High-temperature triaxial porosity and permeability testing device and method

A test device, high temperature technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., to achieve the effect of convenient repair and maintenance, simple operation and intensive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

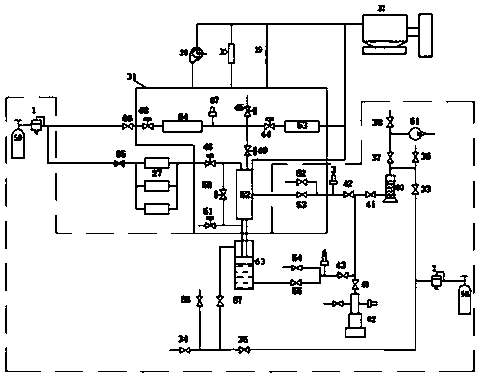

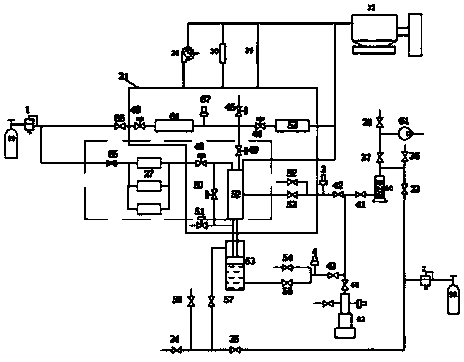

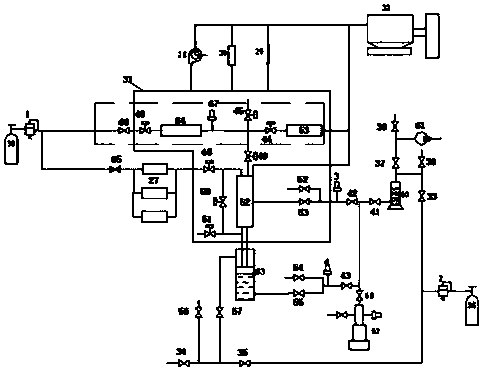

Image

Examples

Embodiment 1

[0060] Embodiment 1: the steps of the present invention when measuring porosity are as follows:

[0061] (1) Turn on the equipment "porosity measurement" and turn off "permeability measurement";

[0062] (2) connect each part by the porosity flow process, open the porosity software on the computer 32;

[0063] (3) Click System Settings, open the standard volume setting, enter the standard volume of 1 / 8, 3 / 8, 4 / 8, 8 / 8 standard block and click OK;

[0064] (4) Click on the basic parameters in the computer, and input parameters such as well number, well section, horizon, distance from the top, etc. Click on the sample information to input the diameter, length and other parameters of the core material;

[0065] (5) Click on the porosity measurement experiment to open the standard volume inspection interface;

[0066] (6) Ensure that all valves in the porosity measurement process are closed;

[0067] (7) Open particle volume holder, and valve 12 (44), valve 13 (45), pack all st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com