A prefabricated underground diaphragm wall insertion device

An underground continuous wall and inserting equipment technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem that the ground connecting wall cannot fully meet the urban construction and other problems, achieve low noise, ensure construction quality, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

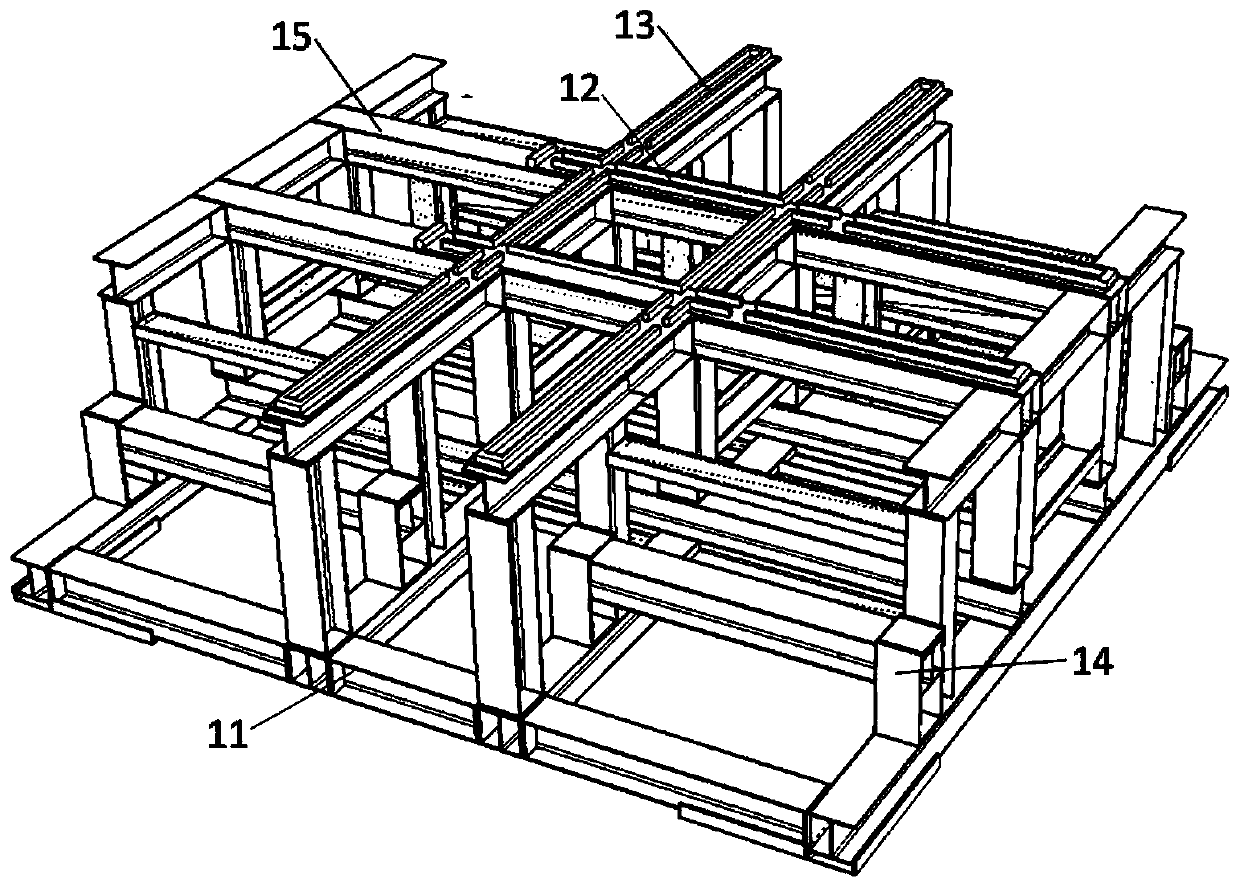

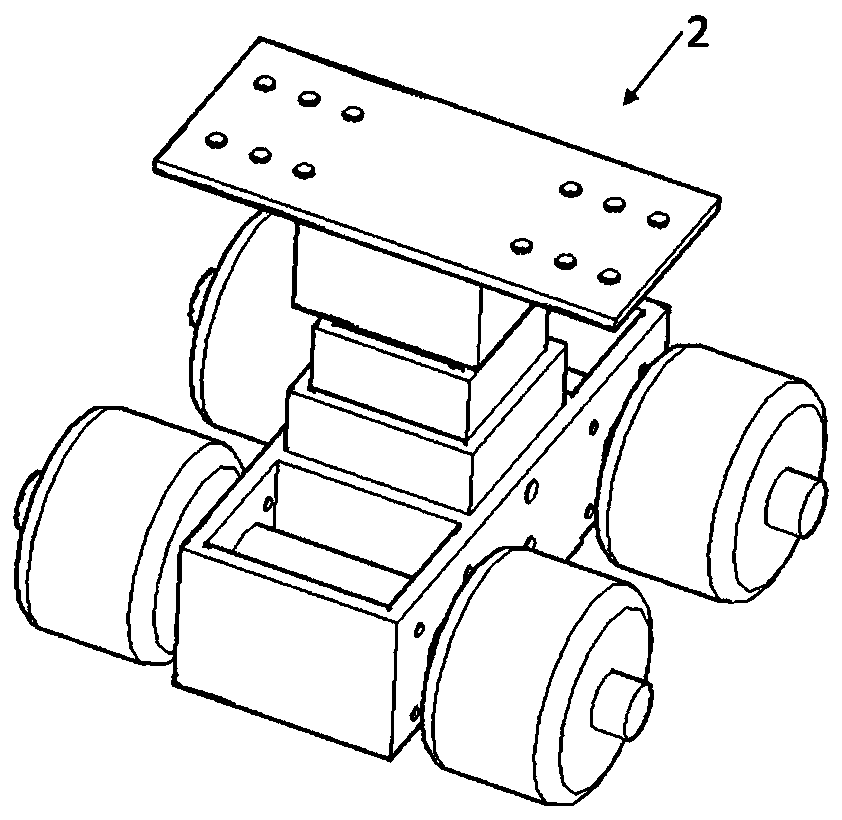

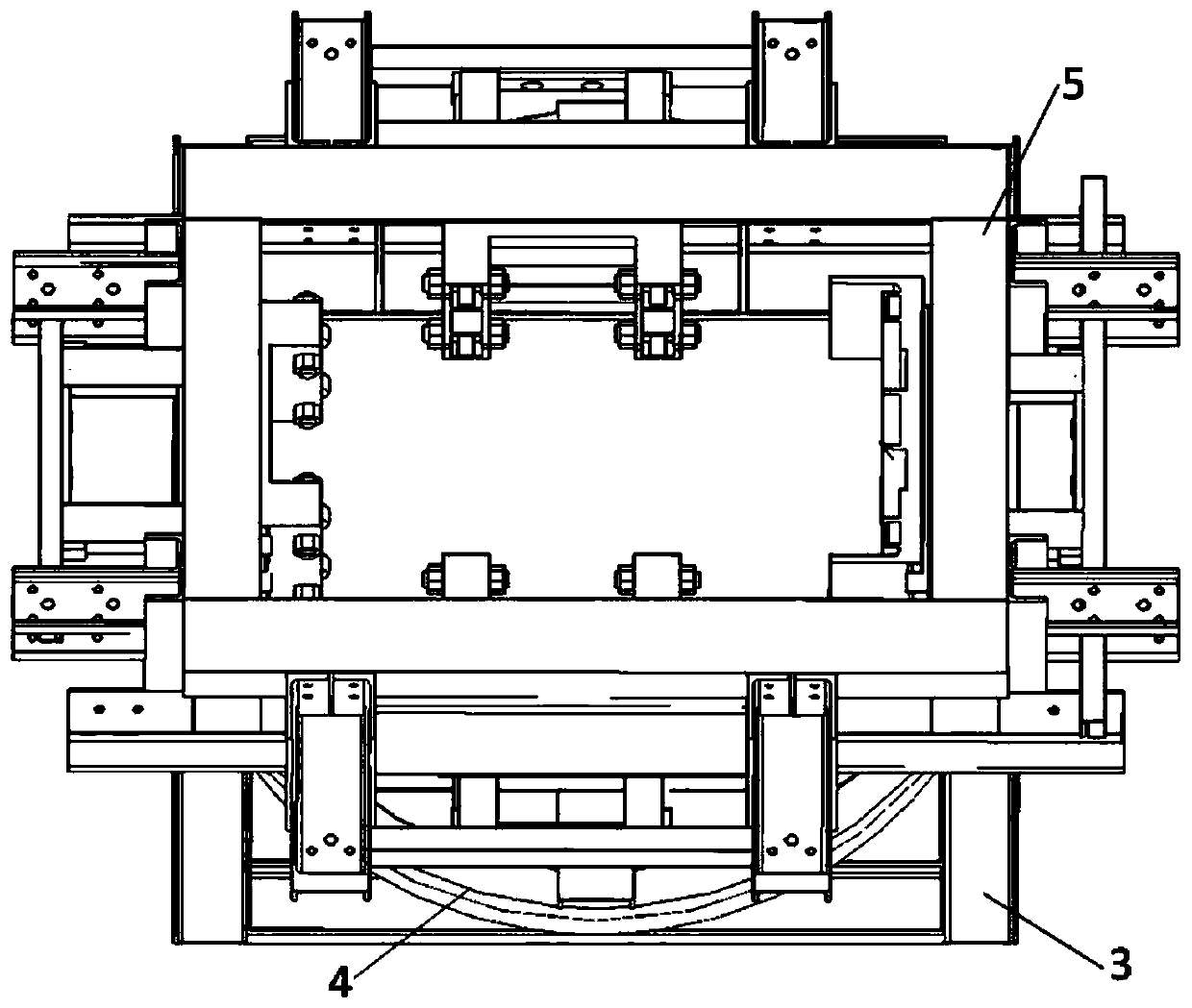

[0050] Such as Figure 1~9 As shown, a prefabricated underground continuous wall insertion device includes a skeleton base 1, the lower end of the skeleton base 1 is provided with a mobile steering device 2, and the upper end is provided with a sliding sliding adjustment frame 3, and the upper end of the sliding adjustment frame 3 is provided with There is a turning guide ring 4, the turning guide ring 4 is provided with a turning frame 5 that rotates along the turning guiding ring 4, the turning frame 5 is provided with a locator 6 for inserting into the wall, and the skeleton base 1 is also provided with a The pressurizing member 7 for pressurized connection to the wall.

[0051] The skeleton base 1 includes a bottom frame 11, on which a well-shaped supporting steel beam is arranged, and on the supporting steel beam, No. A No. I installation beam 14 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com