Device and method for reducing emission of fine particles by acoustic coagulation of compact high-velocity filter

A fine particle, high flow rate technology, applied in separation methods, combined devices, dispersed particle filtration, etc., can solve the problems of low aggregation efficiency of fine particles, unfavorable system installation and layout, unfavorable energy saving and promotion, etc. Effects that grow, increase length, and increase the chance of colliding with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

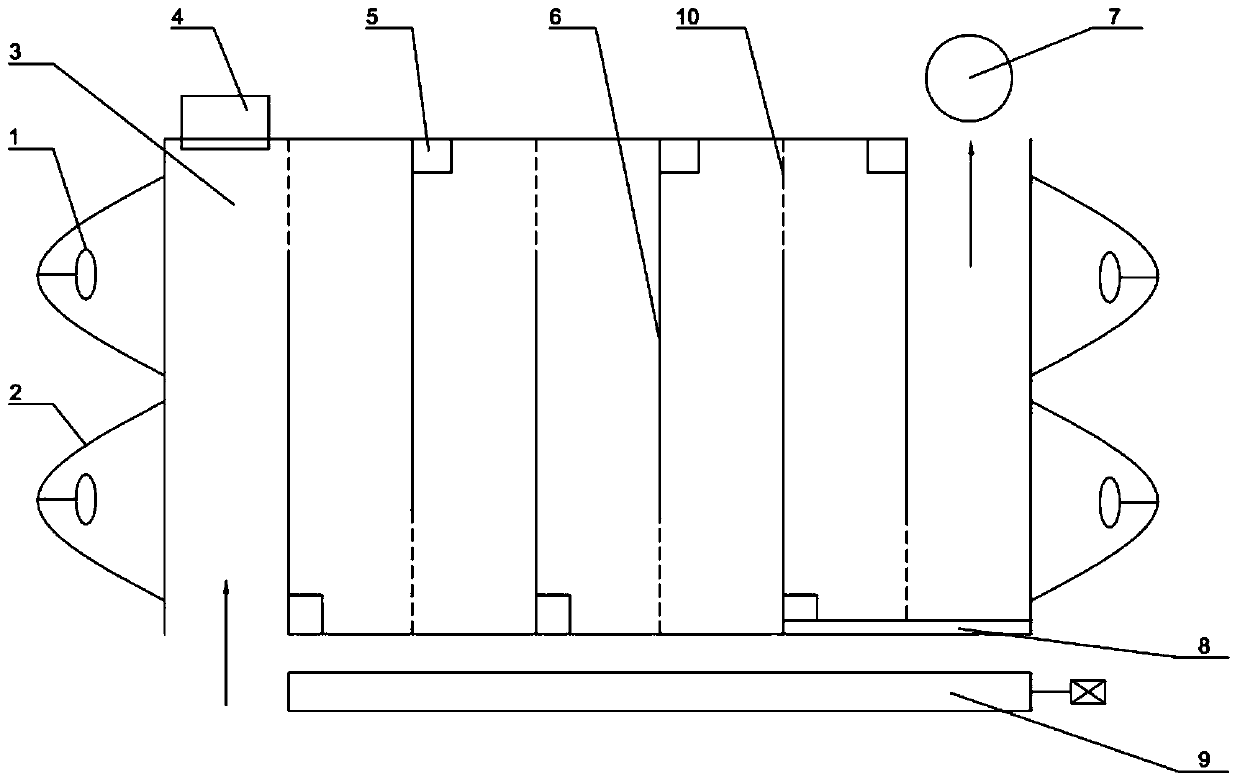

[0028] see figure 1 , the present embodiment includes a sound wave generator, a hollow coagulation chamber, an atomizer, a sound-permeable panel, an induced draft fan, and a filter screen. A plurality of sound-transmitting panels are arranged in parallel in the coagulation cabin, and each sound-transmitting panel One end is directly connected to the inner wall of the coagulation chamber, and the other end is connected to the opposite inner wall of the coagulation chamber through a filter screen. The two adjacent filter screens are respectively connected to the inner walls of the opposite sides. At least one sound wave generator is symmetrically installed, and the sound wave generator faces into the coagulation cabin, and the coagulation cabin is respectively provided with a smoke inlet and a smoke outlet at both ends of the channel formed along the sound-transmitting plate.

[0029] In order to improve the intensity of the sound field, this embodiment also includes a parabolic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com