Magnetic fluid seal

A magnetic fluid and seal technology, applied in the direction of engine seals, bearing components, engine components, etc., can solve the problems of shortening the life of the sealing film, poor sealing performance of the sealing film, and different temperature environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

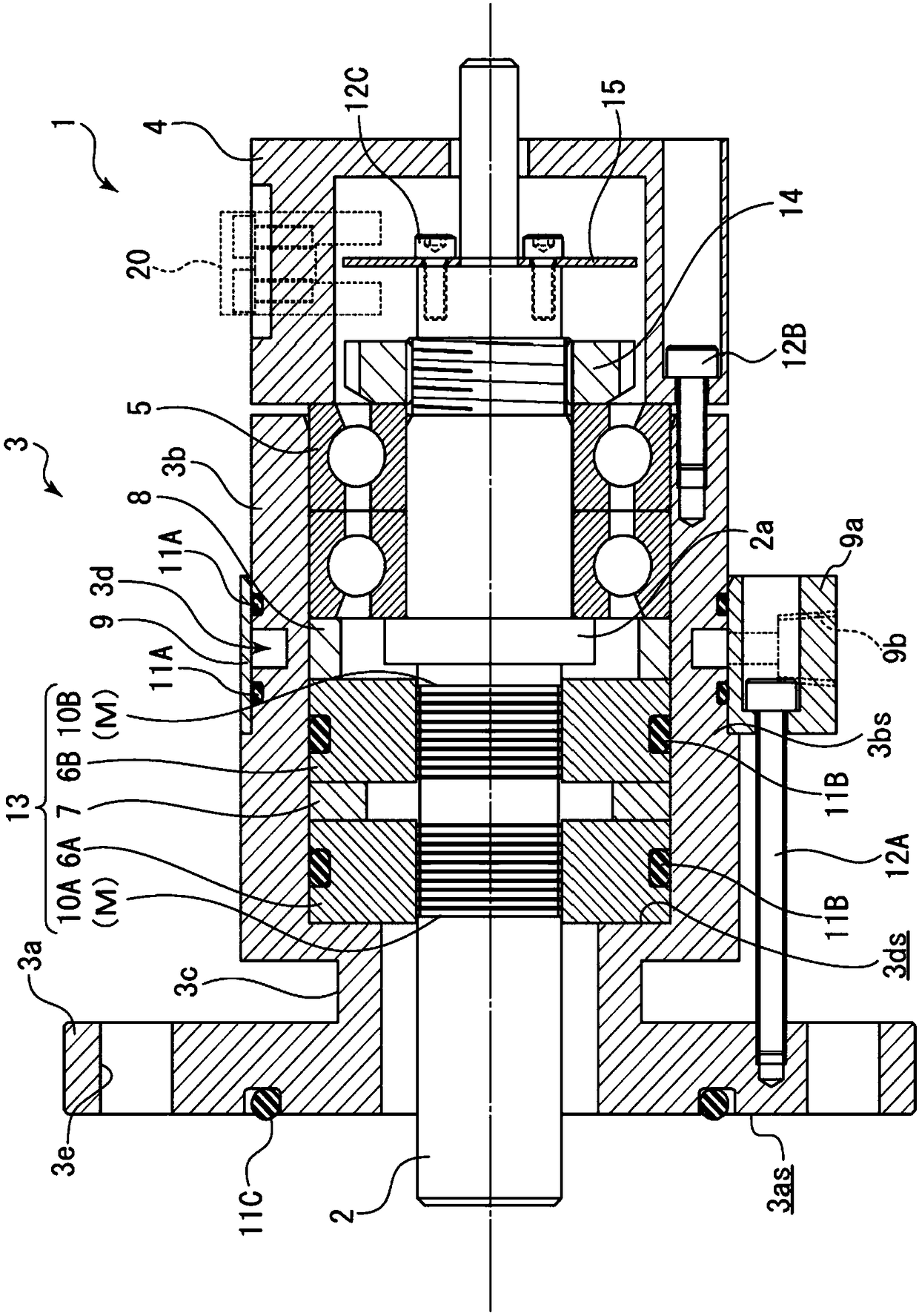

[0037] First, the structure of the magnetic fluid seal of Example 1 will be described.

[0038] Such as figure 1 As shown, the magnetic fluid seal 1 of the present invention has a seal portion 13, and the seal portion 13 is composed of the following members as a member for performing a main function, that is, magnetic pole members 6A, 6B, which are mounted on a fluid machine The rotating shaft 2; the magnetic force generating part 7, which is arranged between the magnetic pole member 6A and the magnetic pole member 6B, can form a magnetic pole on the magnetic pole member 6A, 6B; and the magnetic fluid 10A, 10B, which can be formed along the magnetic pole member. The magnetic circuit between 6A, 6B and the rotary shaft 2 forms a sealing film M, M. In this way, the sealing film M formed along the rotating shaft 2 is used to form a connection between the rotating shaft 2 of the magnetic fluid seal 1 and the outer cylinder member 3 mounted on the casing (not shown) of the fluid ...

Embodiment 2

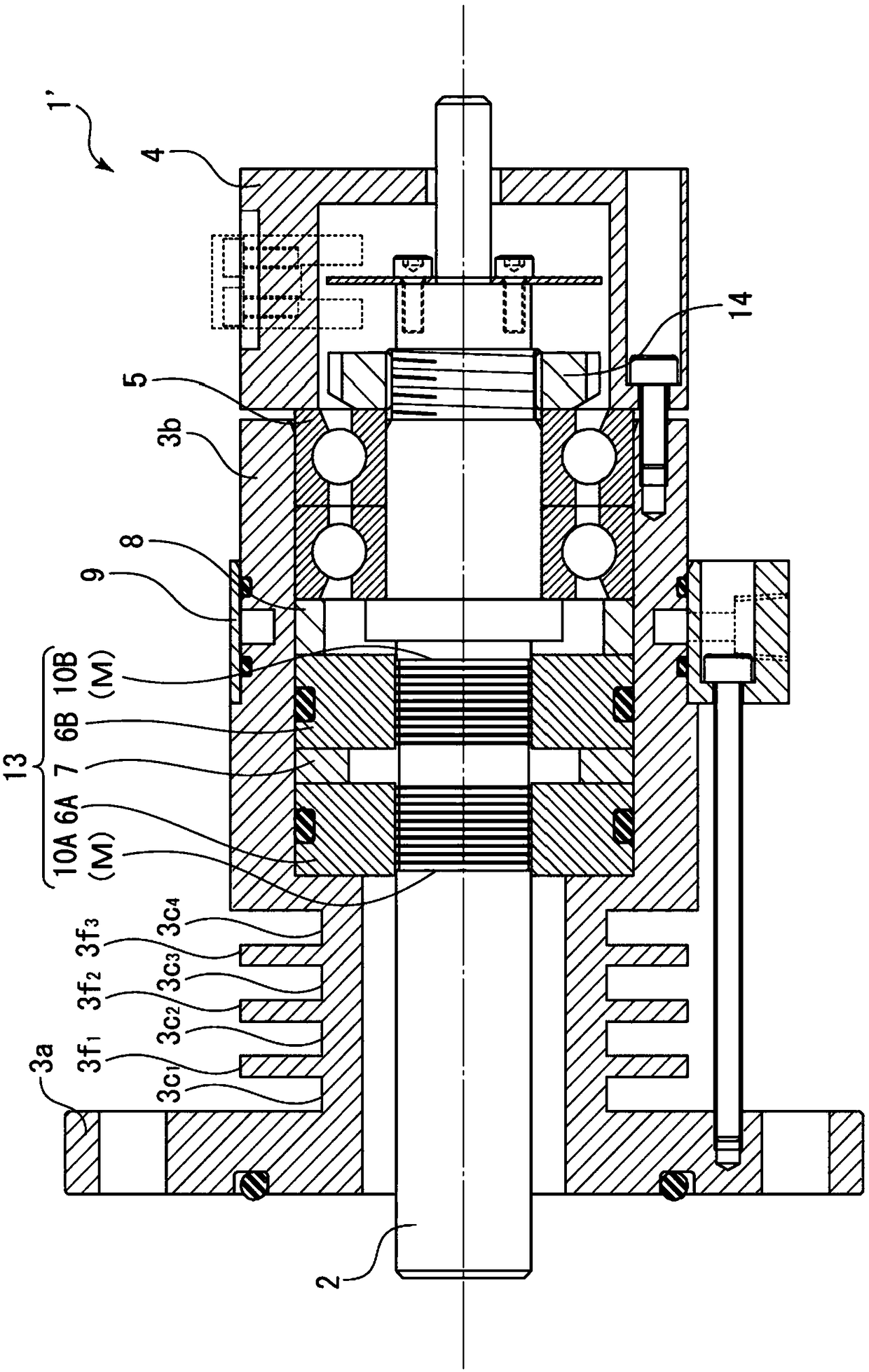

[0062] Next, the structure of the magnetic fluid seal of Example 2 will be described. In addition, the description of the same structure as that of the first embodiment is omitted.

[0063] Such as figure 2 As shown, in the magnetic fluid seal 1' of Example 2, a small-diameter portion 3c is provided as a so-called heat sink between the flange portion 3a and the outer cylinder portion 3b. 1 、3c 2 、3c 3 、3c 4 and a circular flat plate 3f extending in the outer diameter direction between these small diameter portions 1 、3f 2 、3f 3 . By providing a plurality of small-diameter parts 3c like this 1 、3c 2 、3c 3 、3c 4 and multiple circular plates 3f 1 、3f 2 、3f 3 That is, the heat dissipation fins can increase the surface area between the flange portion 3a and the outer cylinder portion 3b, thereby achieving a more remarkable heat dissipation effect. That is, the small diameter portion 3c 1 、3c 2 、3c 3 、3c 4 Functioning as the heat insulating member of the present ...

Embodiment 3

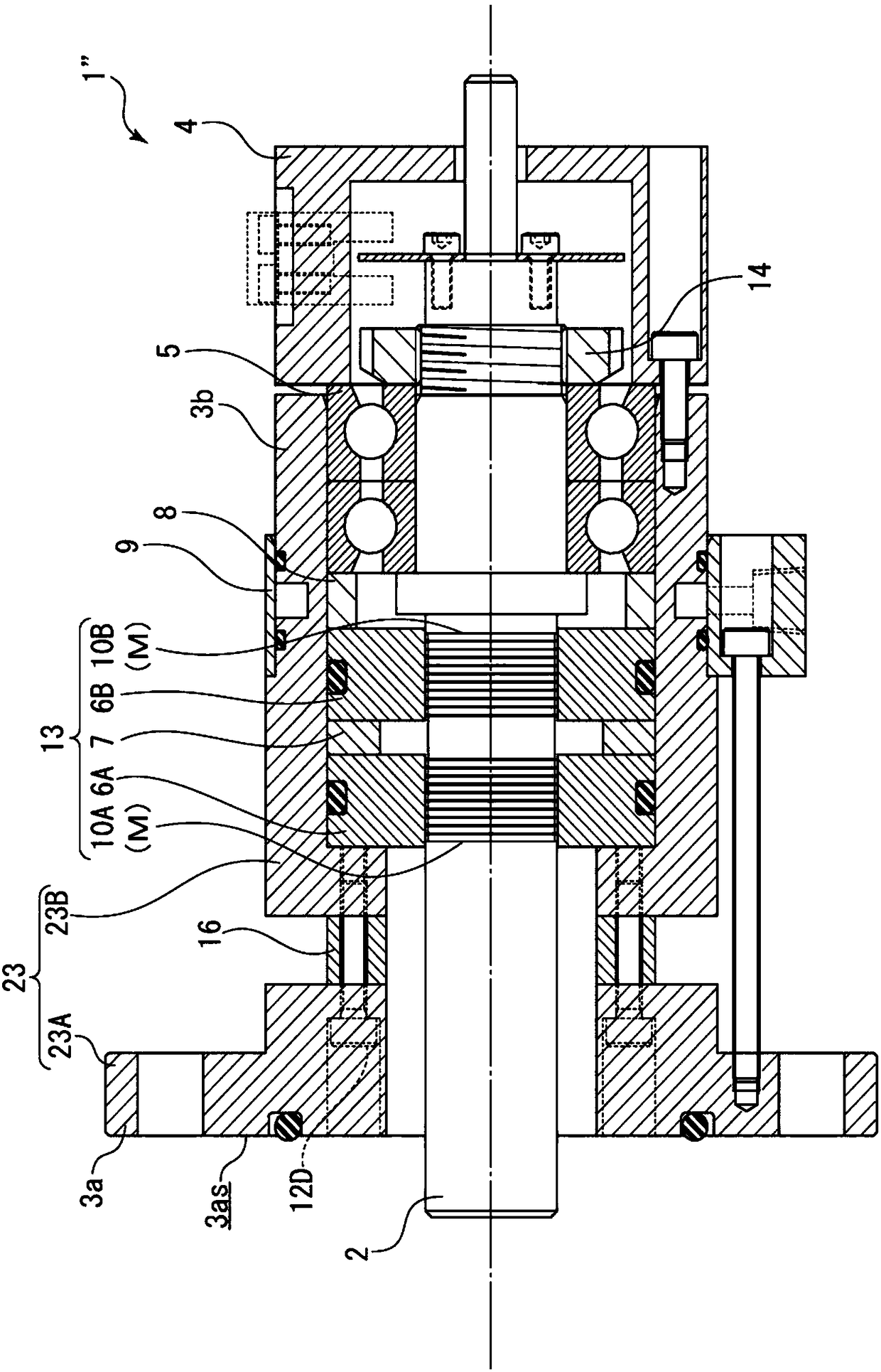

[0065] Next, the structure of the magnetic fluid seal of Example 3 will be described. In addition, the description of the same structure as that of the first embodiment is omitted.

[0066] Such as image 3 As shown, the outer cylinder member 23 of the magnetic fluid seal 1" of Embodiment 3 is composed of independent members such as a flange member 23A and an outer cylinder member 23B that are independent of each other. The flange member 23A and the outer cylinder member 23B are formed in diameter The small-diameter member 16 whose upward diameter is smaller than that of the outer cylinder member 23B is interposed between the flange member 23A and the outer cylinder member 23B, and is fixed together by the hexagon bolt 12D inserted from the mounting surface 3as of the flange member 23A.

[0067]Here, the small-diameter member 16 is an annular member whose diameter in the radial direction is smaller than that of the outer cylinder member 23B, and its material may be a resin mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com