Waste sand regeneration method reducing regeneration sand acid consumption value

A technology of acid consumption value and regenerated sand, which is used in the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc., which can solve the problem that secondary pollution cannot be effectively controlled and increase the cost of regeneration equipment. , reduce the acid consumption value research and elaboration and other issues, to achieve the effect of good technical feasibility and applicability, compact and reasonable process structure, reducing demand and waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

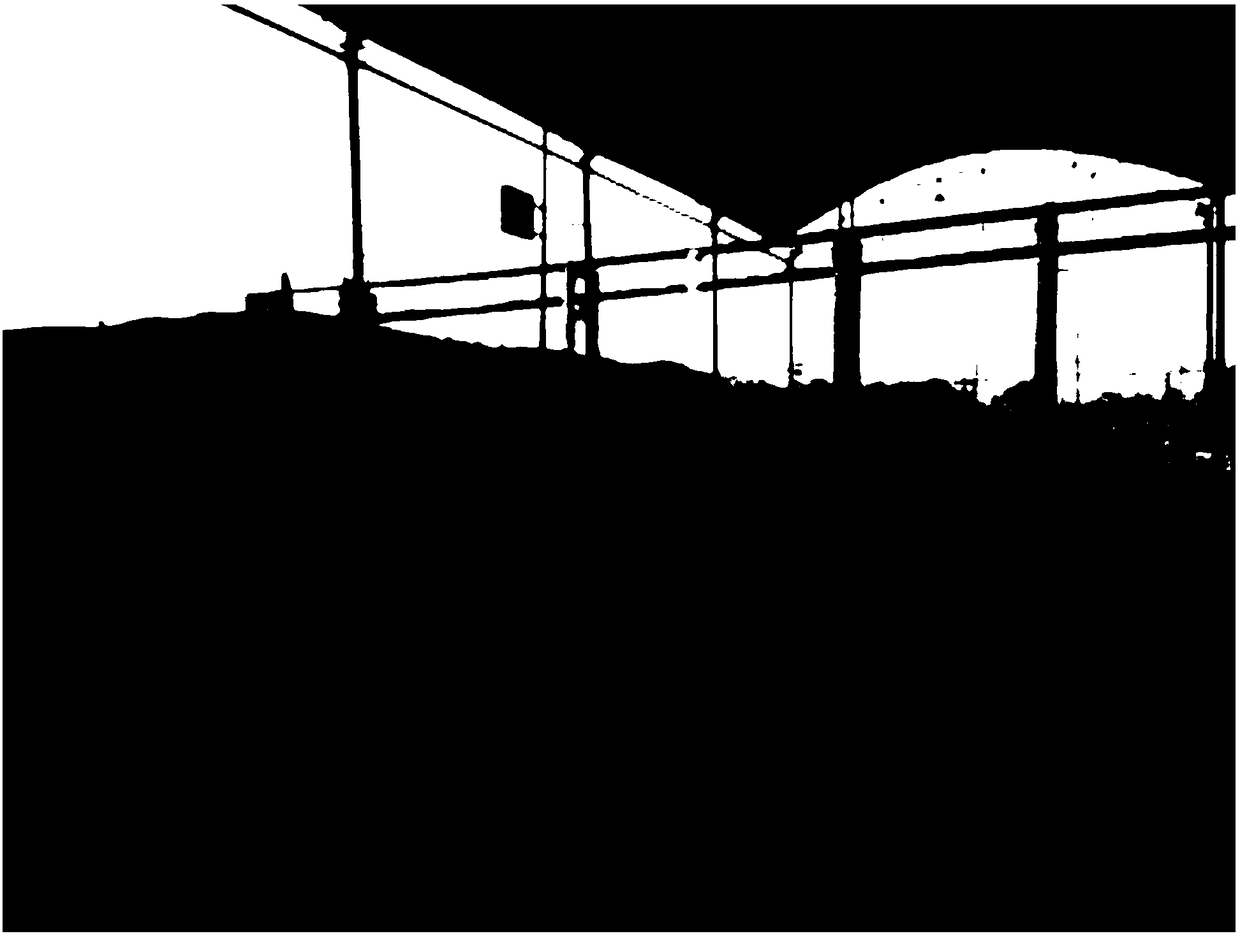

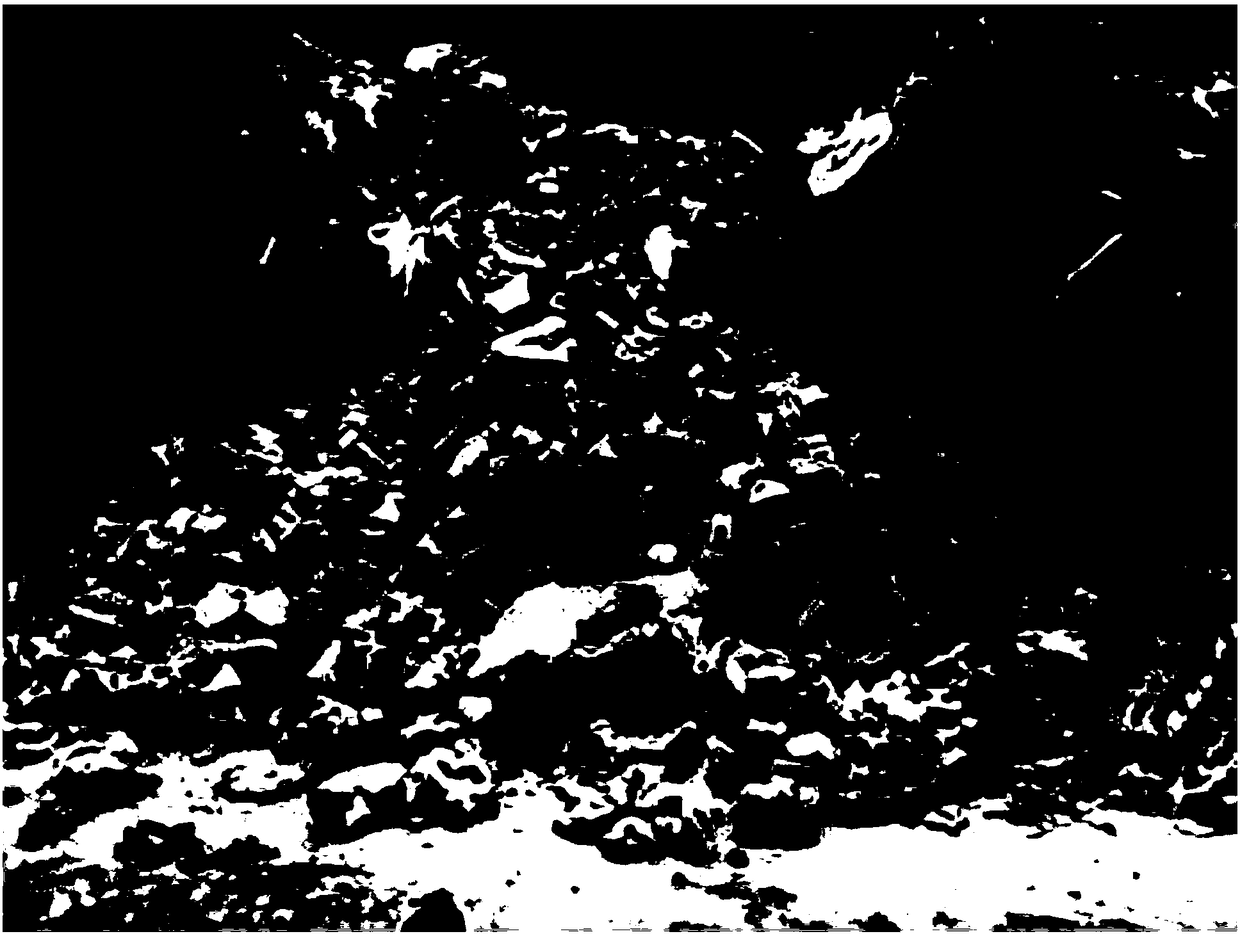

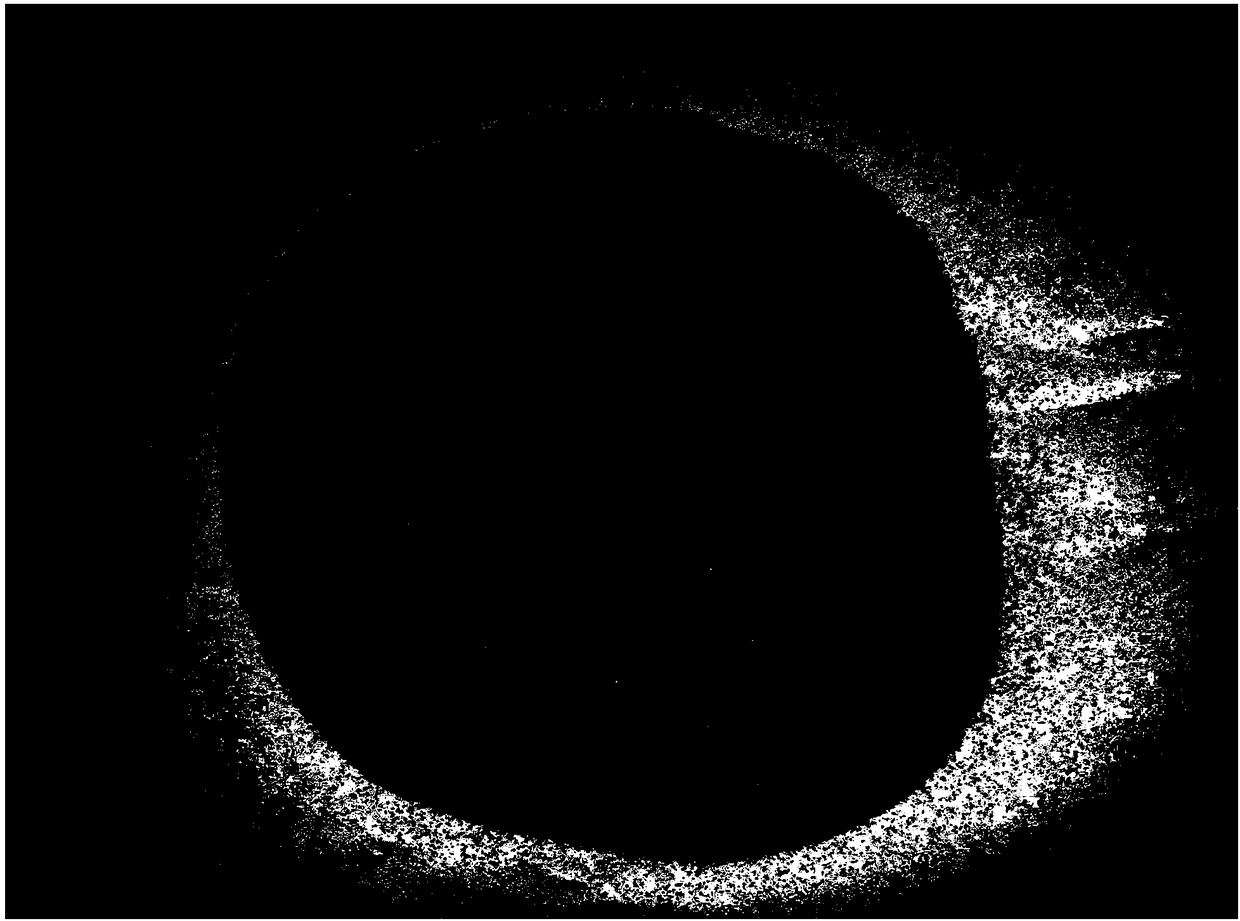

Image

Examples

Embodiment 1

[0031] The waste sand regeneration method for reducing the acid consumption value of the regenerated sand in this embodiment is carried out in the following steps:

[0032] (1) Waste sand crushing: the waste sand is crushed into fine sand, which is convenient for entering the roasting furnace; the fine sand mesh number is 10-20 mesh;

[0033] (2) Roasting: Put the fine sand in a roasting furnace, first roast it at 340°C for 60 minutes to remove the inert film on the surface of the inorganic coated sand, and then roast it at 650°C for 60 minutes to completely burn out the organic matter in the waste sand;

[0034] (3) Wet mixing and regeneration: The fine sand after step (2) is stirred in a wet mixing tank containing a dilute acid solution for 30 minutes. On the one hand, it cools the sand and reduces the alkalinity in the sand. Material neutralization treatment; then the mixture of fine sand and dilute acid solution enters the sand-water separator for sand-water separation, the separ...

Embodiment 2

[0039] The waste sand regeneration method for reducing the acid consumption value of the regenerated sand in this embodiment is carried out in the following steps:

[0040] (1) Waste sand crushing: the waste sand is crushed into fine sand, which is convenient for entering the roasting furnace; the fine sand mesh number is 10-20 mesh;

[0041] (2) Roasting: Place the fine sand in a roasting furnace, first roast at 360°C for 50 minutes to remove the inert film on the surface of the inorganic coated sand, and then roast at 640°C for 60 minutes to completely burn out the organic matter in the waste sand;

[0042] (3) Wet mixing and regeneration: The fine sand after step (2) is stirred in a wet mixing tank containing a dilute acid solution. The mixing time is 25 minutes. On the one hand, the temperature of the sand is cooled, and the alkalinity in the sand is reduced. Material neutralization treatment; then the mixture of fine sand and dilute acid solution enters the sand-water separator ...

Embodiment 3

[0047] The waste sand regeneration method for reducing the acid consumption value of the regenerated sand in this embodiment is carried out in the following steps:

[0048] (1) Waste sand crushing: the waste sand is crushed into fine sand, which is convenient for entering the roasting furnace; the fine sand mesh number is 10-20 mesh;

[0049] (2) Roasting: Place the fine sand in a roasting furnace, first roast at 350°C for 70 minutes to remove the inert film on the surface of the inorganic coated sand, and then roast at 660°C for 70 minutes to completely burn out the organic matter in the waste sand;

[0050] (3) Wet mixing and regeneration: The fine sand after step (2) is stirred in a wet mixing tank containing a dilute acid solution for 30 minutes. On the one hand, it cools the sand and reduces the alkalinity in the sand. Material neutralization treatment; then the mixture of fine sand and dilute acid solution enters the sand-water separator for sand-water separation, the separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com