Citric acid automatic-soaking cleaning and descaling device and method for water ionizer

A technology of citric acid and electrolyzed water, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as cumbersome operation and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

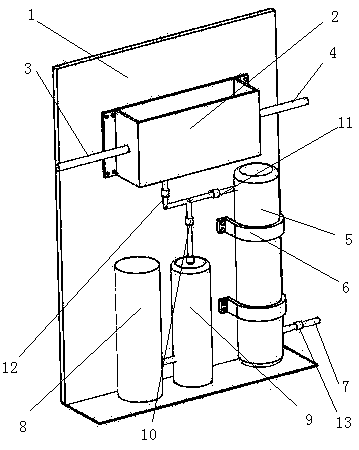

[0016] As a specific embodiment of the structure of the present invention, the cleaning and descaling method of the citric acid automatic immersion cleaning and descaling device of the electrolyzed water machine, the specific steps are as follows:

[0017] Step 1: Use the system to automatically determine that the electrolyzed water machine has been used to the set workload, and then automatically soak the electrolyzer and the citric acid in the outlet pipe for cleaning and descaling;

[0018] Step 2: When the electrolyzed water machine is working normally, since the one-way valve 10 is in the closed state, the tap water enters the filter element 5 through the opened water inlet solenoid valve 13, and the purified water filtered by the electrolyzed water machine filter element 5 is directly supplied to the electrolytic cell 2, without Enter the citric acid container 8, when the electrolyzed water machine enters the citric acid automatic soaking cleaning and descaling state, bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com