Formula of tobacco casing flavor and application of tobacco casing flavor to improvement of sensory quality of upper leaf

A technology for adding flavors and tobacco extracts, applied in the field of tobacco production, can solve problems such as insufficient formulation technology of flavorings, and achieve the effects of expanding the source of production raw materials, improving economic value, and making the smoke delicate and soft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

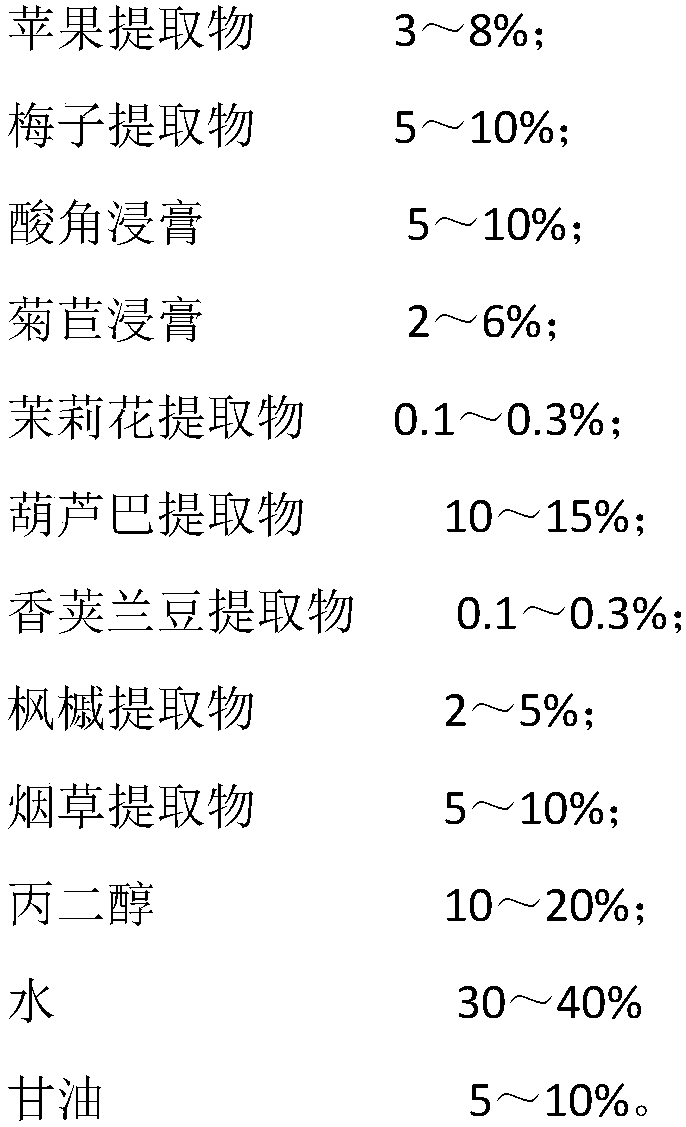

[0021] The present embodiment provides a tobacco flavoring essence formula (feed liquid) for improving the sensory quality of upper tobacco leaves, which consists of the following components in terms of mass percentage:

[0022]

[0023] The preparation method can be referred to as follows: first add auxiliary materials water, propylene glycol, then add apple extract, plum extract, tamarind extract, chicory extract, jasmine flower extract, fenugreek extract, vanilla bean extract, maple acer Extract and tobacco extract, add glycerin at the end, ideally mix at 25-35°C, store for 24 hours after mixing.

Embodiment 2

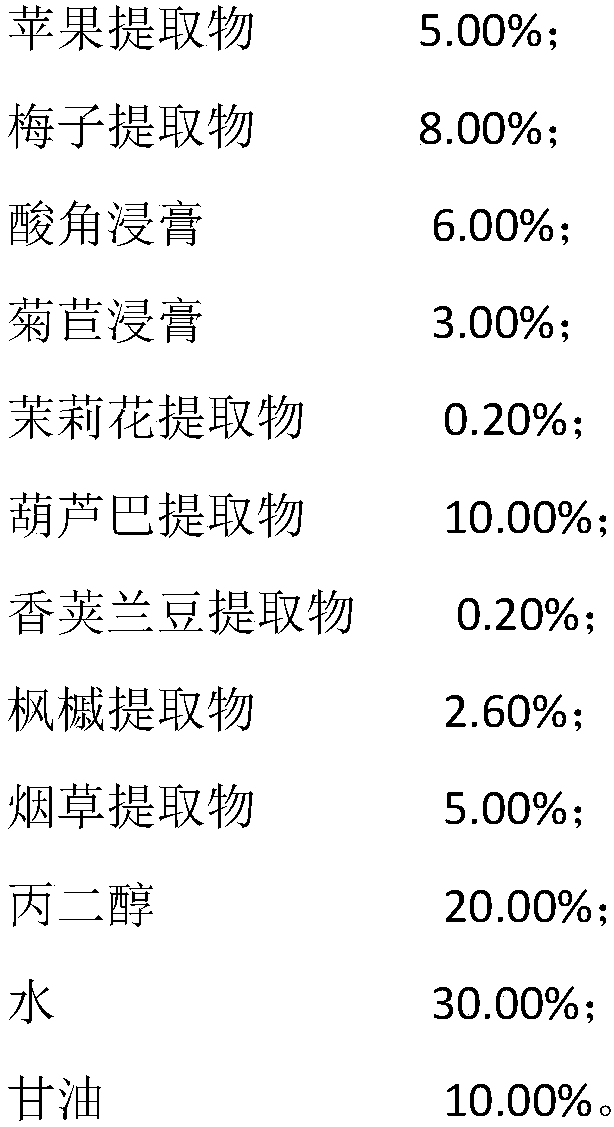

[0025] The present embodiment provides a tobacco flavoring essence formula (feed liquid) for improving the sensory quality of upper tobacco leaves, which consists of the following components in terms of mass percentage:

[0026]

[0027]

[0028] The preparation method can be referred to as follows: first add auxiliary materials water, propylene glycol, then add apple extract, plum extract, tamarind extract, chicory extract, jasmine flower extract, fenugreek extract, vanilla bean extract, maple acer Extract and tobacco extract, add glycerin at the end, ideally mix at 25-35°C, store for 24 hours after mixing.

Embodiment 3

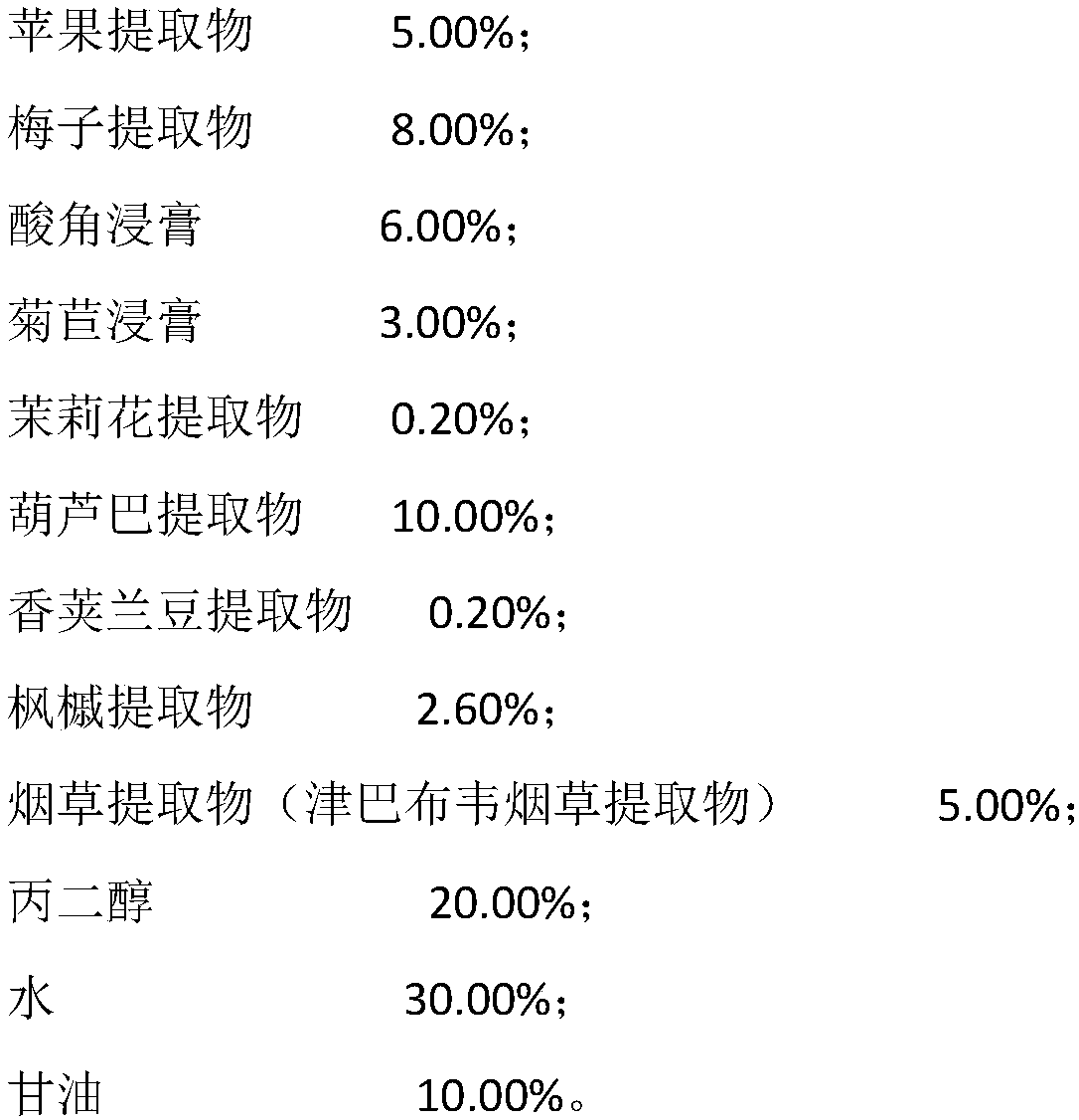

[0030] The present embodiment provides a tobacco flavoring essence formula (feed liquid) for improving the sensory quality of upper tobacco leaves, which consists of the following components in terms of mass percentage:

[0031]

[0032] The preparation method can be referred to as follows: first add auxiliary materials water, propylene glycol, then add apple extract, plum extract, tamarind extract, chicory extract, jasmine flower extract, fenugreek extract, vanilla bean extract, maple acer Extract and tobacco extract, add glycerin at the end, ideally mix at 25-35°C, store for 24 hours after mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com