Fully-automatic food processing and conveying device

A transportation device and food processing technology, which is applied in transportation and packaging, food forming, conveyors, etc., can solve the problems of uneven product water volume, achieve the effects of saving manpower, reducing production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

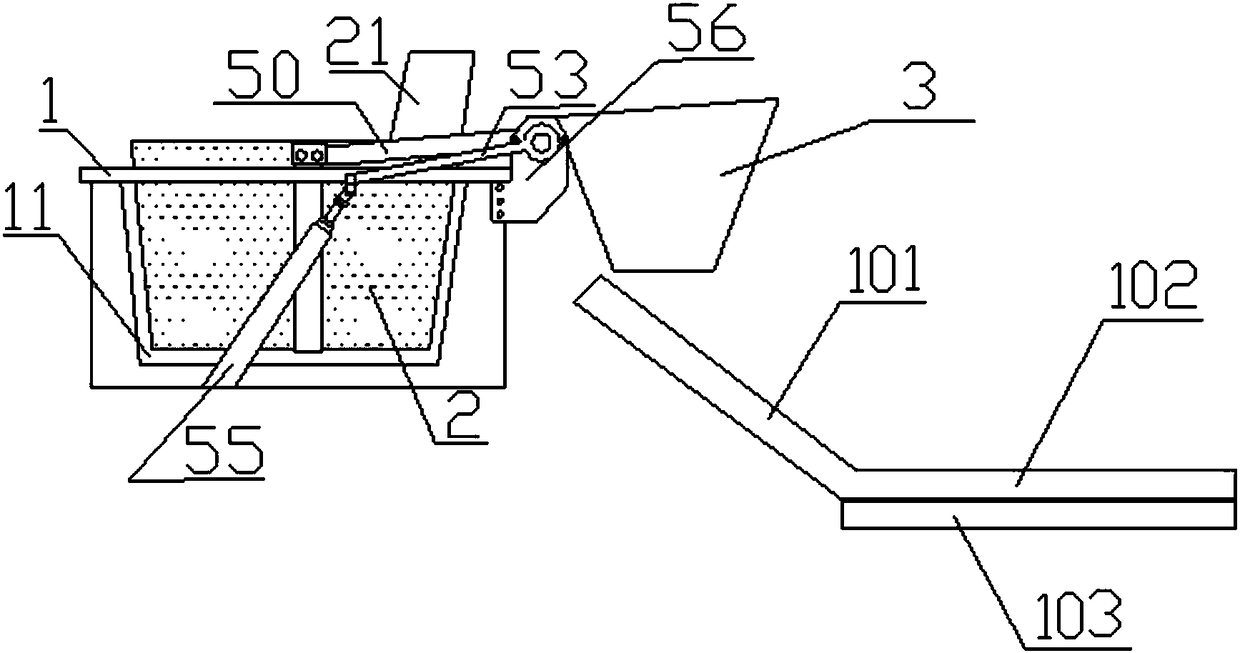

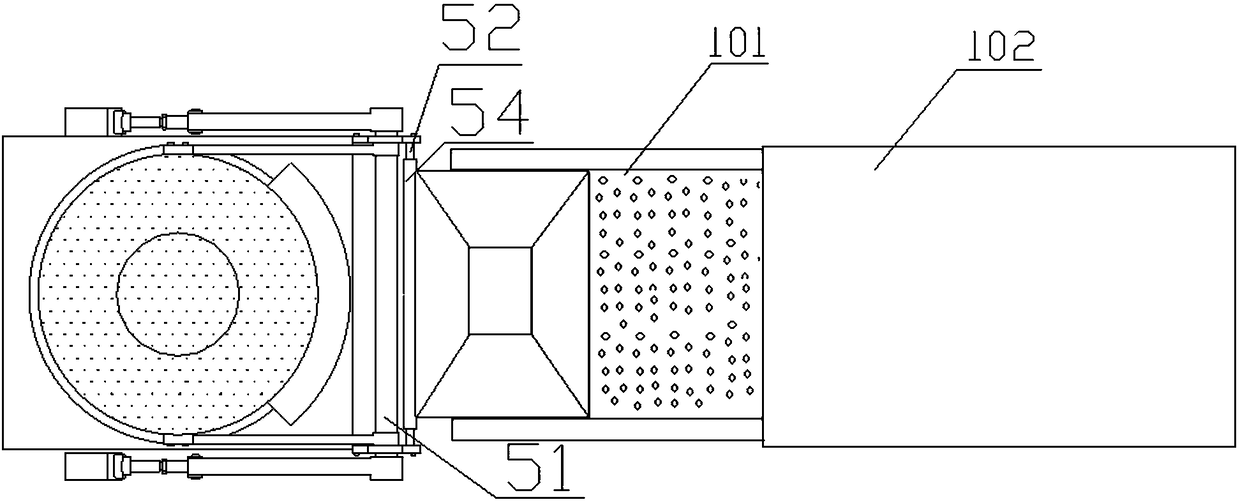

[0029] Such as Figure 1 to Figure 2 As shown, a full-automatic food processing and transportation device is capable of boiling water and drying and transporting food, including a processing device and a transportation device, wherein the processing device includes a workbench 1, a material basket 2, and a discharge funnel 3 , overturning mechanism, control panel, power unit, heating assembly, a pot body 11 for placing the material basket 2 is provided in the workbench 1, and a material guide plate 21 extending along the opening direction of the material basket 2 is provided on the material basket 2, and the material guide The plate 21 is arranged on the side of the material basket 2 close to the discharge funnel 3, and the control panel, the power device, the time monitoring device, and the heating assembly are all arranged in the workbench 1, and the heating assembly is arranged at the bottom of the pot body for feeding into the pot body. Water, the control panel is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com