Open charging machine

A charging machine and an open technology, applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve the problems of high energy consumption, heavy overall weight, and slow heat dissipation of trains, and achieve compact structure, meet weight reduction, and reduce volume effect with weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

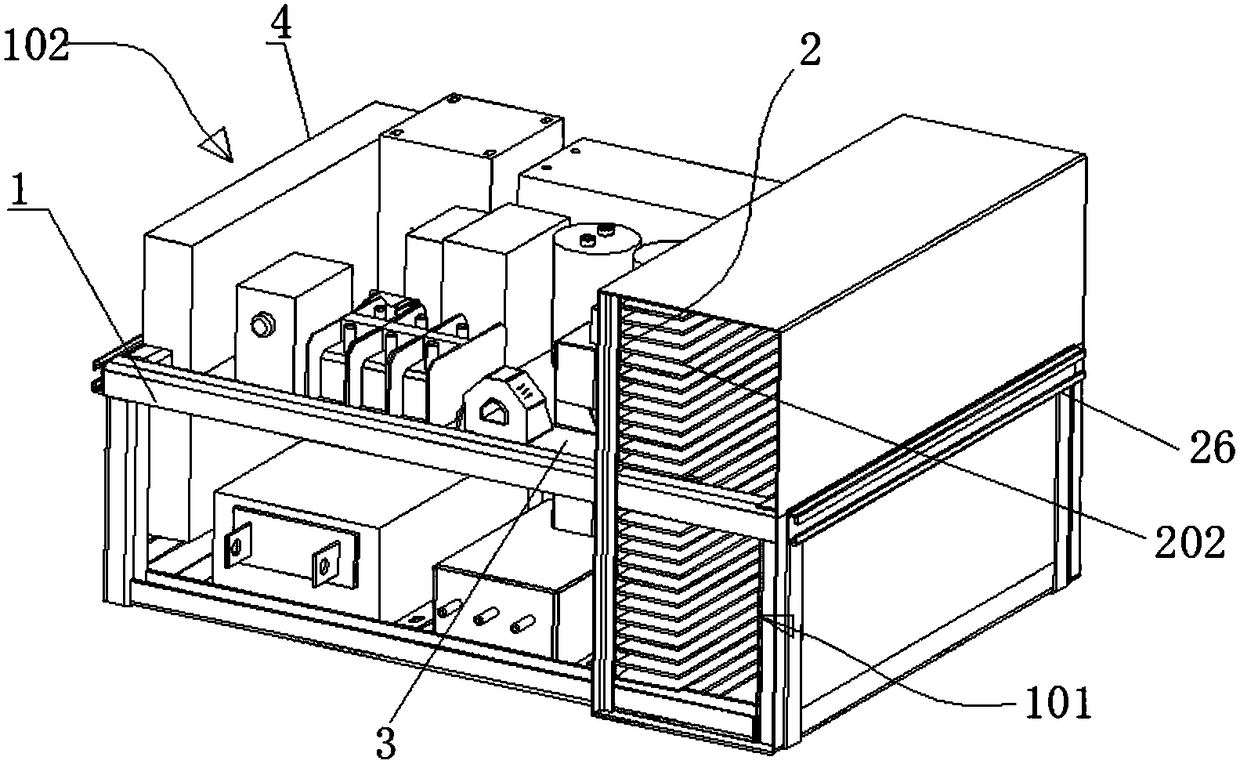

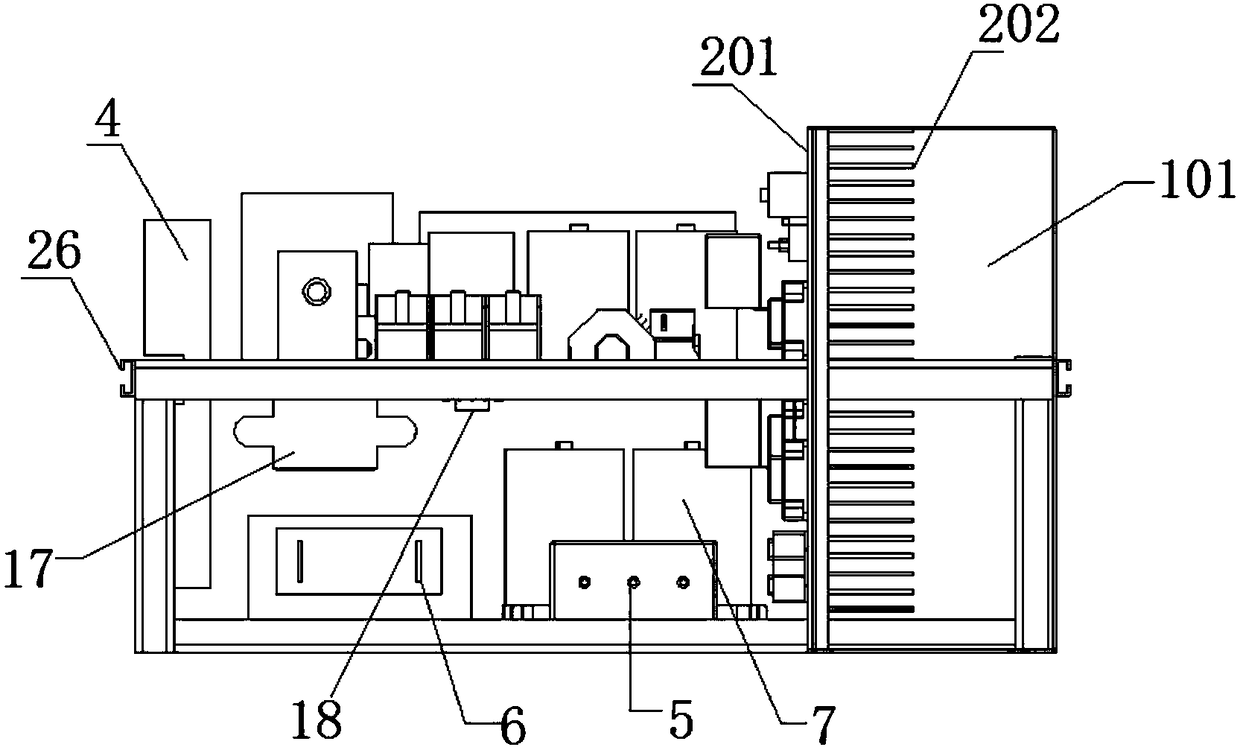

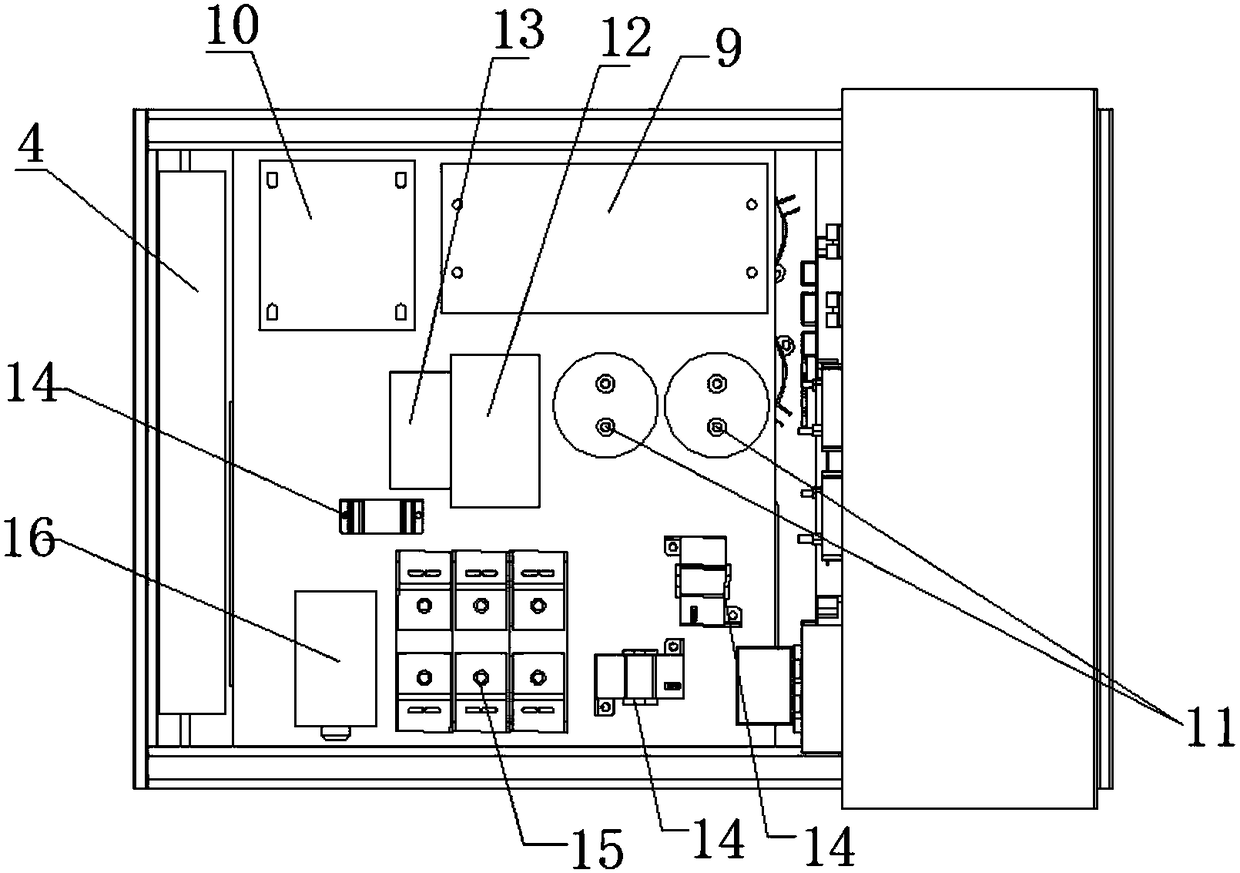

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, an open charger includes a mounting frame 1 and a radiator 2, and the radiator divides the mounting frame into two parts, a cooling air duct 101 and a device mounting area 102, and the radiator is mainly composed of a mounting surface 201 and a plurality of cooling fins 202 extending from the mounting surface, the mounting surface faces the device mounting area, the cooling fins extend into the cooling air duct, and the cooling air duct consists of several housings Surrounded by the installation surface of the radiator, and communicated from one side of the radiator to the other side; among the several devices that make up the charging circuit of the charger, the componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com