Coil former for an electrical coil assembly and method for producing an electrical coil assembly

A coil support and electric coil technology, which is applied in coil manufacturing, electromechanical devices, and motor generator manufacturing, can solve the problem of heat dissipation in areas where no castings are placed, and achieve improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

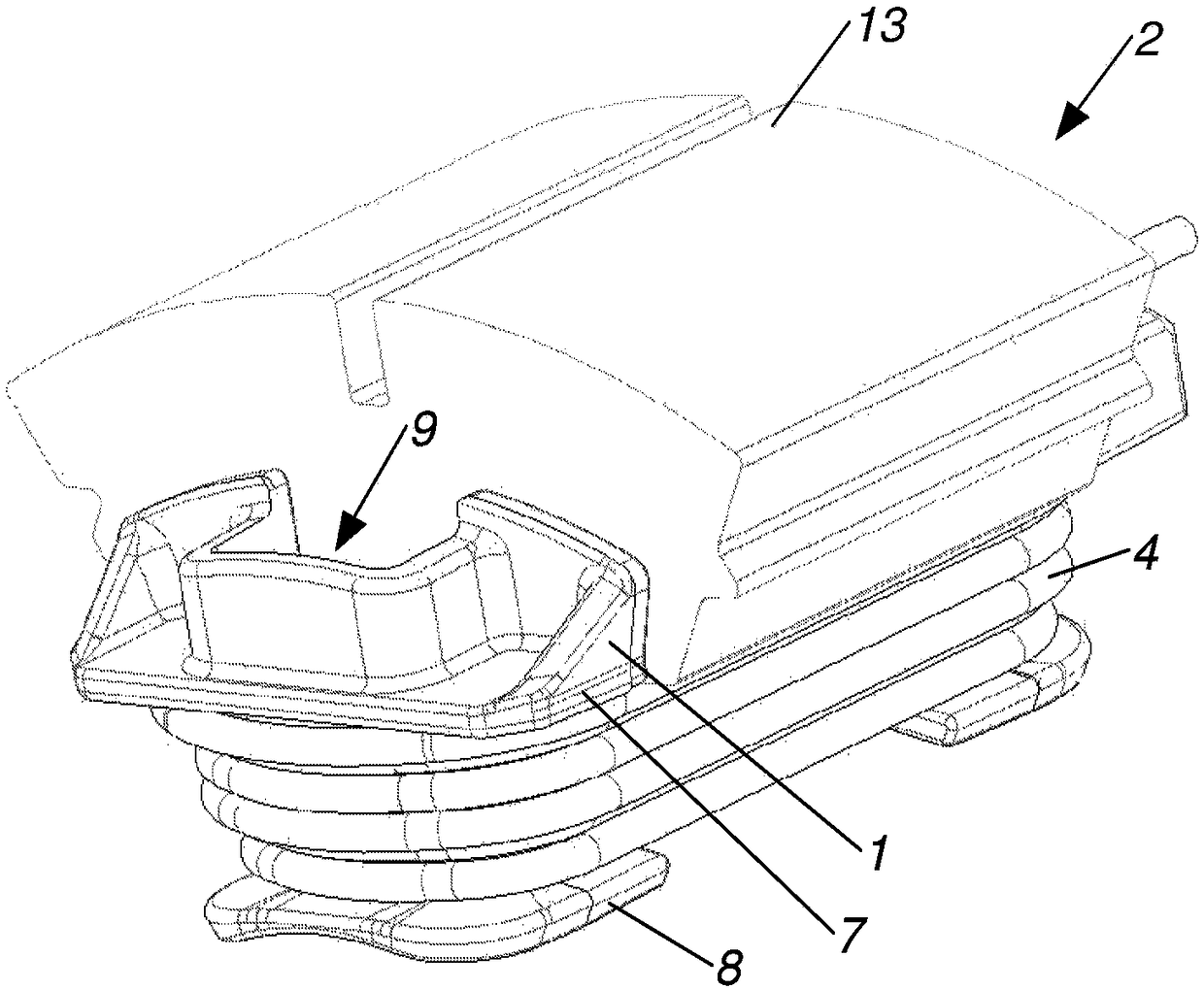

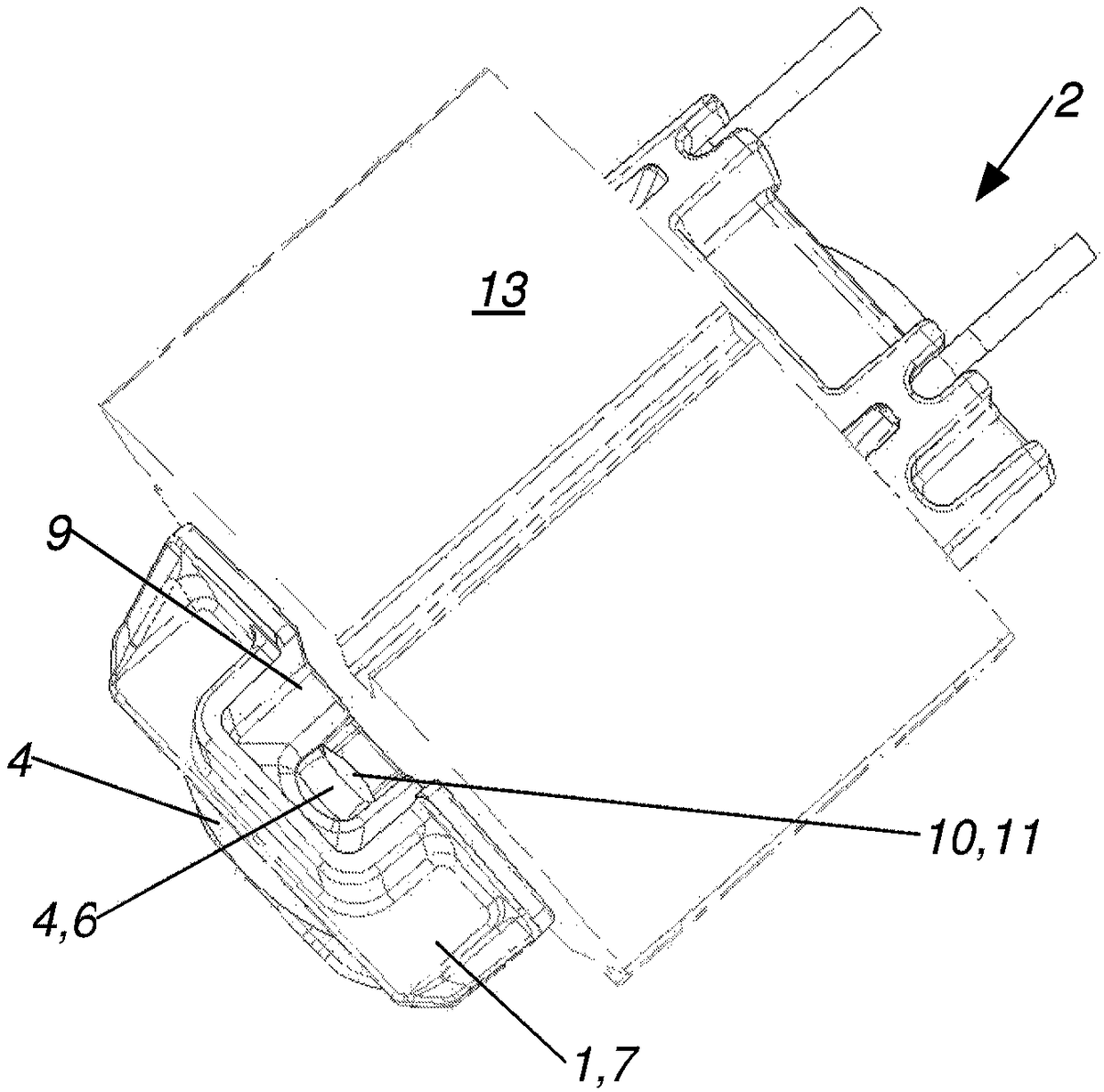

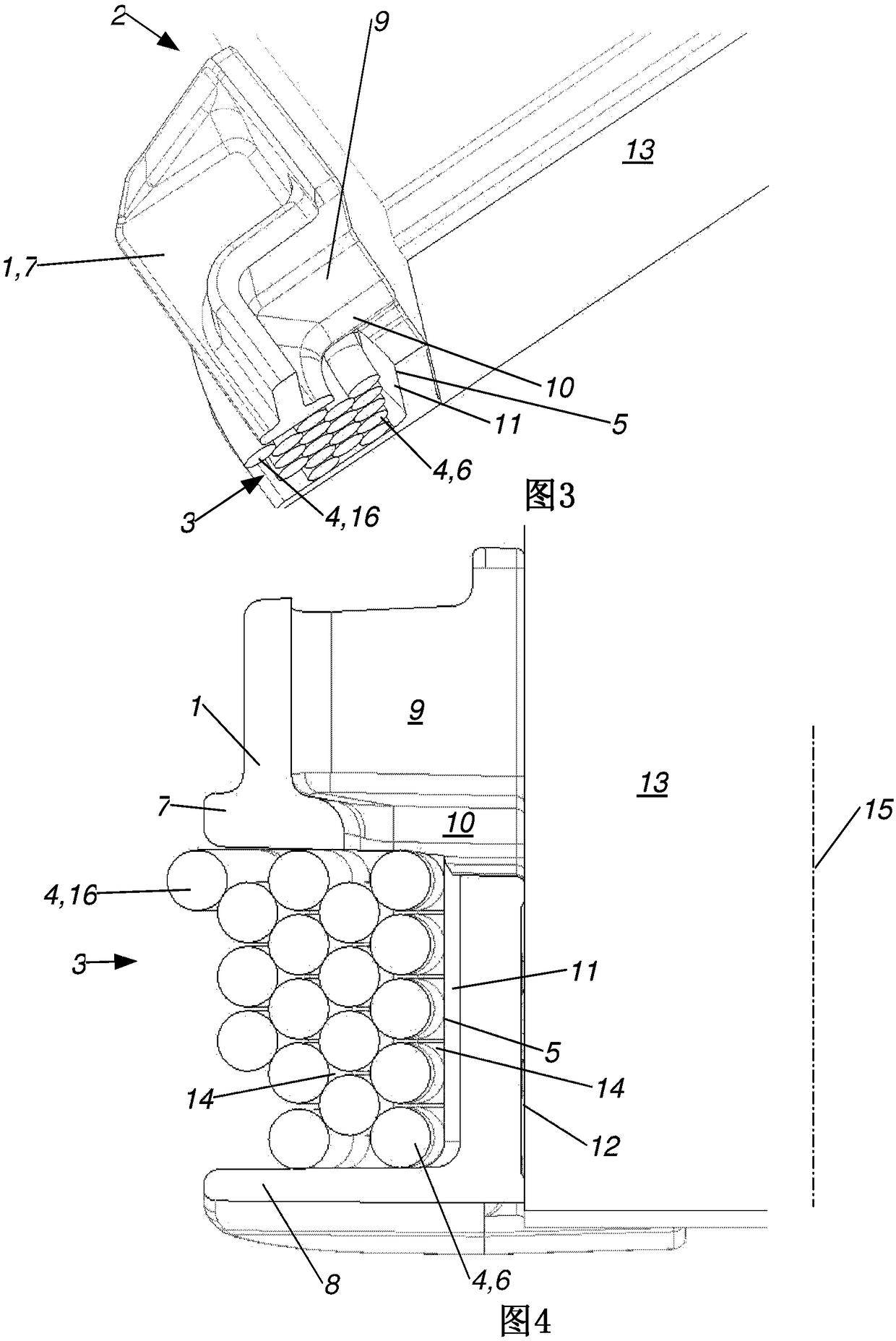

[0026] Figure 1 to Figure 8 Each shows an electrical coil arrangement 2 or a part of such a coil arrangement, which comprises at least one core 13 and at least one coil winding 4 which is wound around at least one region of the core 13 , wherein at the core 13 On at least one peripheral section, the coil carrier 1 is arranged between the core 13 and the coil winding 4 , wherein the coil carrier 1 has a winding receiving area 3 for at least one peripheral section of the coil winding 4 , the winding receiving area 3 Delimited by a winding receiving area inner surface 5 for contact with the innermost winding layer 6 of the coil winding 4 and at least one first end piece 7 protruding from the winding receiving area inner surface 5, wherein at the first end On the side of the component 7 facing away from the winding receiving area 3 is arranged an at least partially enclosed fluid receiving reservoir 9 , wherein the fluid receiving reservoir 9 is connected to the winding receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com