Intelligent pipe dredging robot

A technology of intelligent pipelines and robots, applied in the directions of manipulators, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of not being able to operate for a long time, incomplete dredging, injury of operators, etc., and achieve flexible improvement of operation stroke and movement. , The effect of facilitating safe operation and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

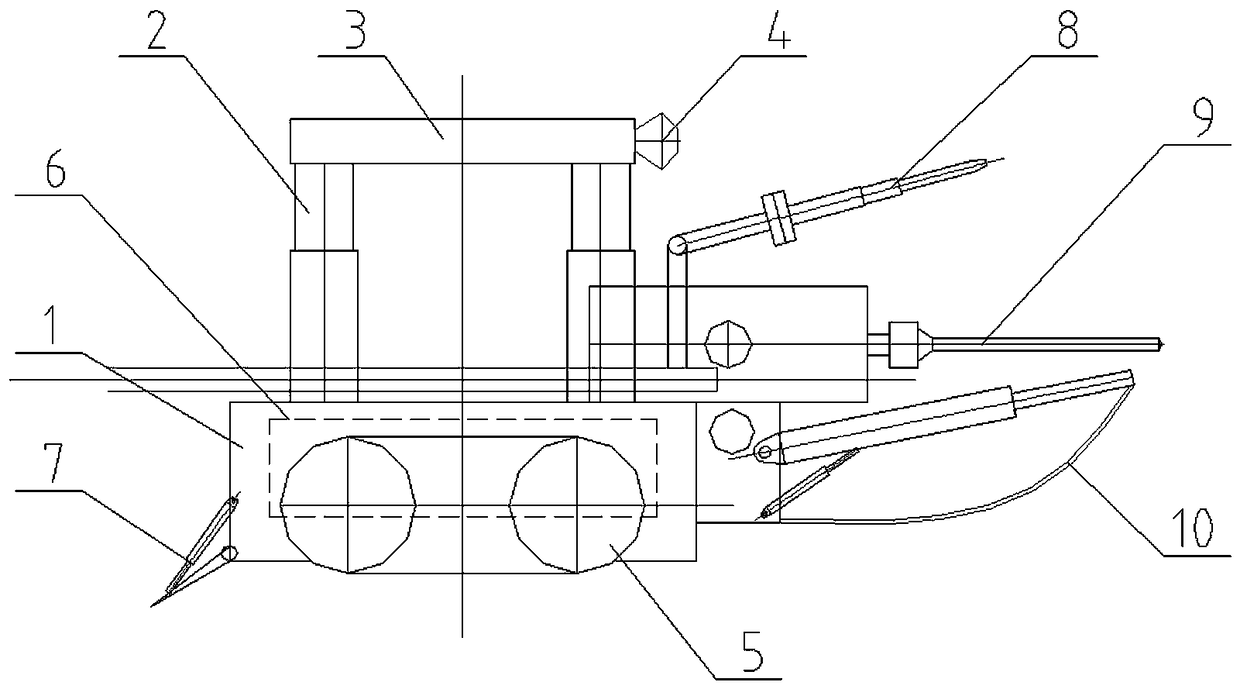

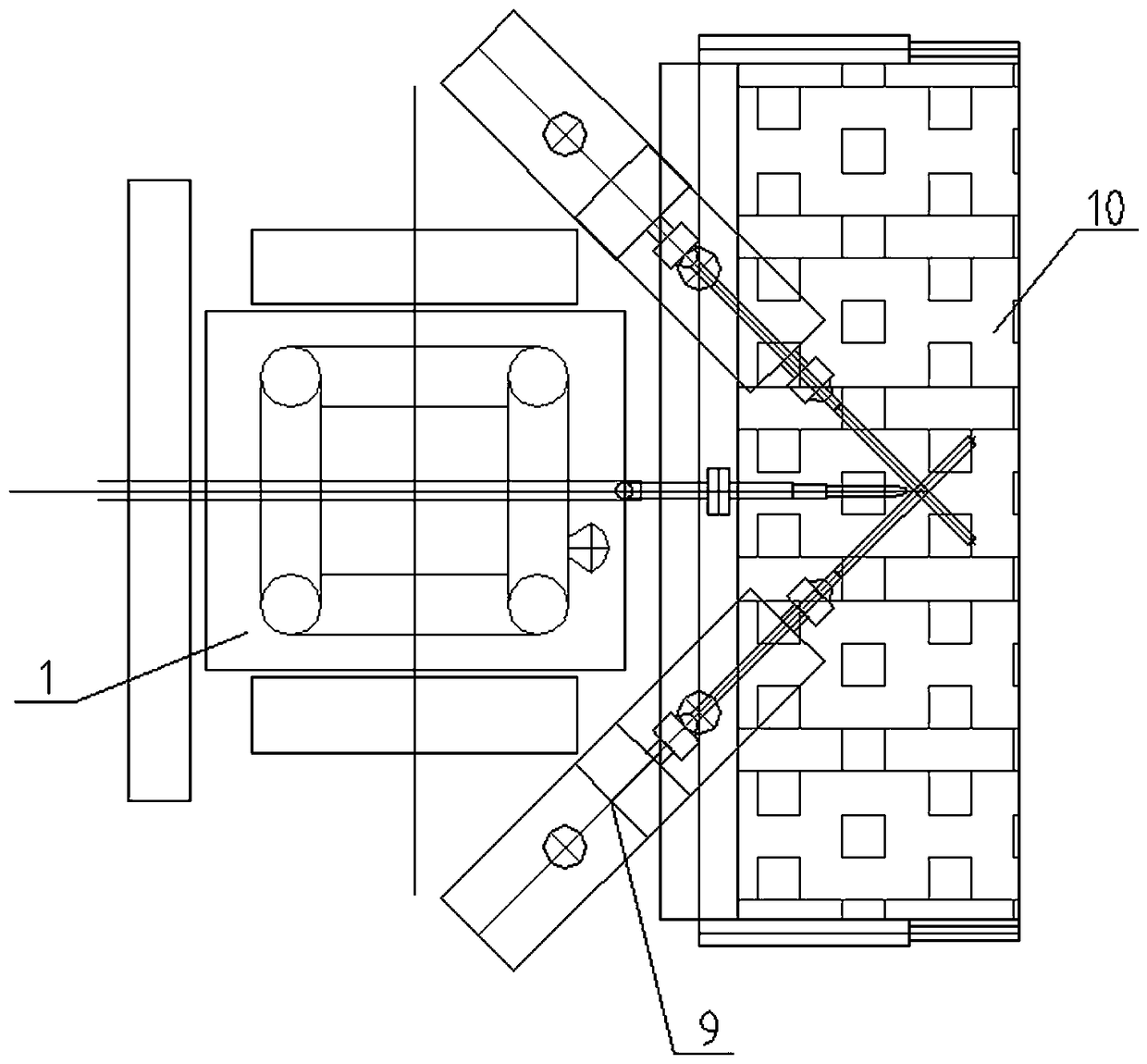

[0016] figure 1 , 2 As shown, an intelligent pipeline dredging robot includes a main frame 1, a main hydraulic rod 2, a top plate 3, a camera 4, a track wheel 5, a battery 6, a rear hydraulic rod 7, a high-pressure nozzle 8, a hydraulic splitter 9, and a sludge Collection box 10. The main frame 1 is equipped with a battery 6, the bottom of the main frame 1 is provided with a track wheel 5, and the main frame 1 is provided with a main hydraulic rod 2 for vertical lifting. The upper part of the main hydraulic rod is connected with a top plate 3 corresponding to the inner wall of the pipeline. On the main hydraulic rod or on the top plate or the front end of the main frame, the camera adopts wireless communication, and the main frame 1 is provided with a forward-facing high-pressure nozzle 8 and a plurality of forward-facing hydraulic splitters 9, and a connection is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com