Multi-spraying-head 3D printer

A 3D printer and multi-nozzle technology, applied in the field of 3D printing, can solve the problems of difficulty in meeting the design requirements of assembled products, affecting the quality of workpieces, height adjustment errors, etc., to achieve the effect of simple structure, ensuring design requirements, and fast installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment.

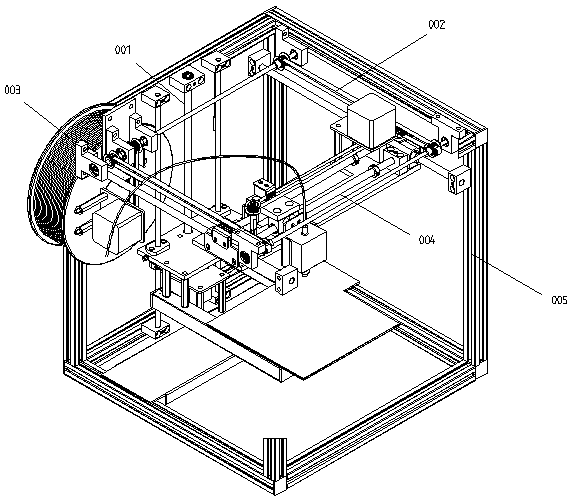

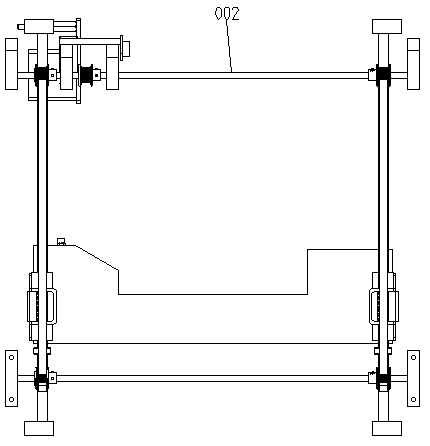

[0021] A multi-nozzle 3D printer of the present invention is mainly composed of a printing platform lifting device 001, a double-toothed belt horizontal moving device 002, a material box 003, a multi-nozzle mount 004, and a printer frame 005.

[0022] The printing platform lifting device 001 is installed on the printer frame 005, the printing platform lifting device 001 is connected with the double-toothed belt horizontal moving device 002, and the double-toothed belt horizontal moving device 002 is connected with the multi-nozzle mount 004; the material box 003 is installed On the printer frame 005, the material box 003 is connected with the multi-nozzle mount 004 through the feed pipe 43;

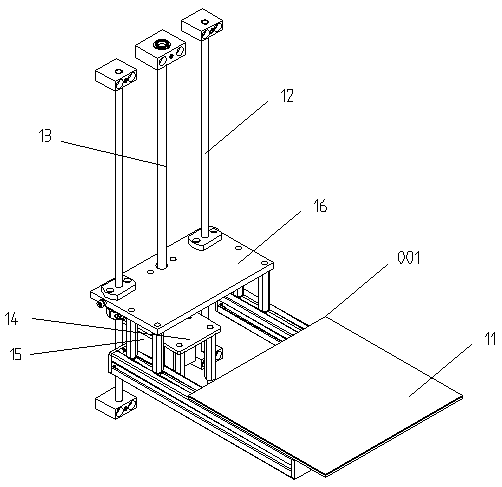

[0023] The printing platform lifting device 001 includes a printing platform 11, a limit guide rail 12, a lifting guide rail 13, a lifting motor bracket 14, a lifting servo motor 15, and a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com