Heat pump air conditioning system provided with flat tube plate-fin type heat-source tower and working method of system

A heat source tower heat pump and air-conditioning system technology, applied in air-conditioning systems, heating methods, tubular elements, etc., can solve the problems of outdoor evaporator frosting, great influence of temperature and humidity changes, and reduce heat transfer performance, etc., to improve refrigeration capacity , improve system performance, improve the effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

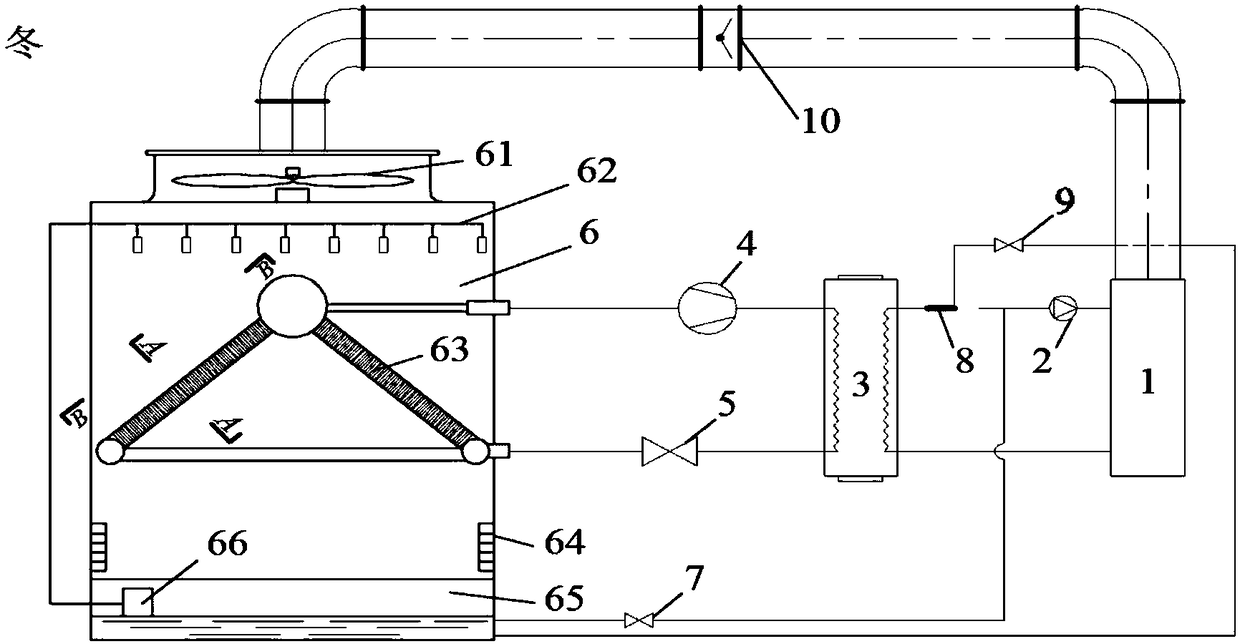

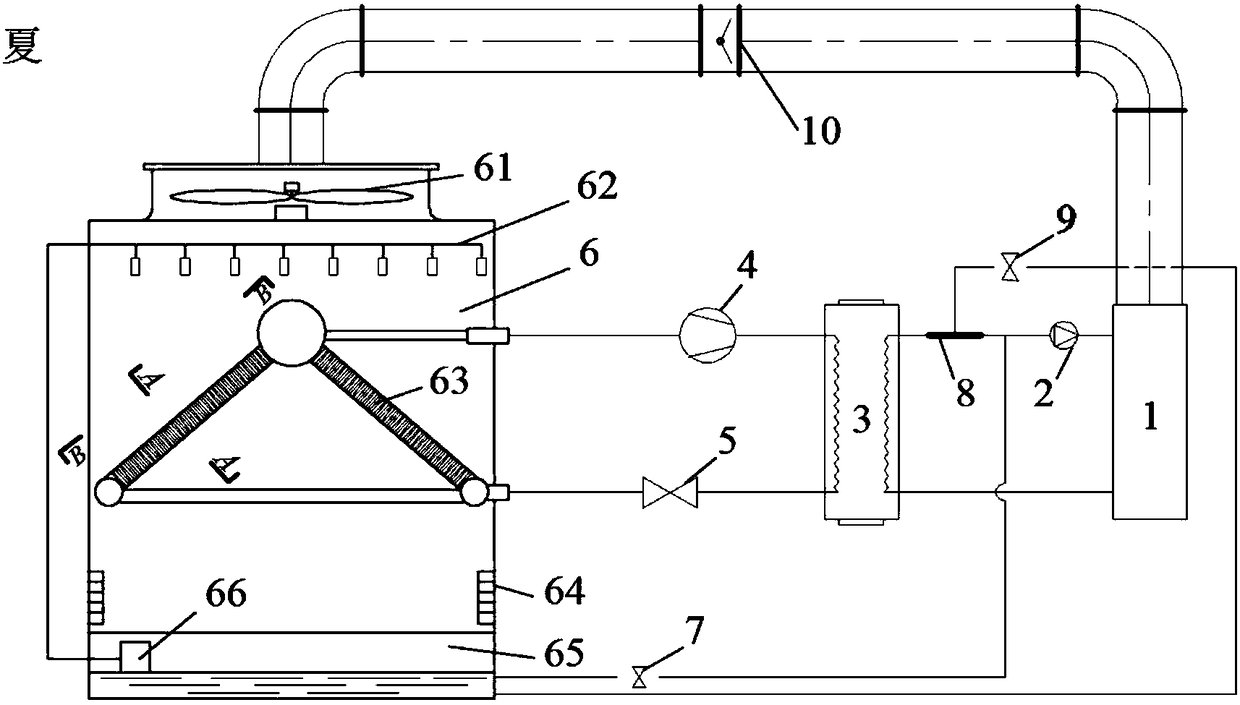

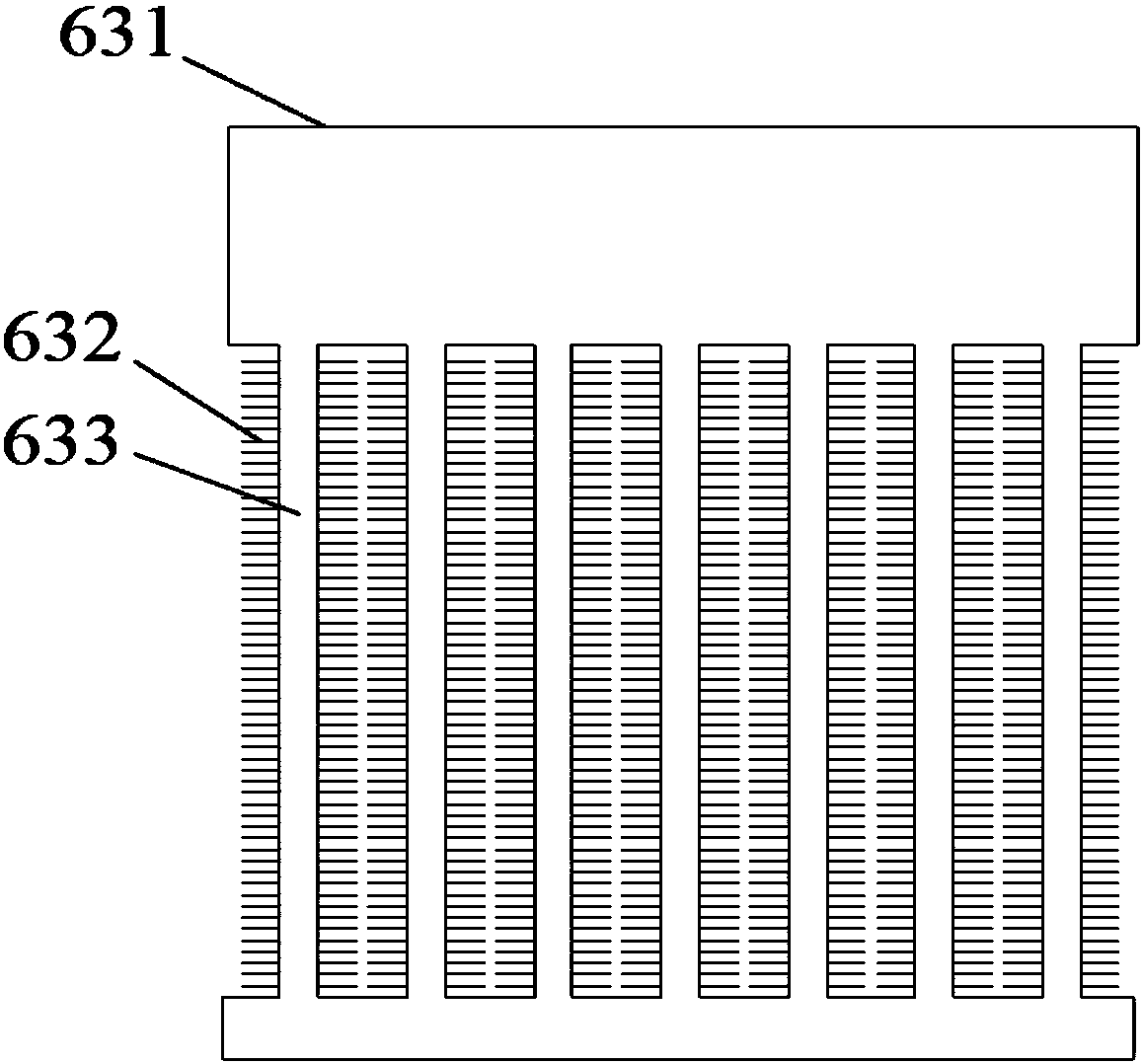

[0029] refer to figure 1 and figure 2 , the flat tube-plate-fin heat source tower heat pump air-conditioning system of the present invention comprises an oval flat tube-plate-fin heat source tower 6, an air conditioner 1, a first water pump 66, an evaporator 3, a reversing valve 8, and a first check valve 9. The second water pump 2 and the second check valve 7; the elliptical flat tube-plate-fin heat source tower 6 includes a tower body, and the tower body is sequentially provided with a spray device 62 and an elliptical flat tube-plate-fin heat exchanger from top to bottom. 63 and solution pool 65, the side of tower body is provided with air inlet 64, and the top of tower body is provided with the air outlet with blower fan 61, and the air outlet at tower body top is connected with the air inlet 64 of air conditioner 1, and the first water pump The inlet of 66 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com