Exhausting ejection device

A technology of ejector and gas turbine, which is applied to the cooling of jet propulsion devices, gas turbine devices, and turbine/propulsion devices, etc., can solve the problems of poor engine bleed effect, gas backflow, and reduced engine test power, so as to prevent the test run. Power drop, increase rate, effect of reducing exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

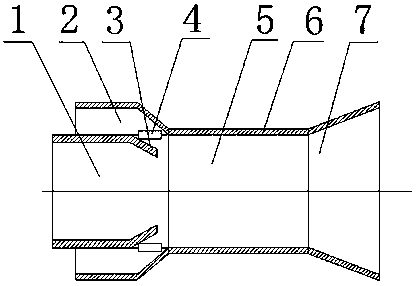

[0017] An exhaust injection device, comprising an exhaust injection tube 6, the left side of the exhaust injection tube 6 is an injection fluid channel 1, the outside of the injection fluid channel 1 is a working fluid channel 2, and the injection fluid channel 1 and working fluid channel 2 are provided with swirl flat tube 4 and windshield 3 , the right side of injection fluid channel 1 is mixing chamber 5 , and the right side of mixing chamber 5 is expansion chamber 7 . An application method of an exhaust injection device is as follows: the exhaust injection device is installed at the exhaust port of the gas turbine, the exhaust pipe of the gas turbine is connected with the injection fluid pipeline 1, and the high-speed cold air fluid enters the exhaust gas through the working fluid channel 2 Inside the gas injection tube 6, due to the high-speed flow of the working fluid, a negative pressure is generated at the junction of the injection fluid channel 1 and the working fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com