Method for determining the number of acquired pressure sensitive paint (PSP) test images

A technology for image acquisition and method determination, applied in aerodynamic tests, machine/structural component testing, measuring devices, etc., can solve problems affecting test efficiency and cost, increase test time and image processing time, and achieve reasonable control The effect of improving test time and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

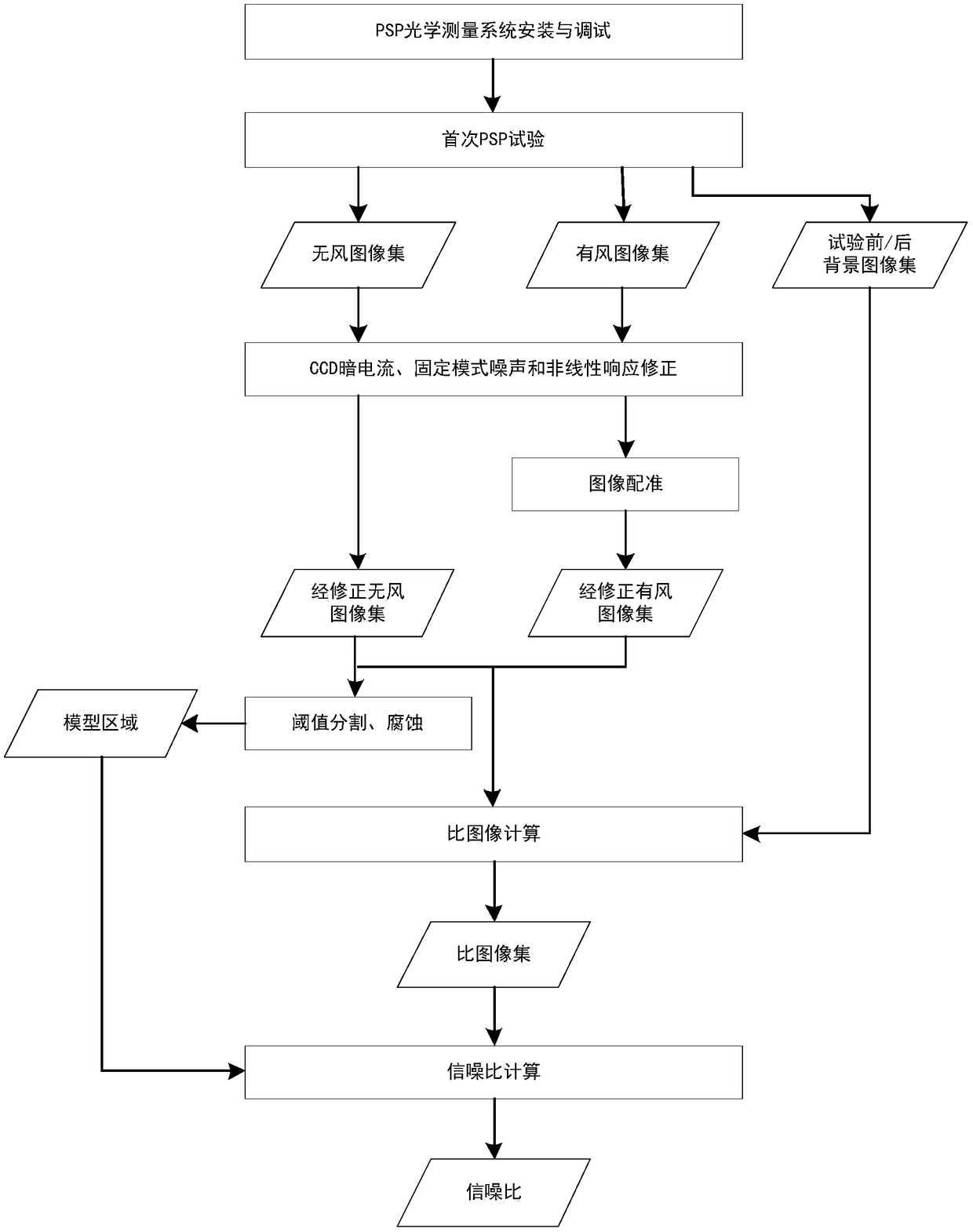

[0033] A method for determining the number of images collected in a single-component pressure-sensitive paint test, such as figure 1 shown, including the following steps:

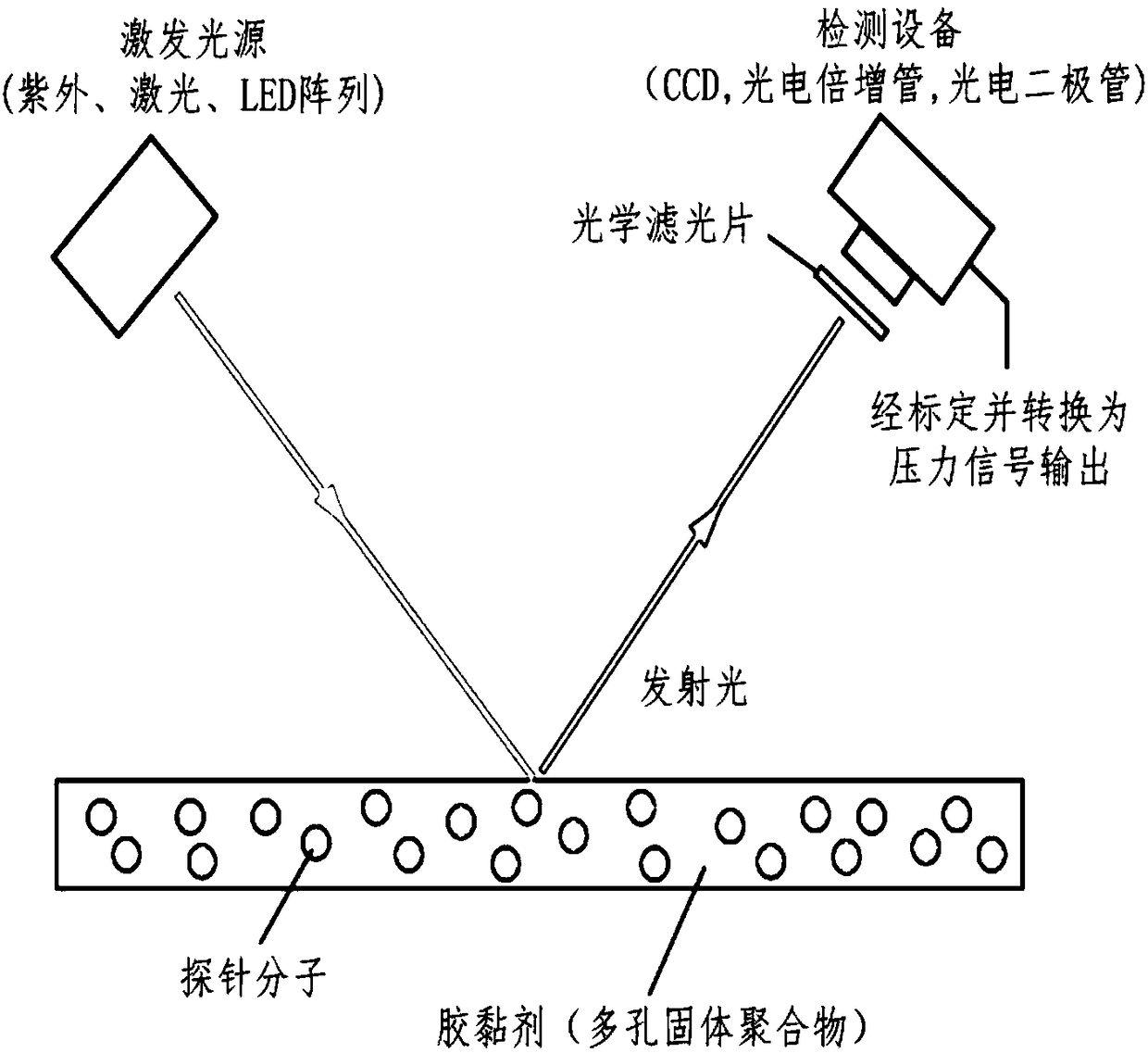

[0034] Step 1. Install the PSP optical measurement system. The main equipment light source and CCD camera of the system are installed perpendicular to the area to be measured in the model; statically debug the PSP optical measurement system: set the camera parameters, including the aperture, under the condition of meeting a certain light intensity , Exposure time and focal length, the setting principle is to set the aperture and exposure time under the condition of ensuring image depth of field and light intensity, after the focal length is adjusted in place, the model PSP measurement area and marking points are clear;

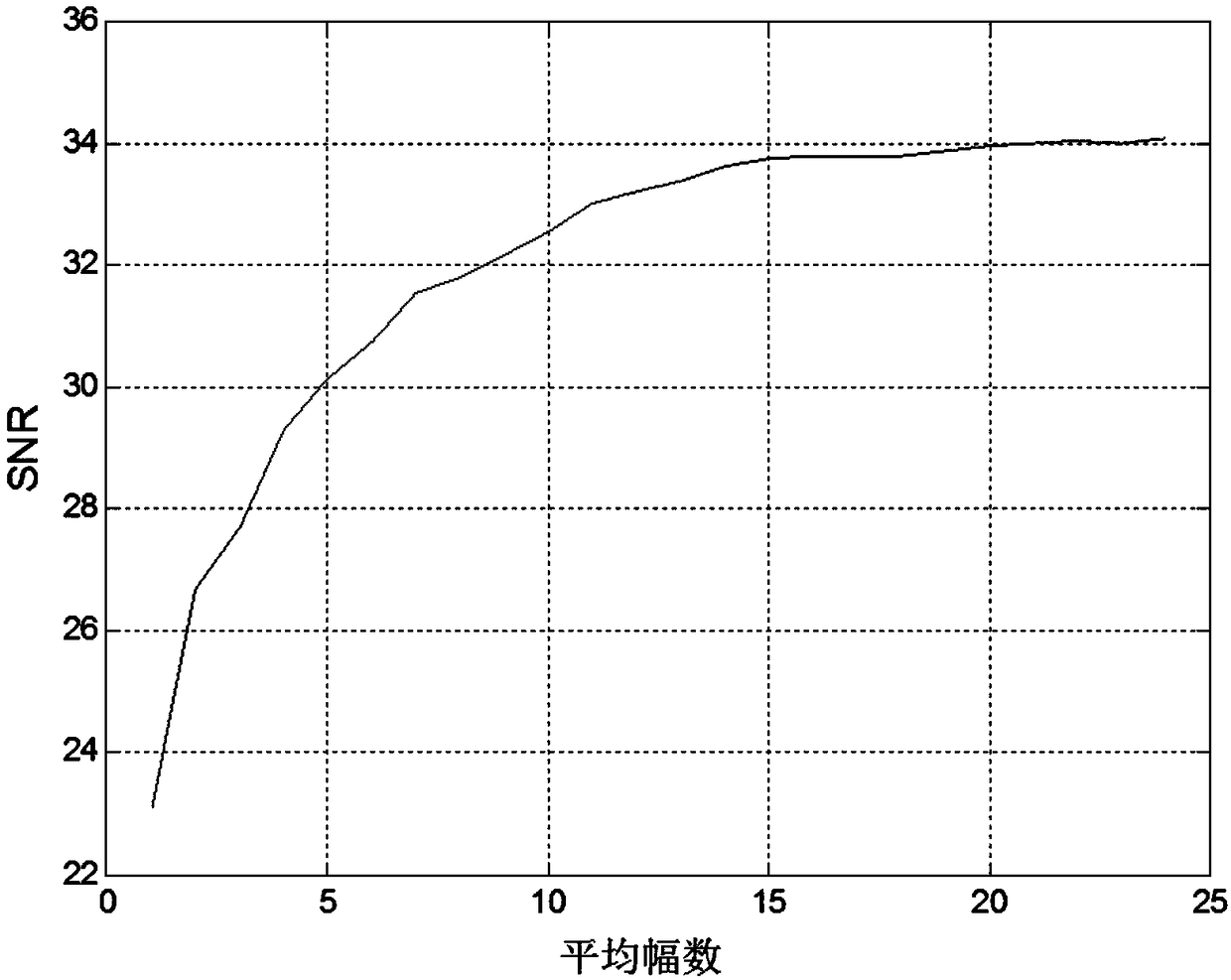

[0035] Step 2. Conduct the first PSP test: use the method of continuously collecting the same number of images, and collect in order to obtain the background image set I before the test b...

Embodiment 2

[0044] A method for determining the number of images collected in a two-component pressure-sensitive paint test. When applicable to a two-component pressure-sensitive paint, in the steady-state pressure measurement test, refer to the steps in Example 1 to calculate the pressure-sensitive components respectively and the signal-to-noise ratio of the reference component images, respectively determine the average number of converged images, and use the larger average number of images as the number of image acquisitions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com