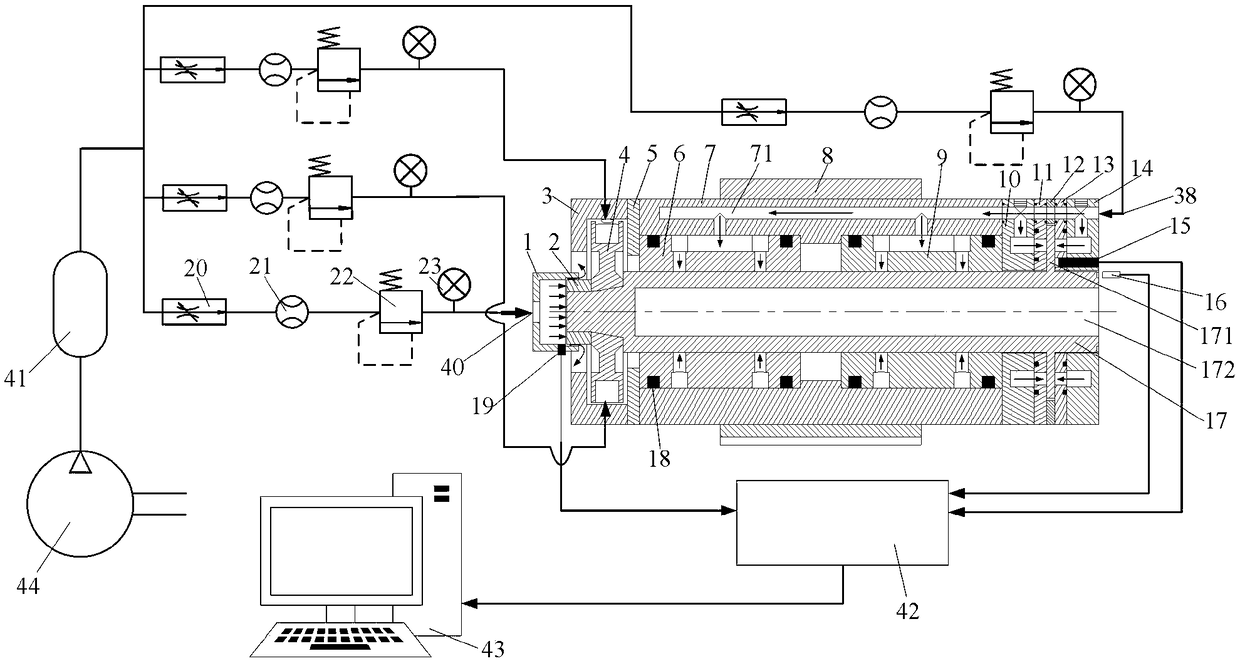

Testing system and testing method for high speed performance of aerostatic thrust bearings

An aerostatic pressure and thrust bearing technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as loading and measuring device damage, reduce wear and heat, and overcome severe wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

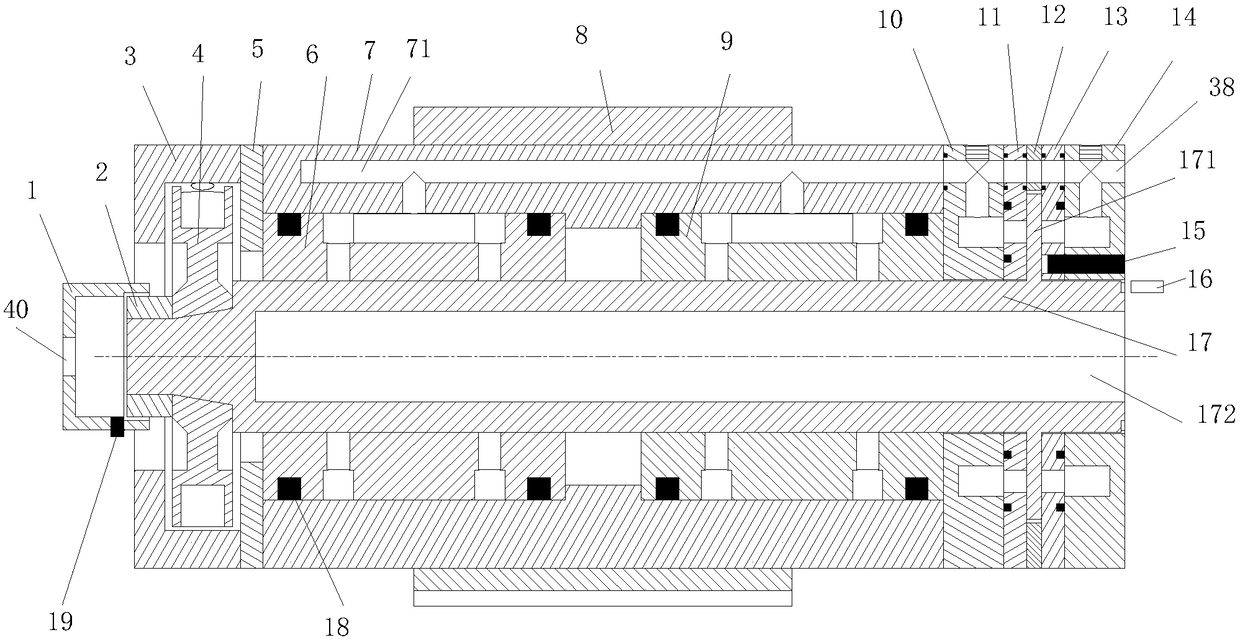

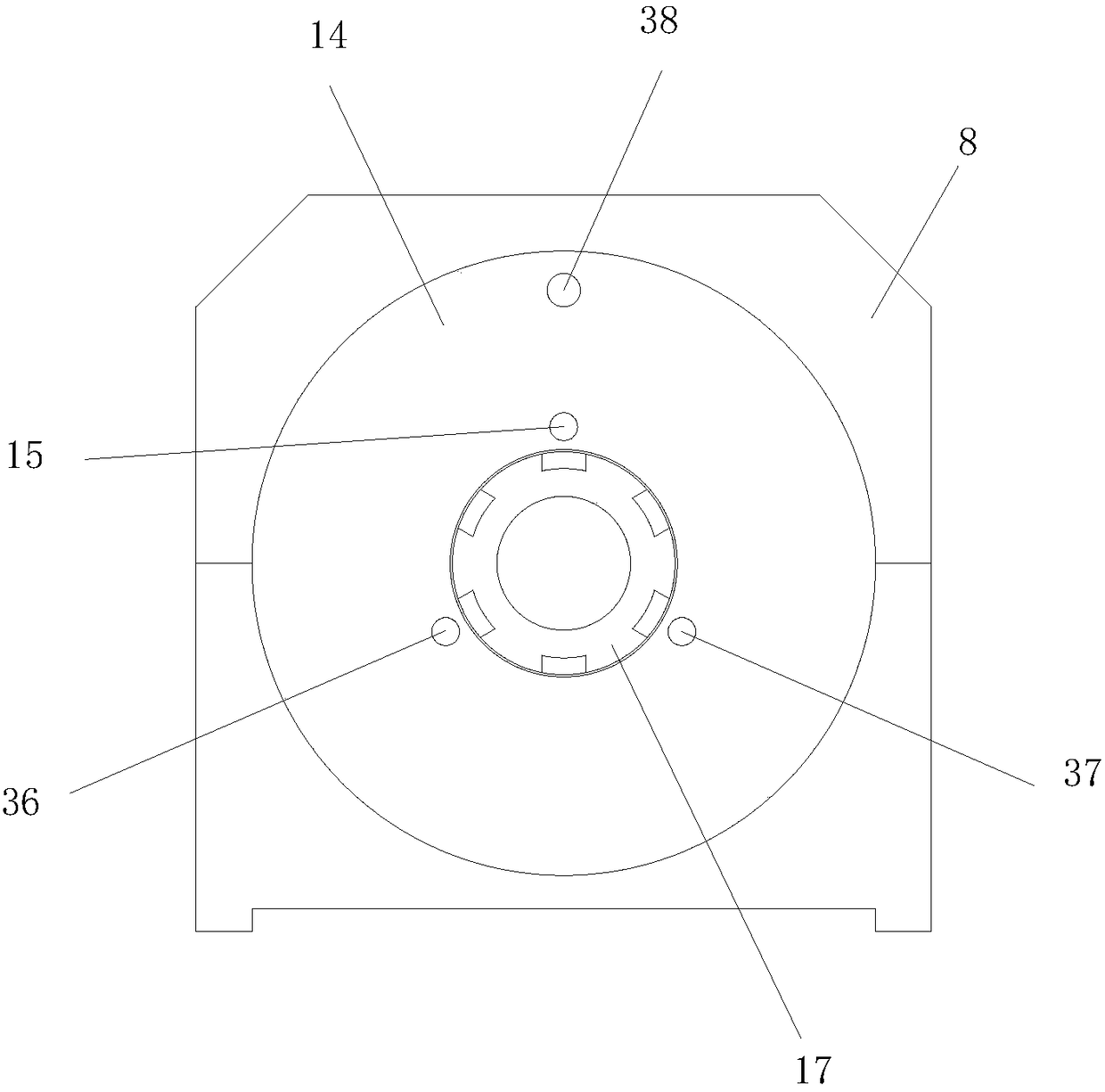

[0034] see Figure 1 to Figure 5 , this embodiment discloses a high-speed performance test system for aerostatic thrust bearings, the test system includes an annular shell 7, the annular shell 7 is clamped and fixed by a base 8, and the base 8 distributes upper clamping parts and lower clamps The tightening part is used to clamp and fix the annular shell 7 by combining the upper clamping part and the lower clamping part. The inner cavity of the annular casing 7 is provided with a shaft core 17, and the shaft core 17 is provided with a hollow hole 172. The left and right ends of the shaft core 17 extend outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com