Sound-insulation and heat-insulation wood-plastic integrated frame-shear wooden wall

An integrated frame and wood-plastic technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of low environmental efficiency of building maintenance structures, poor sound insulation and heat insulation, and low market acceptance, so as to reduce material consumption and labor. Improved productivity and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

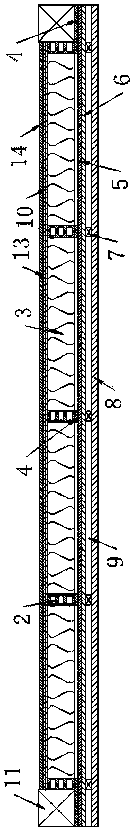

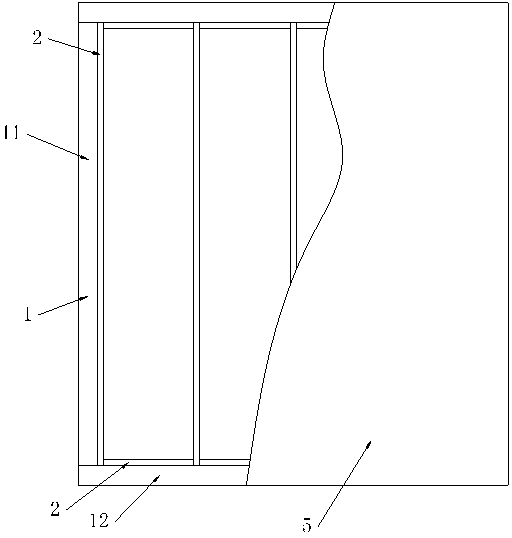

[0024] see figure 1 , 2 The shown sound-insulation and heat-insulation wood-plastic integrated frame shearing wood wall includes a cuboid-shaped glued-laminated wood frame 1 connected by two left and right glued-laminated wood columns 11 and two upper and lower glued-wood beams 12, and multiple Wood-plastic wall stud columns 2 with an interval of 600 mm, wherein the two wood-plastic wall stud columns 2 on the left and right sides are respectively adjacent to two glued wood columns 11 .

[0025] The cross-sectional size of the glulam columns and glulam beams is 120*120mm, and the glulam species that make up the glulam columns and glulam beams are SPF spruce-pine-fir, and the tree species grade is NO.1 (Canada NLGA visual classification) above. The wood-plastic wall stud column 2 is made of PE wood-plastic, and its cross-sectional size is 40*90mm.

[0026] The outer surface of the glulam frame facing the outside of the wall is flush with the outer surface of the wood-plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com