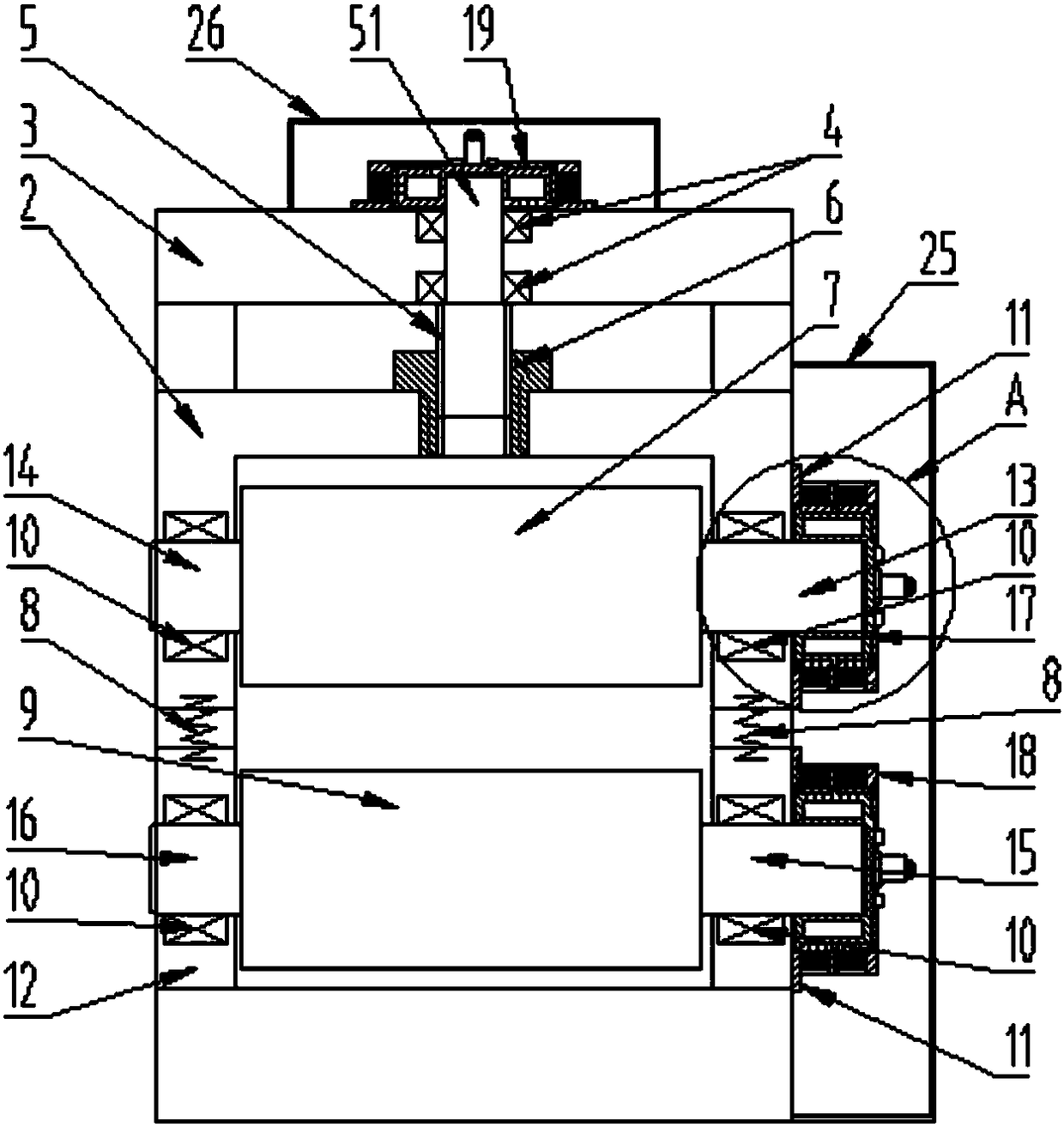

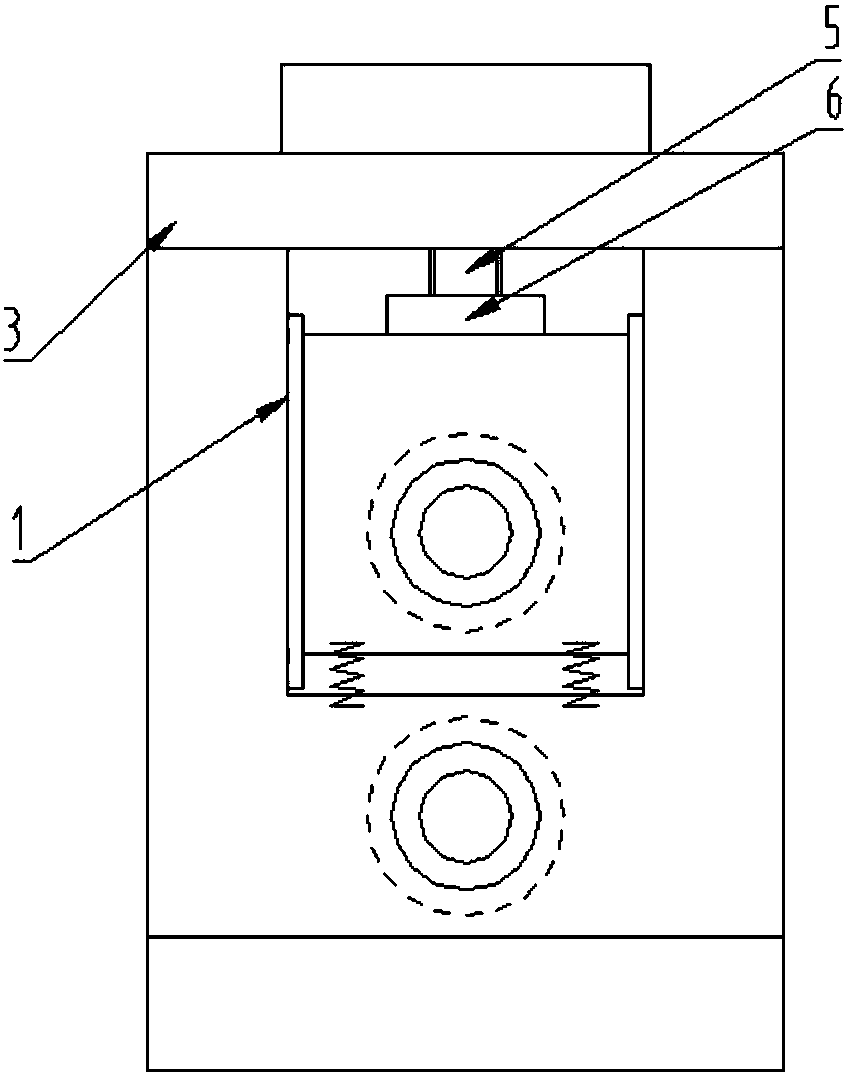

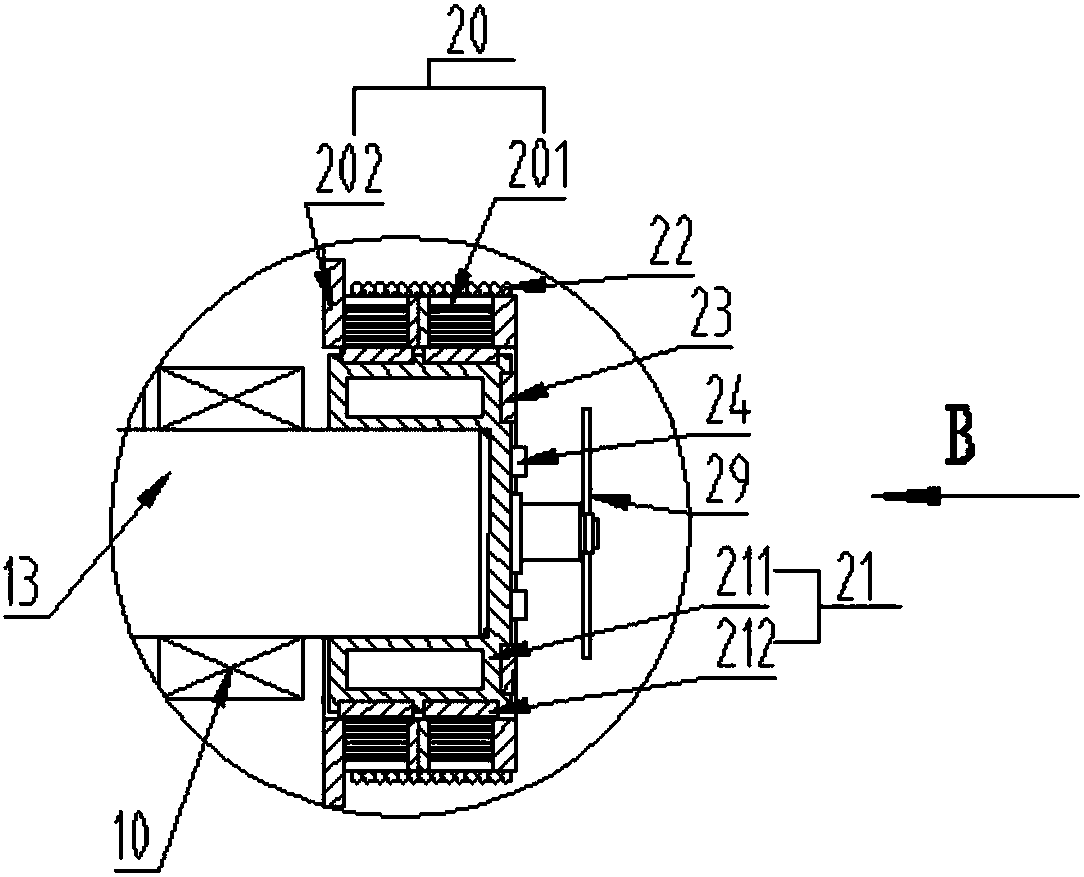

[0038] Such as Figure 1-6 Shown: a frameless combined permanent magnet synchronous linear motor direct drive roll forging machine, including sliding guide rail 1, upper roller support 2, frame 3, bearing 4, screw rod 5, nut 6, upper roller 7. Compression spring 8, lower roller 9, roller bearing 10, motor bracket 11, lower roller support 12, the upper roller support 2 is connected with the sliding guide rail 1, and the upper roller 7 passes through the upper roller Wheel drive shaft 13 and upper roller axle 14 are installed on the upper roller support 2, and described lower roller 9 is installed on the lower roller support 12 by lower roller drive shaft 15 and lower roller axle 16, and described upper roller A compression spring 8 is arranged between the wheel support 2 and the lower roller support 12; the screw mandrel 5 is installed on the frame 3; the upper roller drive shaft 13 and the lower roller drive shaft 15 are respectively connected There is a first frameless combi...

Embodiment 2

[0053] Such as Figure 7 As shown, a frameless combined permanent magnet synchronous linear motor direct-driven roll forging machine, the structure and principle of this embodiment and embodiment 1 are similar, the difference between this embodiment and embodiment 1 is that the rollers in this embodiment The forging machine is driven by a single machine, wherein the lower roller drive shaft 15 is fixedly connected to the second frameless combined permanent magnet synchronous linear motor 18, and the upper roller 7 is connected to the lower roller 9 driven by the linear motor. They are connected by a transmission part 30, and the intermediate transmission part ensures the synchronous movement of the rollers to ensure the precise shaping of the workpiece. The intermediate transmission part can be a gear transmission or a chain transmission.

Embodiment 3

[0055] Such as Figure 8-10 As shown, a frameless combined permanent magnet synchronous linear motor direct-driven roll forging machine, this embodiment is similar to the structure and working principle of embodiment 1 or embodiment 2, and the difference with embodiment 1 or 2 is that The stator assembly 20 in this embodiment includes a stator unit 203 with a fan-shaped disk structure and a disk-shaped stator base 204 , and the rotor assembly 21 includes a disk-shaped rotor base 213 and a disk-shaped magnetic steel substrate 214 .

[0056] The stator unit 203 of the fan-shaped disk structure, the disk-shaped stator base 204 , the disk-shaped rotor base 213 , and the disk-shaped magnetic steel substrate 214 are combined into a frameless combined permanent magnet synchronous disk-shaped linear motor 28 .

[0057] After the power is turned on, the disc-shaped magnetic steel substrate 214 provides an axial rotating magnetic field for the stator unit 203 of the fan-shaped disc stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com