Intelligent PFC constant-current drive power circuit and control method

A technology of constant current drive and power supply circuit, applied in the field of intelligent PFC constant current drive power supply circuit and control, can solve the problems of unpredictable constant current, troublesome, fragile switch in the later stage, and achieve the effect of preventing burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

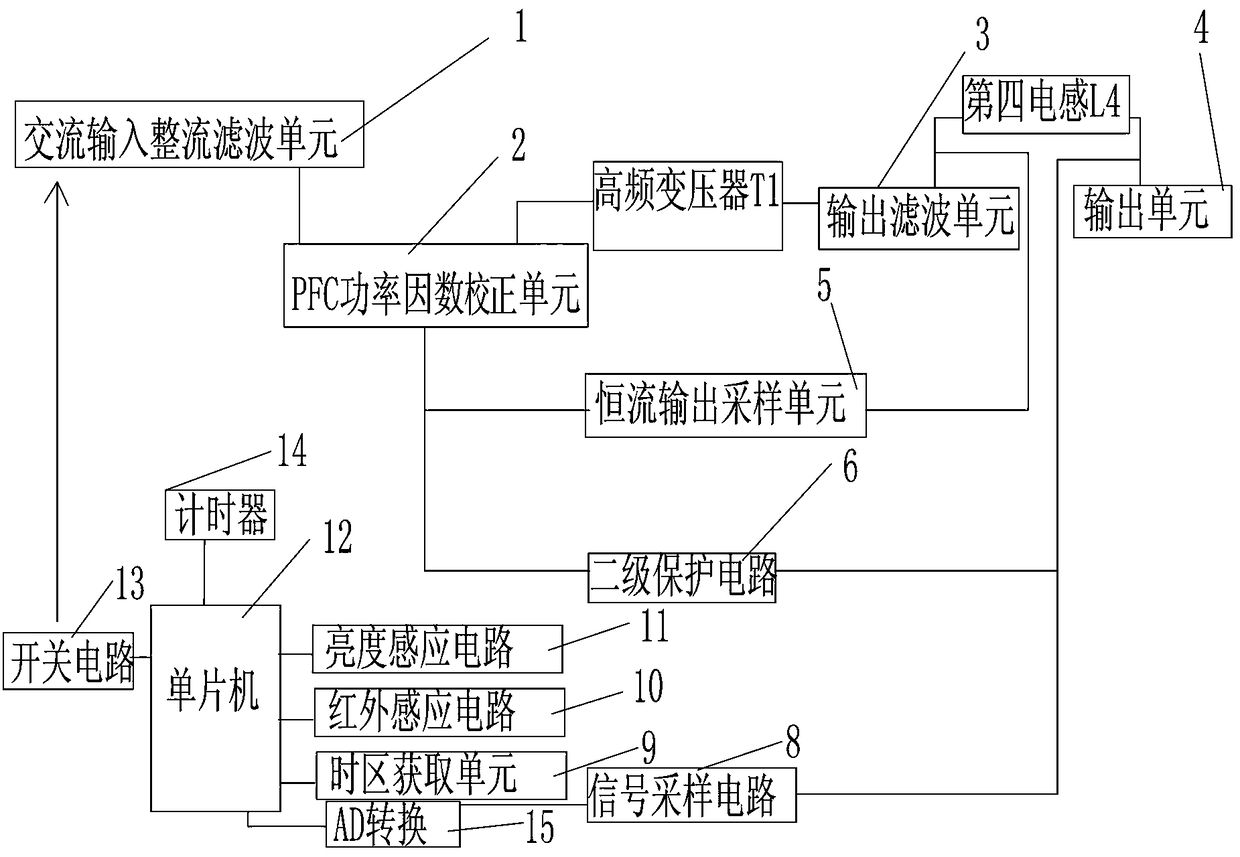

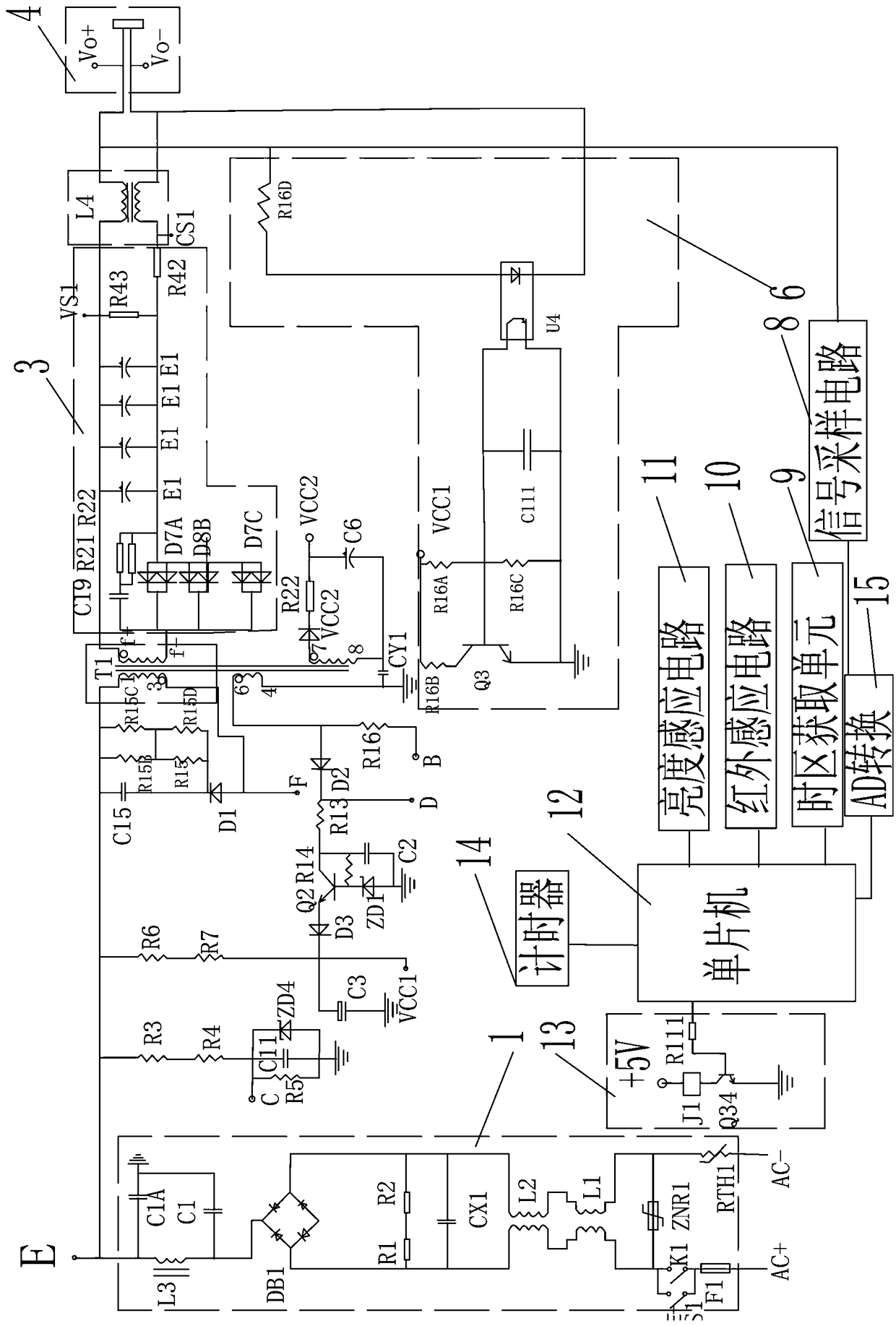

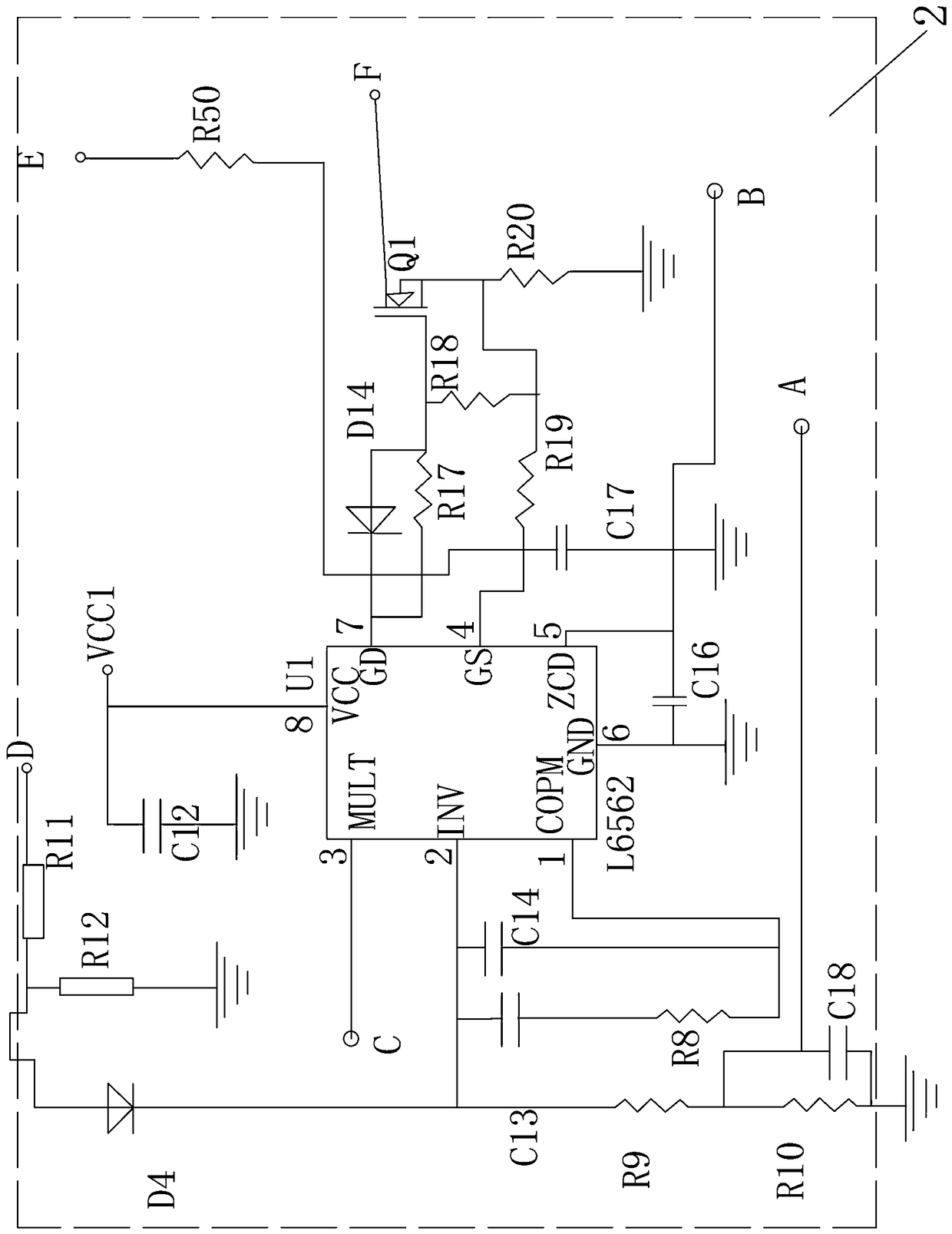

[0027] Such as figure 1 , figure 2 As shown, an intelligent PFC constant current drive power supply circuit provided by the present invention includes an AC input rectification filter unit 1, a PFC power factor correction unit 2, a high-frequency transformer T1, an output filter unit 3, and an output unit 4. The PFC power The factor correction unit 2 is connected to the peripheral circuit through a PFC power factor adjustment chip U1 and is connected to the high-frequency transformer T1 through a field effect transistor Q1. The output of the output filter unit 3 is connected to the output unit 4 through the fourth inductance L4, and the output The output terminal in the filter unit 3 is connected with the PFC power factor correction unit 2 through a constant current output sampling unit 5, once the output overcurrent is sent immediately to the PFC power factor correction unit 2, the final control output current is in a constant current state, so The output unit 4 feeds back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com