Heat recovery system of multi-effect evaporation system and processing method thereof

A multi-effect evaporation and treatment method technology, applied in the system field of heat recovery and utilization, can solve the problems of inability to effectively utilize low-temperature heat sources, large consumption of fresh steam, and large equipment investment, so as to reduce subsequent processing costs and reduce fresh steam. consumption, the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

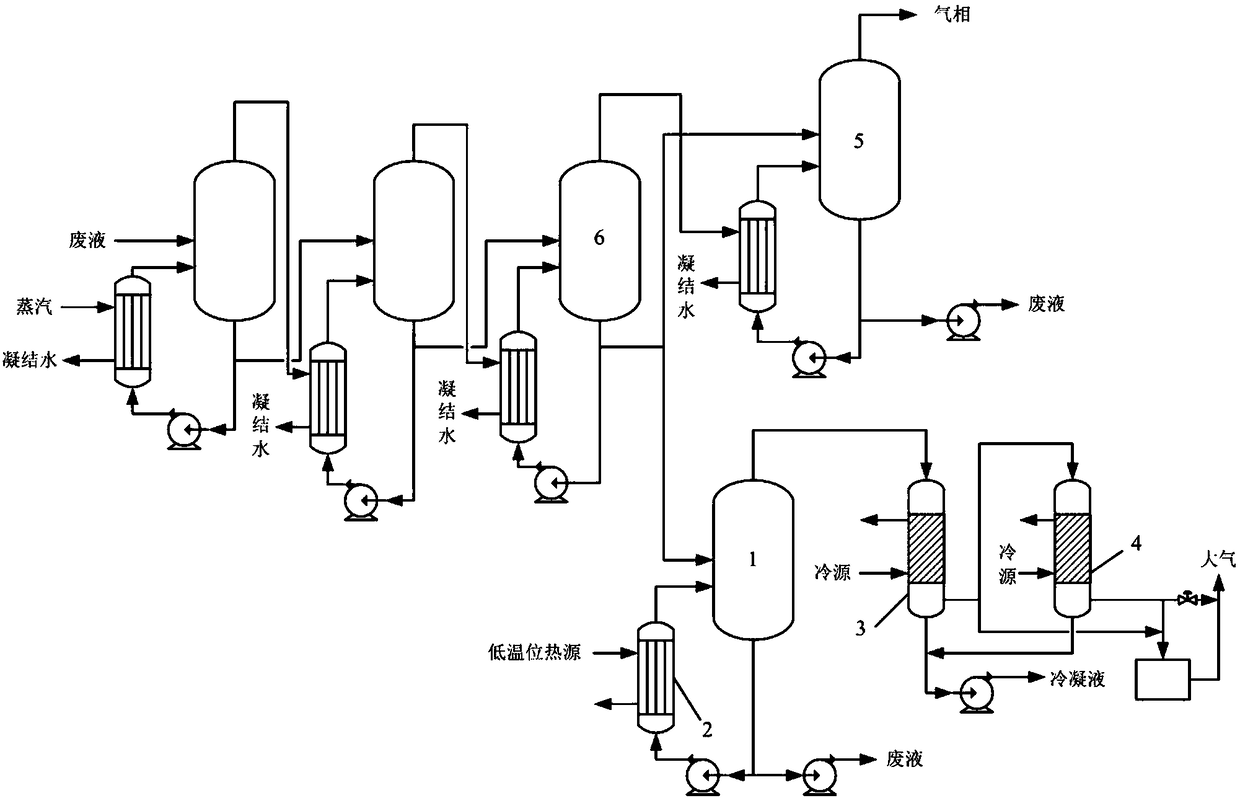

[0067] This embodiment provides a system for recovering and utilizing heat in a multi-effect evaporation system and its treatment method, such as figure 2 As shown, the system includes an evaporation device 1 connected in parallel with the final effect evaporation device 5 in the multi-effect evaporation system. The bottom of the evaporation device 1 is provided with a heating device 2, and the heat source of the heating device 2 is the temperature generated in a nearby device. It is a low-temperature heat source at 90°C to 130°C.

[0068] Among them, the multi-effect evaporation system is a four-effect evaporation system, and the liquid produced by the penultimate effect evaporator 6 of the four-effect evaporation system is divided into two paths, one path is sent to the final effect evaporator 5 in the four-effect evaporation system, and the other path is Send to evaporation device 1;

[0069] The heat supply device 2 is a reboiler. The liquid produced by the evaporator 1 ...

Embodiment 2

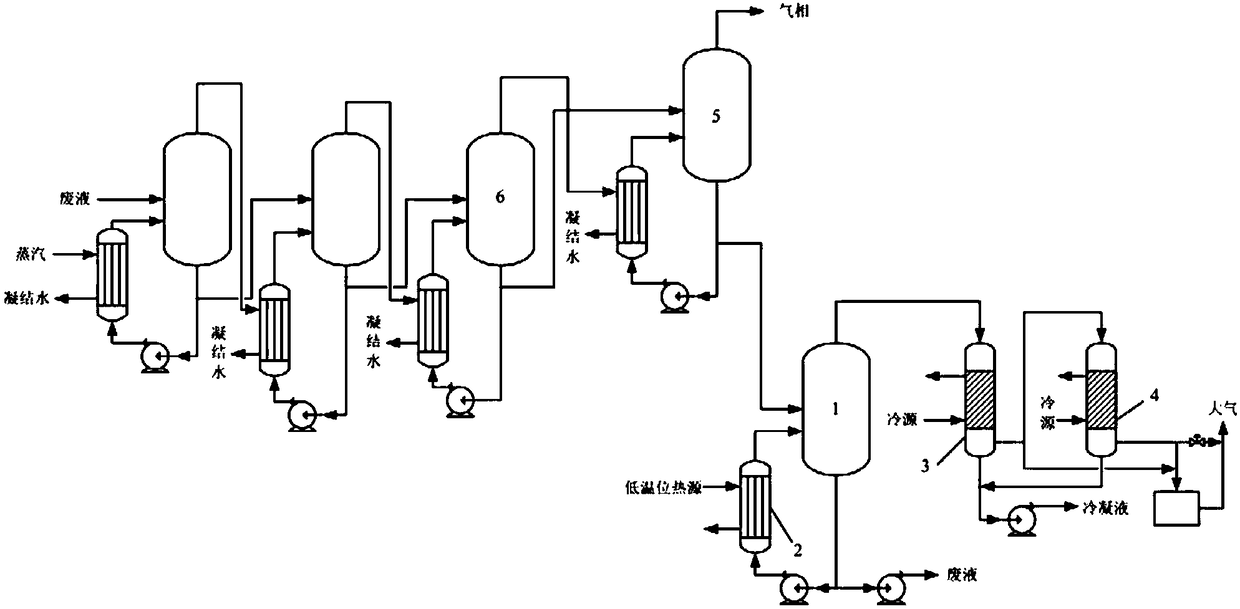

[0082] This embodiment provides a system for recovering and utilizing heat in a multi-effect evaporation system and its treatment method, such as image 3 As shown, the system includes an evaporation device 1 connected in series with the final effect evaporation device 5 in the multi-effect evaporation system. The bottom of the evaporation device 1 is provided with a heating device 2, and the heat source of the heating device 2 is the temperature generated in a nearby device. It is a low-temperature heat source at 90°C to 130°C.

[0083] Among them, the multi-effect evaporation system is a four-effect evaporation system, and the liquid produced by the final effect evaporation device 5 of the four-effect evaporation system is sent to the evaporation device 1;

[0084] The heat supply device 2 is a reboiler. The liquid produced by the evaporator 1 exchanges heat with the heat supply device 2 and returns to the evaporator 1. There is a Power transmission unit circulation pump; ...

Embodiment 3

[0090] This embodiment provides a system for recovering and utilizing heat in a multi-effect evaporation system and its treatment method. Its structure and method refer to Embodiment 1, the only difference is that the multi-effect evaporation system is a three-effect evaporation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com