Tunnel second lining micro crack reinforcement method

A technology of micro-cracks and crack directions, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of secondary damage of tunnel lining structure, poor structural durability, low reinforcement strength, etc., and achieve simple, efficient and durable construction Good performance and high reinforcement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

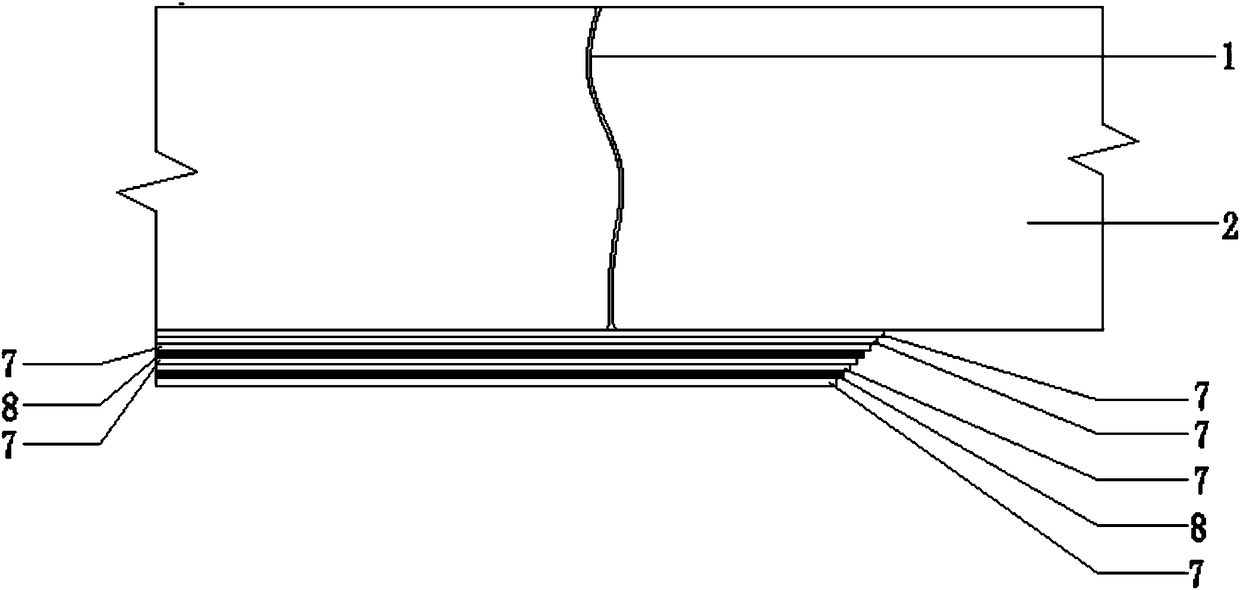

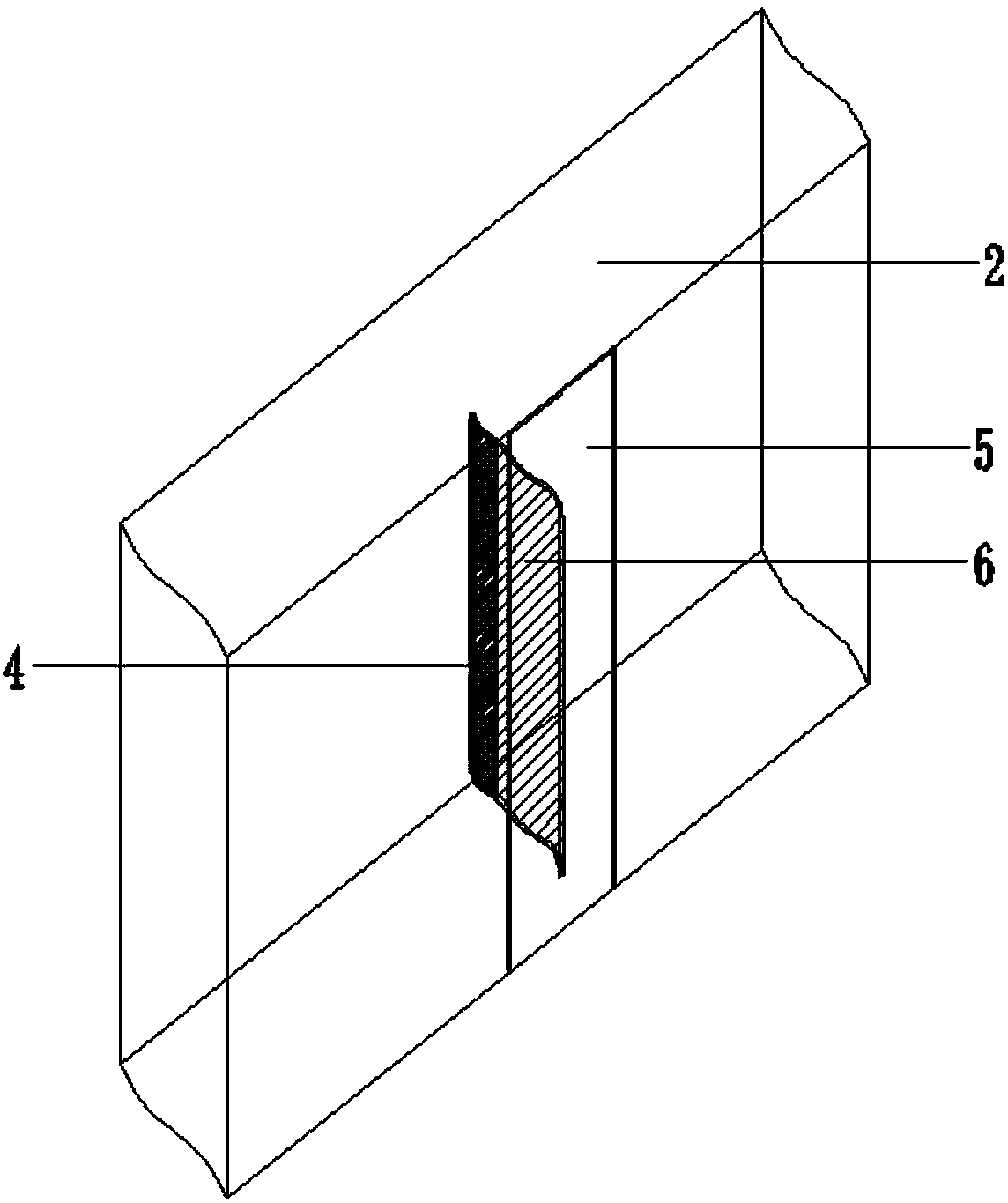

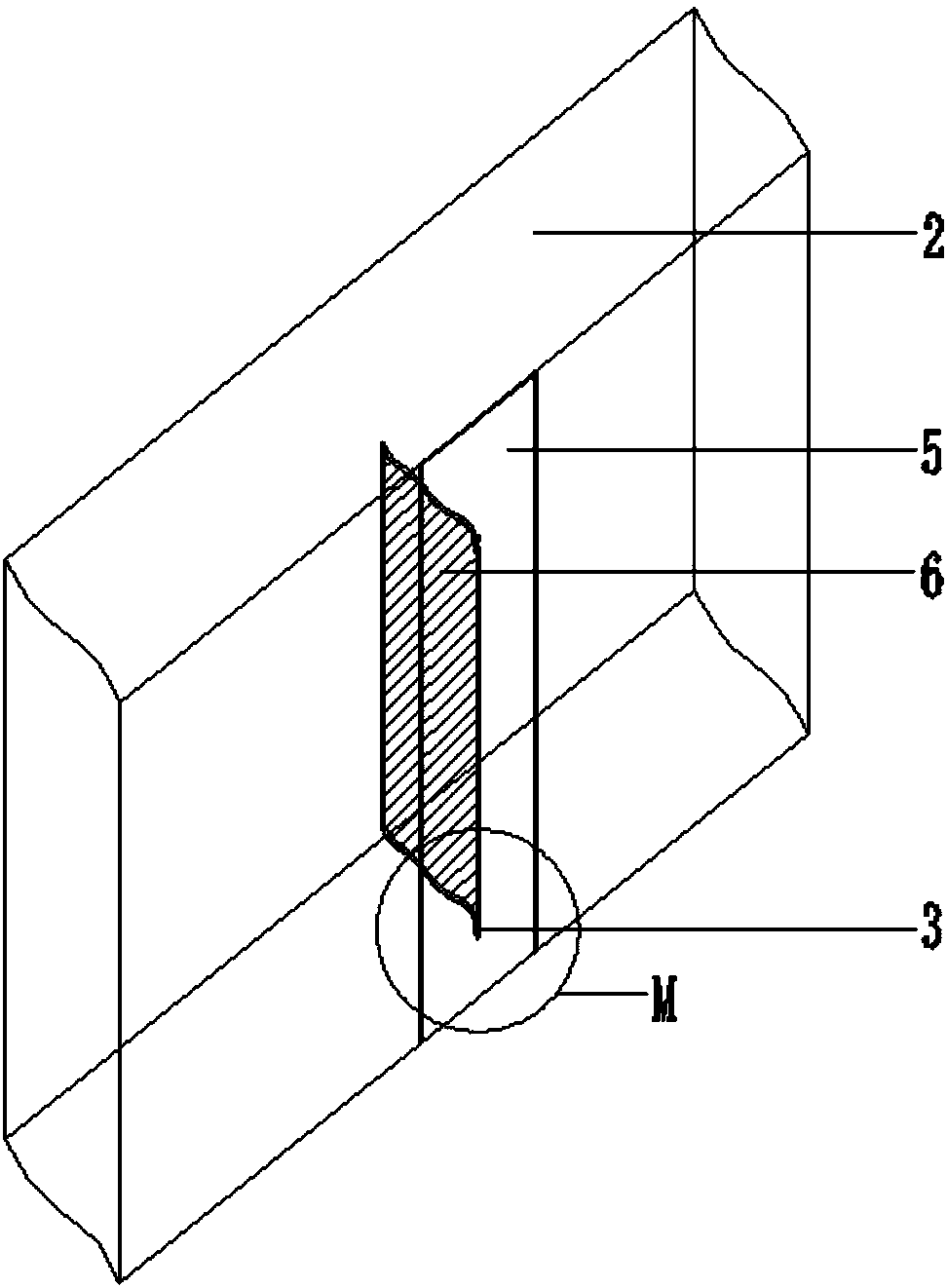

[0057] Such as Figure 1~6 , a method for reinforcing micro-cracks in the secondary lining of a tunnel, comprising the following steps:

[0058] Step 1: Base Treatment

[0059] Step 1-1: Crack treatment

[0060] Use a scraper to remove the mortar and dust adhered to the concrete surface of the second lining 2 along the direction of the crack 1, draw out the direction and length of the crack 1, dig a V-shaped groove along the crack, and clean the V-shaped groove with clean water first, and then use high-pressure air blow off;

[0061] Step 1-2: Bury the grouting nozzle

[0062] Embed grouting nozzles 3 at intervals of 15-30cm along the crack direction; each crack shall not be less than two grouting nozzles to ensure the air in the cracks is discharged;

[0063] Steps 1-3: Plugging Water Seepage

[0064] Such as figure 2, for water se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com