Flexible composite anti-explosion blocking wall

A retaining wall and flexible technology, applied in the field of flexible composite explosion-proof retaining walls, can solve problems such as insufficient protection against shock waves and fragments, deformation of supporting frames, and secondary additional hazards, so as to avoid secondary additional hazards and reduce shock waves and thermal damage , The effect of adjustable protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

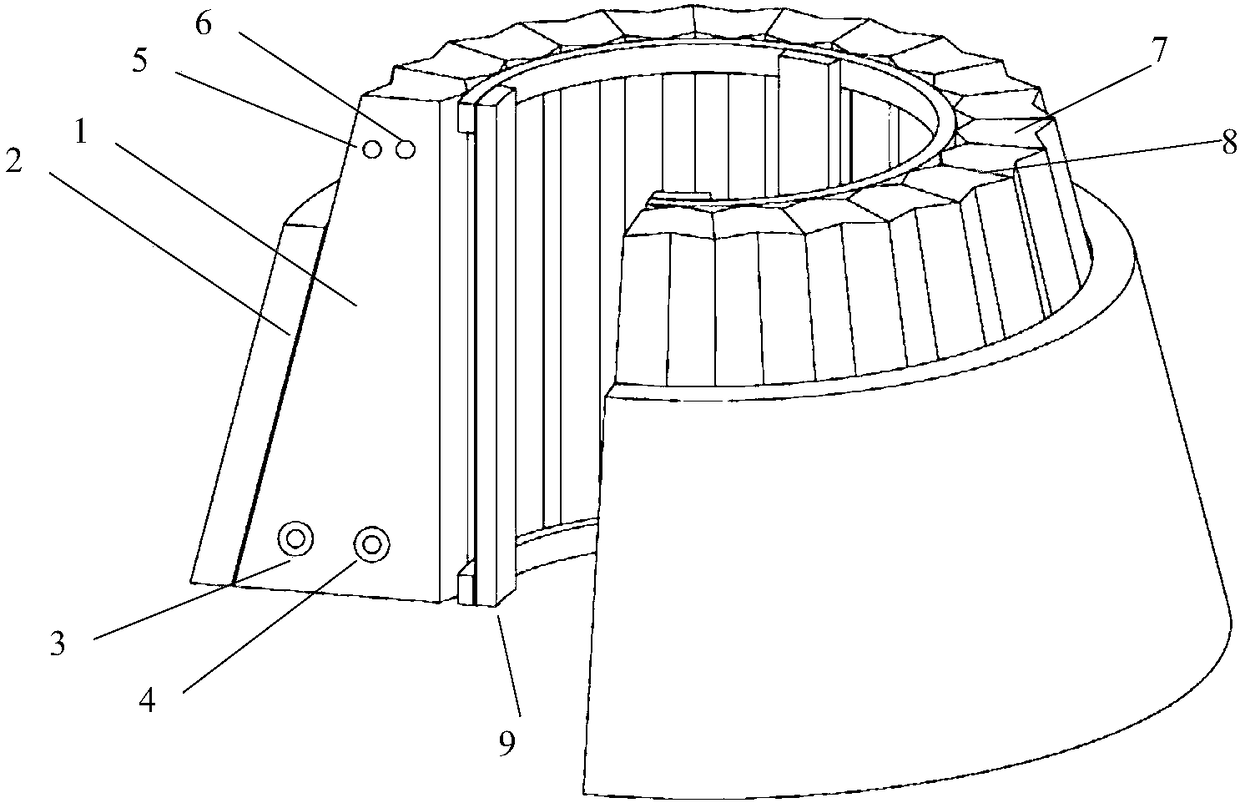

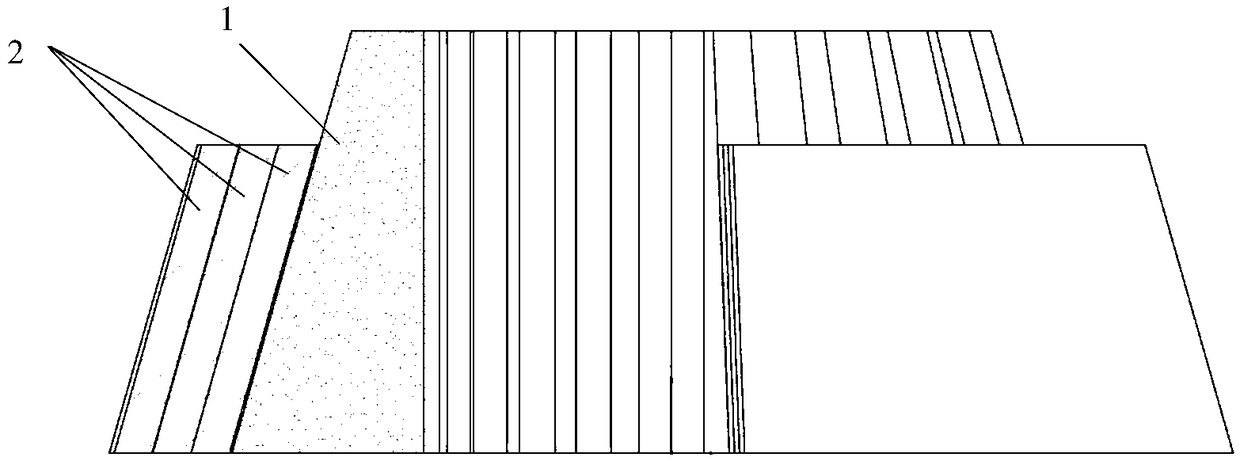

[0034] This embodiment provides a flexible composite explosion-proof retaining wall, see attached figure 1 with figure 2 , is a non-closed annular body, and the corresponding central angle of the annular body is between 180° and 270°. The explosion-proof retaining wall includes: an auxiliary support frame 9 and a liquid layer 1 and a fiber layer 2 installed on the outer circumference of the auxiliary support frame 9 ;

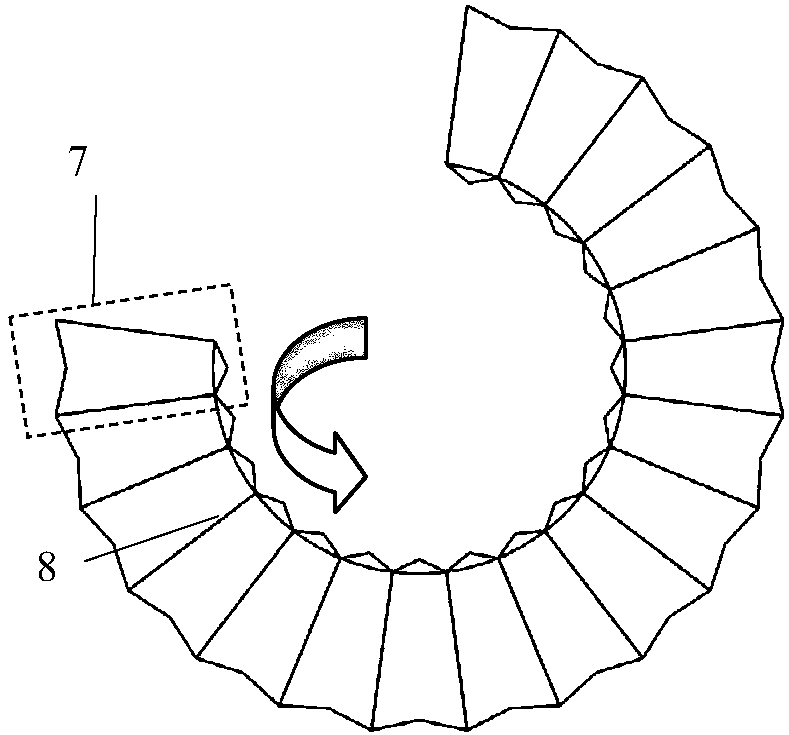

[0035] The liquid layer 1 includes a foldable bag 7, liquid filled in the foldable bag 7 and a reinforcing rib 8 installed in the foldable bag 7; the material of the foldable bag 7 is nylon, and rubber is provided on the inner surface of the foldable bag 7; The lower end of the bag is equipped with a liquid inlet valve 3 for pouring liquid into it and a pressure limiting valve 4 to prevent the pressure in the folding bag 7 from exceeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap