Rotatable 3D printer

A 3D printer and rotary technology, applied in the direction of 3D object support structure, additive manufacturing, processing drive device, etc., can solve the problems of narrow operating space and inflexibility of nozzles, and achieve large operating space, large operating range and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

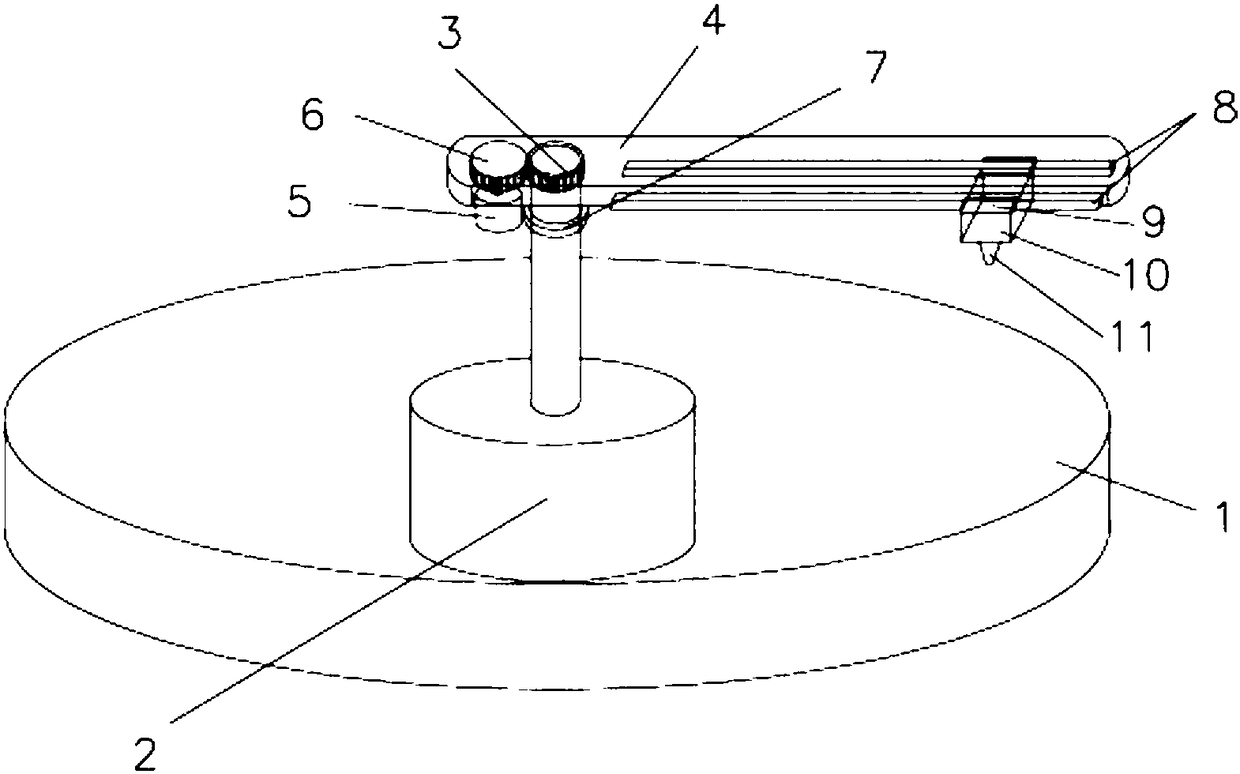

[0015] refer to figure 1 , a rotatable 3D printer described in this specific embodiment, including a workbench 1, a linear motor 2, a gear B3, a rotating arm 4, a motor 5, a gear A6, a bearing 7, a sliding rail 8, a sliding mechanism 9, and a nozzle 10 and nozzle 11, a linear motor 2 is set at the center of the workbench 1, a gear B3 is set on the top of the telescopic shaft of the linear motor 2, and the gear B3 is located in the rotating arm 4, and a motor 5 is set inside one end of the rotating arm 4, and a gear A6 is set on the rotating shaft of the motor 5. The gear A6 meshes with the gear B3, the linear motor 2 telescopic shaft is also provided with a bearing 7, the lower end of the rotating arm 4 is arranged on the bearing 7, two sliding rails 8 are arranged parallel and symmetrically on the inner side of the other end of the rotating arm 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com