A piezo-electromagnetic-rheological muffler for marine turbine engines

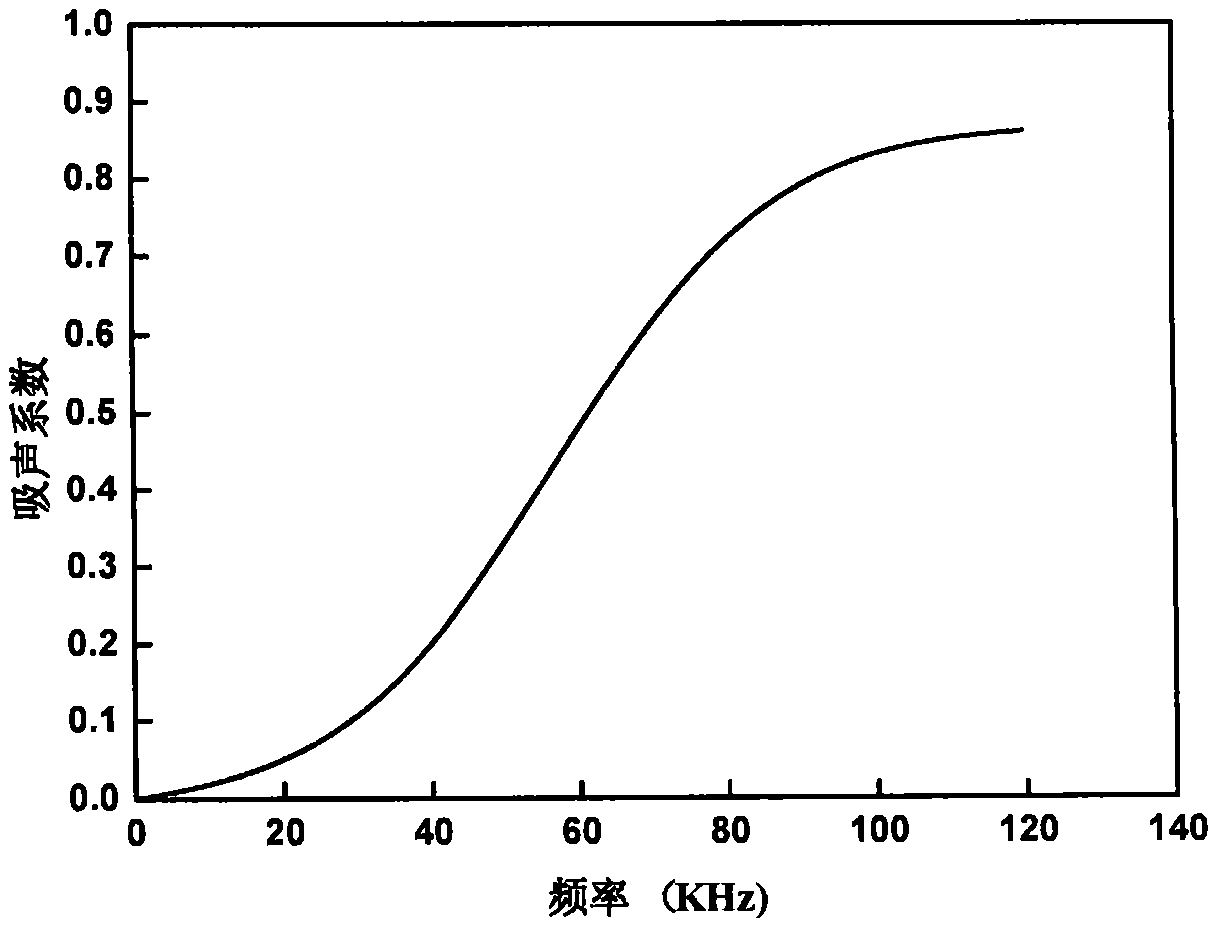

A technology of turbine engine and muffler, which is applied in the direction of engine components, combustion engines, machines/engines, etc. It can solve the problems of unsatisfactory exhaust muffler effect and poor high-frequency effect of the muffler, and achieve sound absorption frequency bandwidth and fast sound energy Transformation, the effect of high sound absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

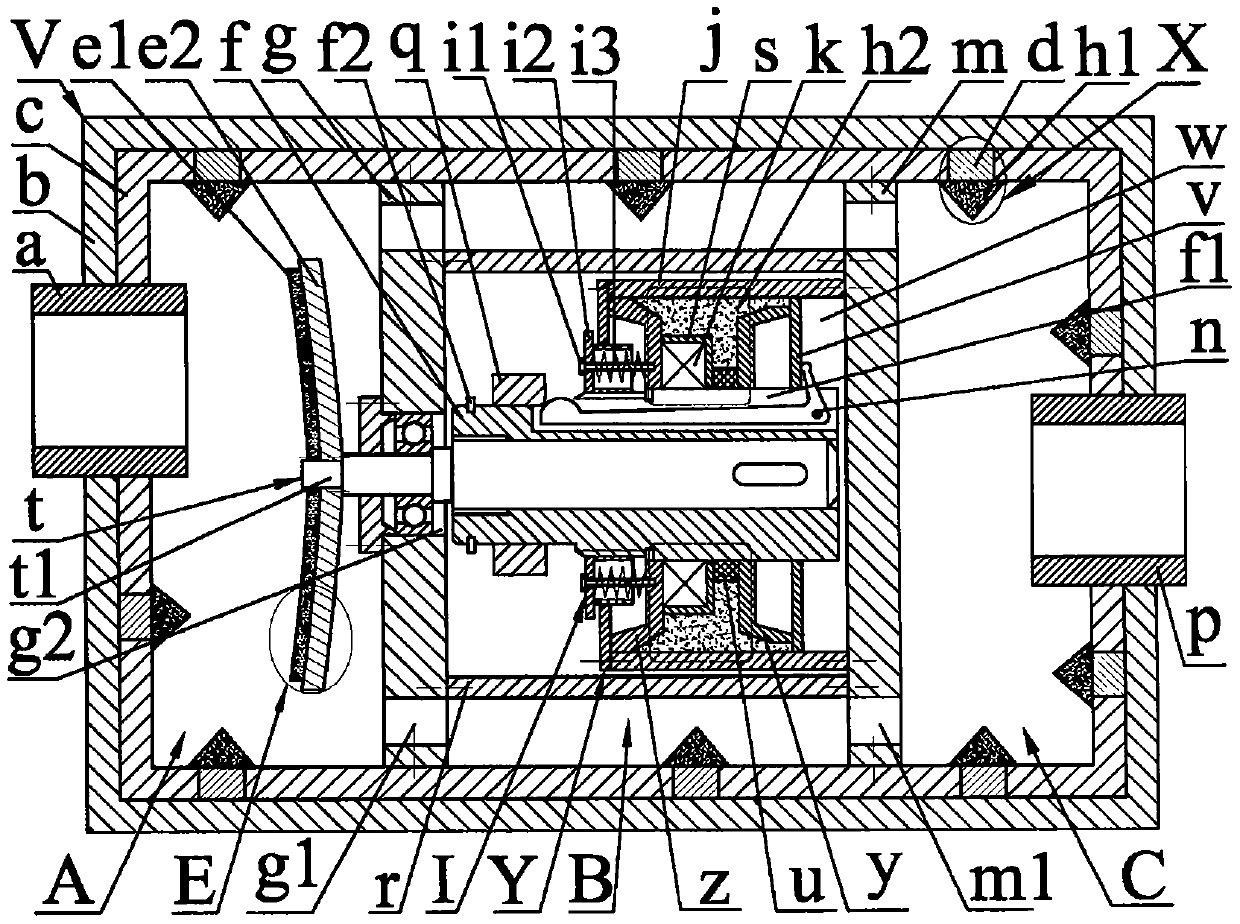

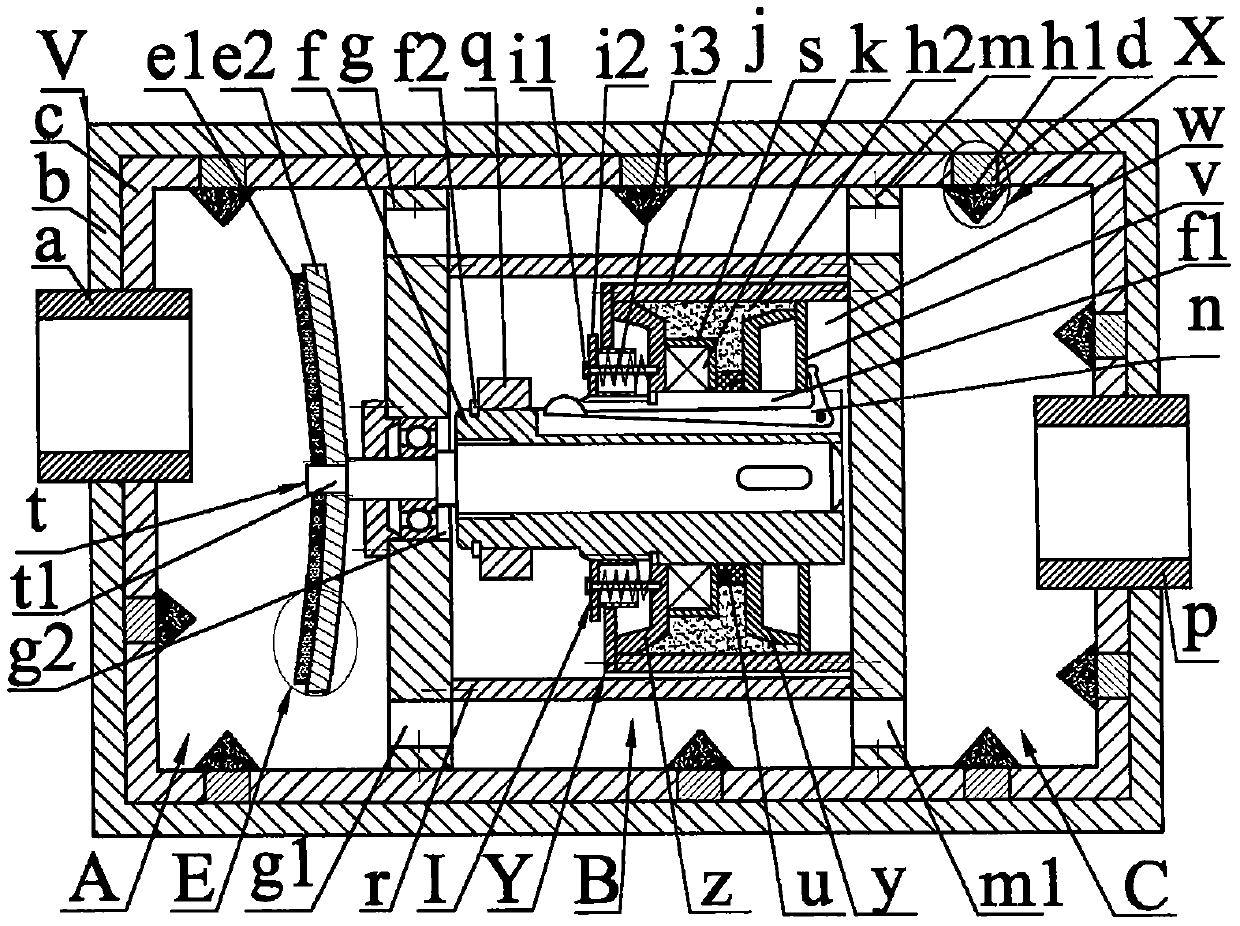

[0013] A piezoelectric electromagnetic rheological muffler for marine turbine engines, comprising a hollow cylinder V, an air inlet pipe a is arranged along one end of the cylinder V off the axis, and an air outlet pipe is arranged along the axis of the other end of the cylinder V p; Cylinder V includes a shell b and a fixed body c. There are several cylindrical holes on the fixed body c, and a magnetic cone X is fixed in the cylindrical hole; the magnetic cone X is covered by a cylindrical permanent magnet d and a magnetized permanent magnet. The conical magnetorheological fluid on the magnet d is composed of h1; the cylinder V is divided into the first chamber A and the second chamber by the left partition g and the right partition m along the vertical direction of the cylinder V axis. body B and the third chamber C, the air inlet pipe a communicates with the first chamber A, and the outlet pipe p communicates with the third chamber C; the left partition g and the right parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com