An exhaust muffler with automatic adjustment of magnetorheological damping

A technology of magneto-rheological damping and exhaust muffler, which is applied in the direction of instruments, electrical components, sound-generating equipment, etc., can solve the problems of narrow absorption frequency band, poor high-frequency effect, low sound absorption coefficient, etc., and achieve strong sound absorption and noise reduction ability , absorption frequency bandwidth, and the effect of reducing sound power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

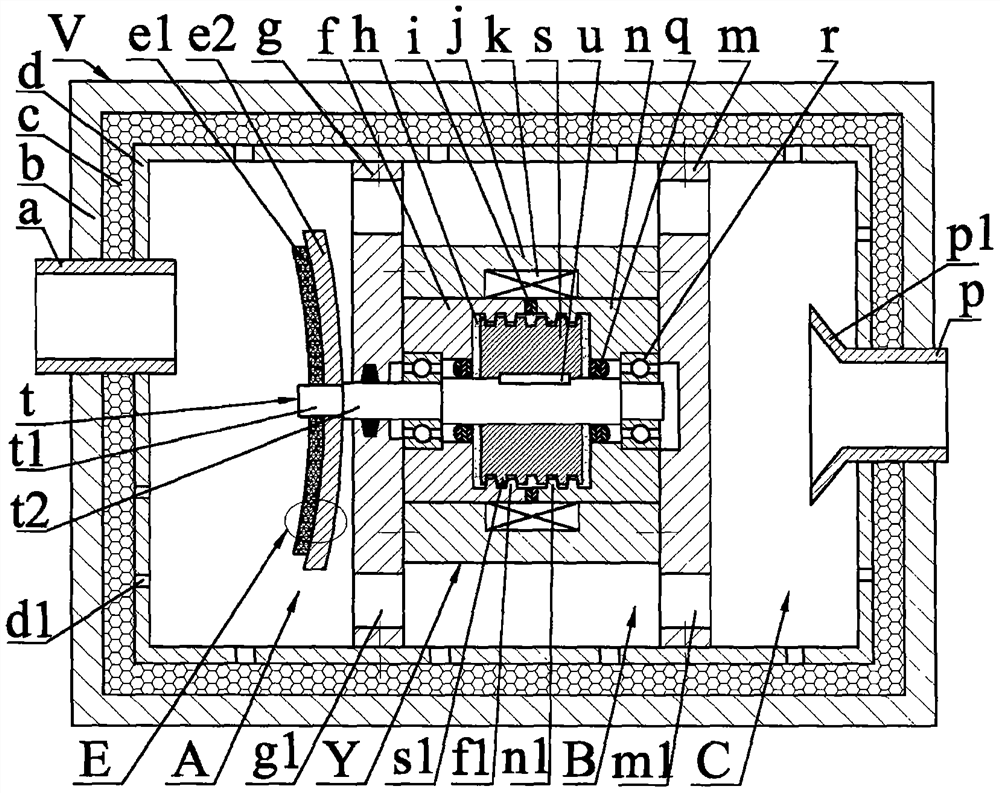

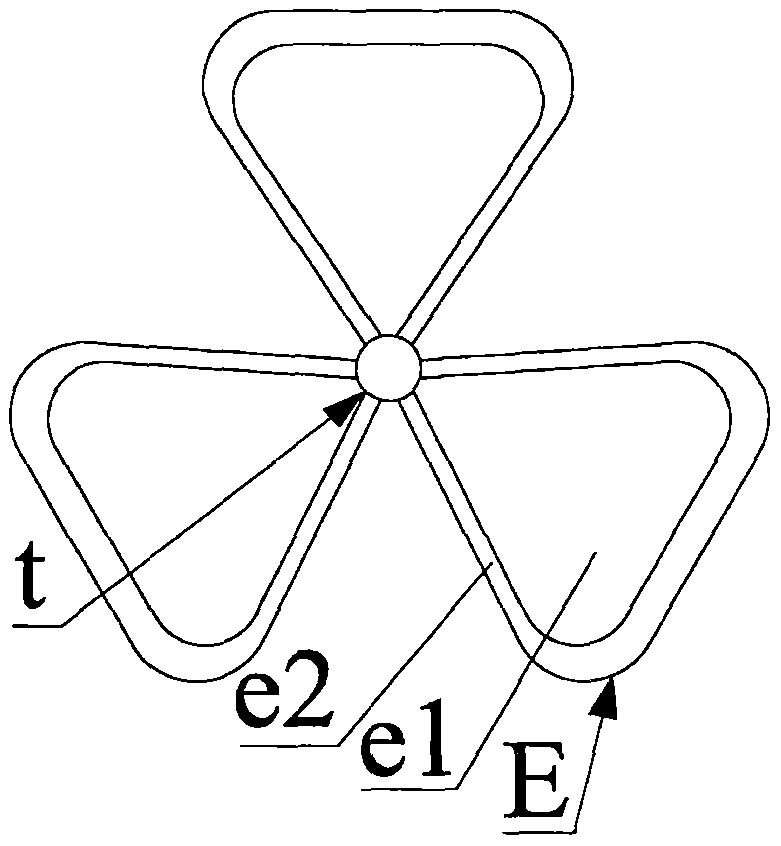

[0012] An exhaust muffler with automatic adjustment of magneto-rheological damping, comprising a hollow cylinder V, an air inlet pipe a is arranged along one end of the cylinder V deviated from the axis, and a cone at the left end is arranged along the axis of the other end of the cylinder V The air outlet pipe p of shape p1; the cylinder V includes the shell b, the felt c and the perforated plate d, and there are a number of air holes d1 on the perforated plate d; the left partition g and the right partition m are arranged along the vertical cylinder The direction of the V axis divides the cylinder V into the first chamber A, the second chamber B and the third chamber C, the inlet pipe a communicates with the first chamber A, and the outlet pipe p communicates with the third chamber C; left There are left flow holes g1 and right flow holes m1 evenly distributed on the partition g and the right partition m; the left partition g is provided with a rotating shaft t coaxial with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com