Cleaning device for sealing machine sealing heads

A cleaning device and packaging machine technology, applied in the cleaning method using tools, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of difficulty in improving production efficiency, scrapping batteries in batches, and long downtime of equipment, etc. , to achieve a high degree of automation, avoid manual cleaning, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

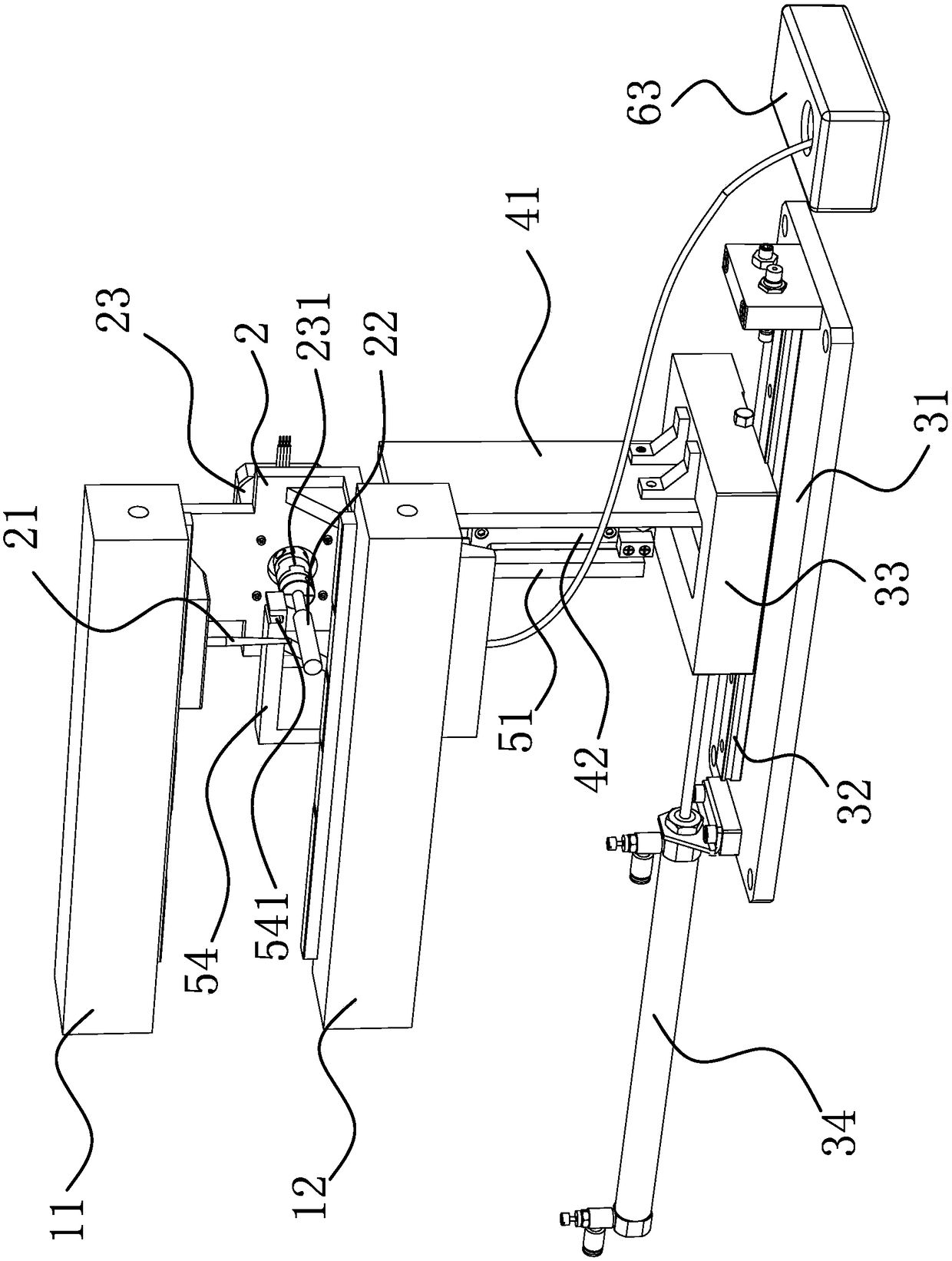

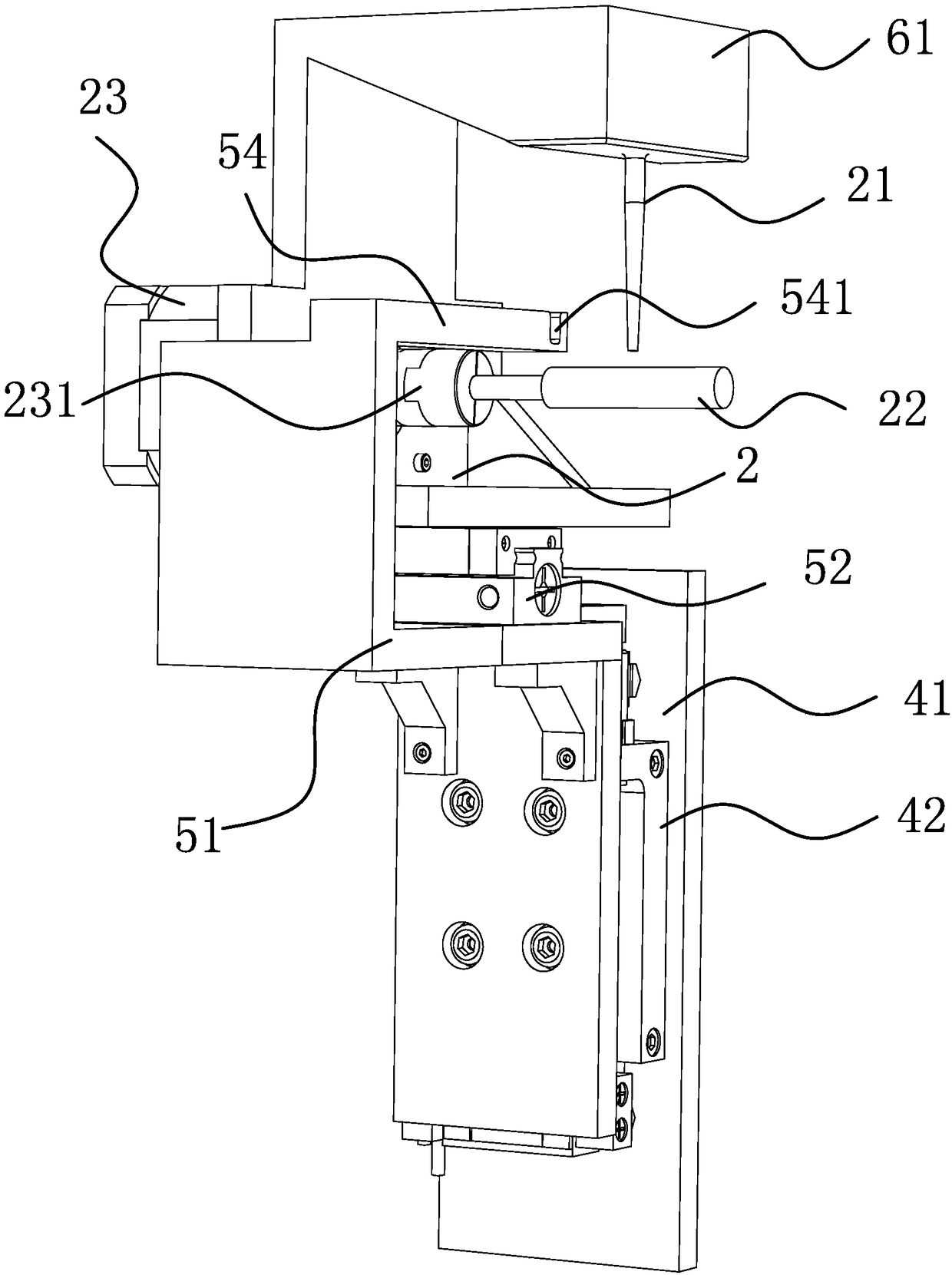

[0030] Such as figure 1 As shown, a cleaning device for the head of a packaging machine, the head includes an upper head 11 and a lower head 12, the upper head 11 and the lower head 12 are arranged in parallel and horizontally, the gap between the upper head 11 and the lower head 12 There is a gap between them to accommodate the battery to be packaged, and the two can pack the battery by approaching each other. The inner surfaces of the upper head 11 and the lower head 12 are sealed, and hot melt adhesive for packaging can flow out from the sealing positions of the upper head 11 and the lower head 12, and the hot melt adhesive is usually PP glue.

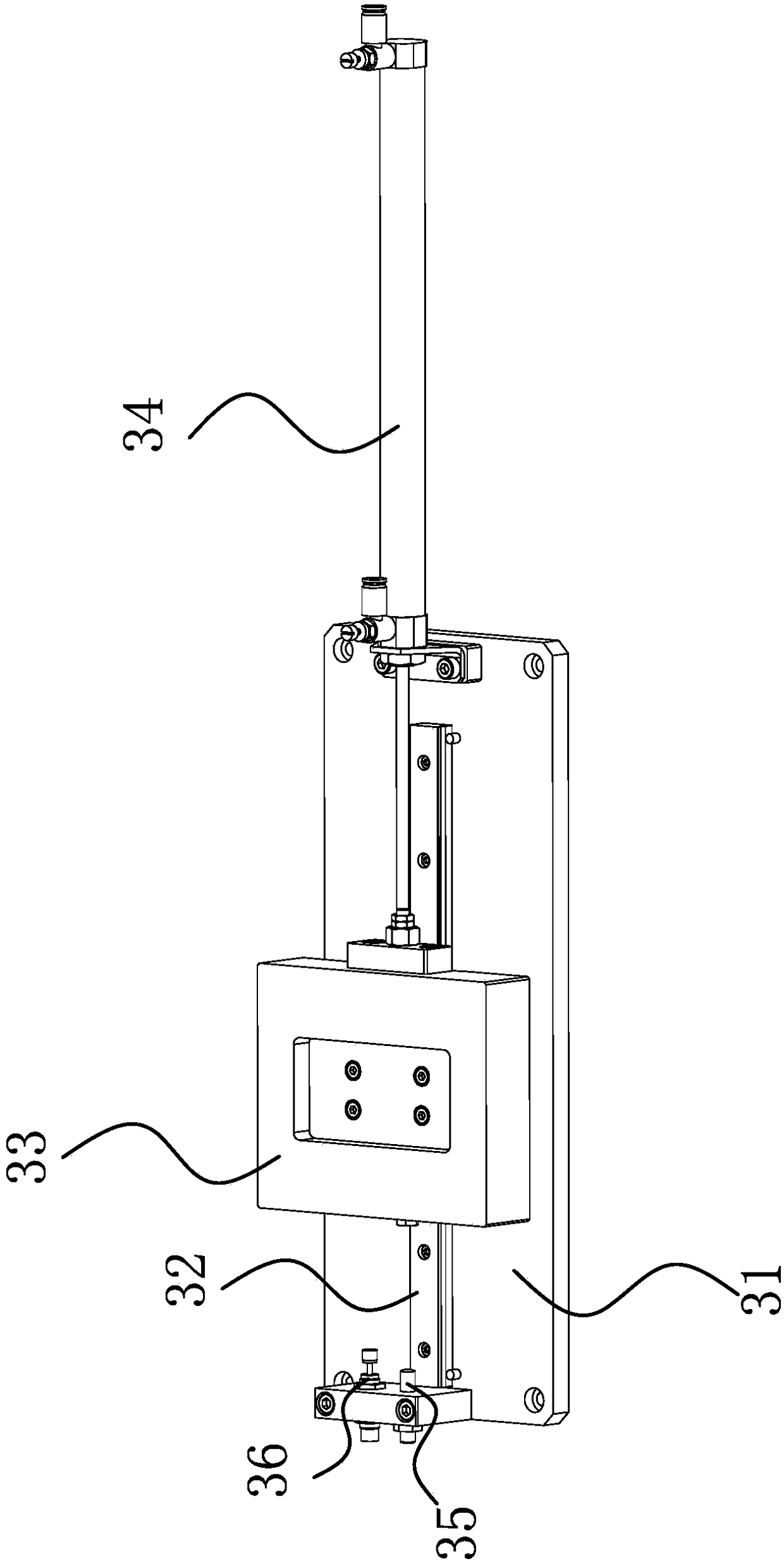

[0031] Such as figure 1 As shown, the cleaning device includes a bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com