A method for grinding-assisted self-infiltration synthesis of highly efficient catalytic degradation of methylene blue metal mesoporous silica

A mesoporous silica, catalytic degradation technology, applied in chemical instruments and methods, non-metallic elements, oxidized water/sewage treatment, etc., to achieve the effects of excellent adsorption/catalytic performance, fewer species, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

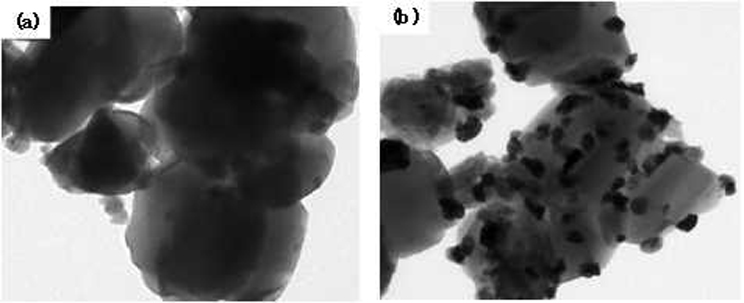

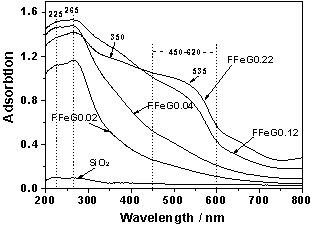

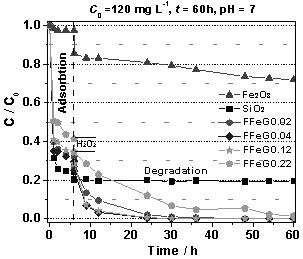

Image

Examples

Embodiment 1

[0032] S1. Dissolve 2.0g of triblock copolymer P123 as a template in 75g of water, stir until completely dissolved, add 2.41g of aluminum chloride hexahydrate, and place the mixture in a water bath at 35°C for 0.5h;

[0033] S2. Using tetraethyl orthosilicate as the silicon source, the addition amount is 4.16g, and stirred for 24h in a water bath at 35°C;

[0034] S3. Pour the mixed solution in S2 into an autoclave for hydrothermal aging at 100°C for 24 hours, filter, wash with deionized water, repeat twice, and dry naturally to obtain mesoporous silica containing a template;

[0035] S4. Weigh 0.6g of mesoporous silicon oxide prepared in step S3, add 0.0162g of anhydrous ferric chloride, grind and mix, add 2 drops of absolute ethanol dropwise during the grinding process, the grinding time is 35min, and then In the furnace, the temperature was first raised to 200°C at a rate of 6°C / min, and kept for 30 minutes, then raised to 550°C at a rate of 2°C / min, kept for 300 minutes, a...

Embodiment 2

[0040] S1. Dissolve 2.0g of triblock copolymer P123 as a template in 75g of water, stir until completely dissolved, add 2.41g of aluminum chloride hexahydrate, and place the mixture in a water bath at 35°C for 1 hour;

[0041] S2. Using tetraethyl orthosilicate as the silicon source, the addition amount is 4.16g, and stirred for 24h under the condition of 35°C water bath;

[0042] S3. Pour the mixed solution in S2 into a high-pressure reactor for hydrothermal aging at 100°C for 24 hours, filter, wash with deionized water, repeat 3 times, and dry naturally to obtain mesoporous silica containing a template;

[0043] S4. Weigh 0.6g of mesoporous silicon oxide prepared in step S3, add 0.0162g of anhydrous ferric chloride, grind and mix, add 3 drops of absolute ethanol dropwise during the grinding process, the grinding time is 35min, and then In the furnace, the temperature was first raised to 200°C at a rate of 6°C / min, kept for 30 minutes, then raised to 550°C at a rate of 2°C / mi...

Embodiment 3

[0049] S1. Dissolve 2.0g of triblock copolymer P123 as a template in 75g of water, stir until completely dissolved, add 2.41g of aluminum chloride hexahydrate, and place the mixture in a water bath at 35°C for 0.5h;

[0050] S2. Using tetraethyl orthosilicate as the silicon source, the addition amount is 4.16g, and stirred for 24h under the condition of 35°C water bath;

[0051] S3. Pour the mixed solution in S2 into an autoclave for hydrothermal aging at 100°C for 24 hours, filter, wash with deionized water, repeat twice, and dry naturally to obtain mesoporous silica containing a template;

[0052] S4. Weigh 0.6g of mesoporous silicon oxide prepared in step S3, add 0.0811g of anhydrous ferric chloride, grind and mix, add 3 drops of absolute ethanol dropwise during the grinding process, the grinding time is 28min, and then In the furnace, the temperature was first raised to 200°C at a rate of 6°C / min, kept for 30 minutes, then raised to 550°C at a rate of 2°C / min, kept for 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com