A kind of ruthenium nano metal electrocatalyst and preparation method

An electrocatalyst and nano-metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve good application prospects, wide range of raw material sources, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a kind of preparation method of ruthenium nano metal electrocatalyst, comprises the following steps:

[0042] S1. Preparation of ruthenium phthalocyanine metal organic compounds;

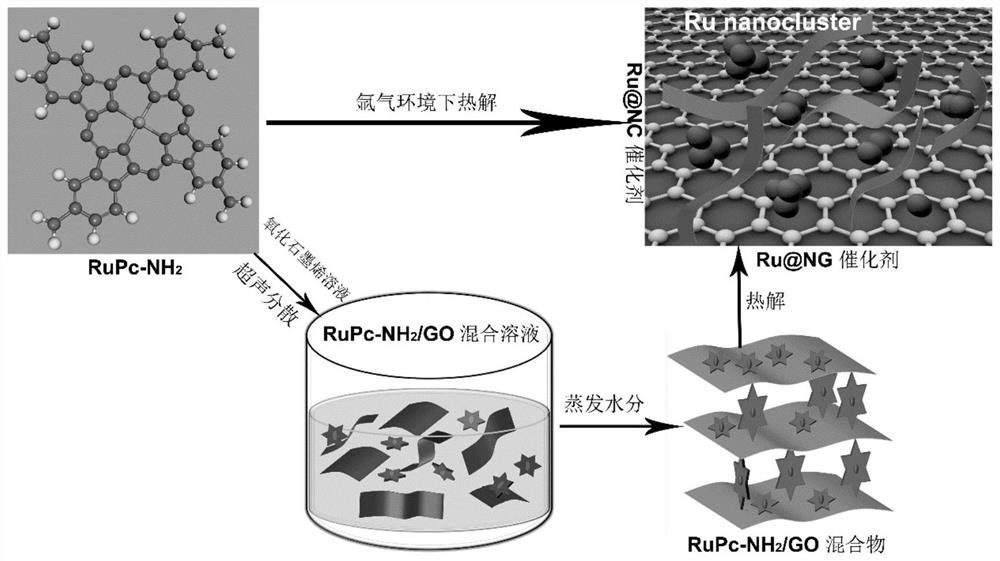

[0043] S2. Dispersing and mixing the ruthenium phthalocyanine metal organic compound with a two-dimensional carbon material to obtain an electrocatalyst precursor;

[0044] S3. Pyrolyzing the electrocatalyst precursor at high temperature under an inert atmosphere to obtain a ruthenium nano metal particle electrocatalyst.

[0045] It can be understood that, in the present invention, what the precursor of preparation electrocatalyst adopts is ruthenium phthalocyanine metal organic compound, and its metal ruthenium (Ru) is chemically bonded Ru-N 4 Fixed at the center of the phthalocyanine heterocycle, while introducing a two-dimensional carbon material to separate the ruthenium phthalocyanine in space, followed by high-temperature pyrolysis under an inert gas, the migrati...

Embodiment 1

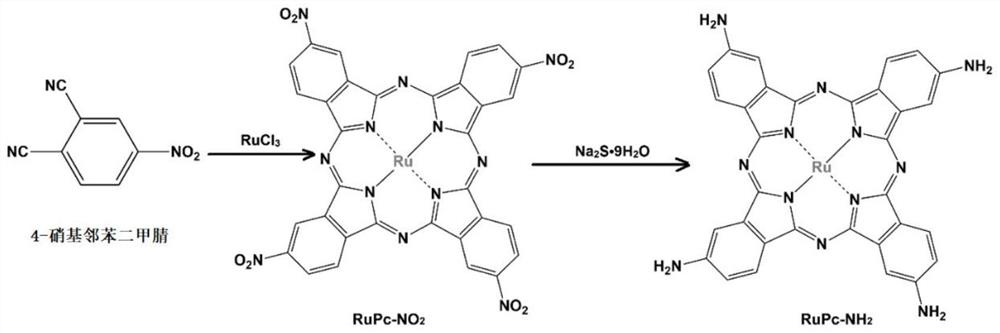

[0048] refer to figure 1 Shown is a schematic diagram of the synthetic route of the ruthenium phthalocyanine metal organic compound in this example.

[0049] Specifically, 7.54g of tetranitrophthalonitrile and 2.25g of ruthenium trichloride (RuCl 3 ) into a three-necked flask, mechanically stirred and mixed evenly, then heated in an oil bath to 160°C to make the reactant in a molten state, maintained at 160°C for 4 hours, and then naturally cooled to room temperature, after grinding, repeated extraction with methanol and acetone to obtain 4 -Nitroruthenium phthalocyanine (RuPc-NO 2 )powder. Pour 4.0g of 4-nitroruthenium phthalocyanine and 18g of sodium sulfide nonahydrate into a three-necked flask, add 150mL of N,N dimethylformamide and react in a water bath at 60°C for 8 hours, and obtain 4-aminoruthenium phthalocyanine through filtration and extraction (RuPc-NH 2 ); the synthesized 4-aminoruthenium phthalocyanine (0.1g) was dispersed in 20mL water, and 2.5mL of graphene ...

Embodiment 2

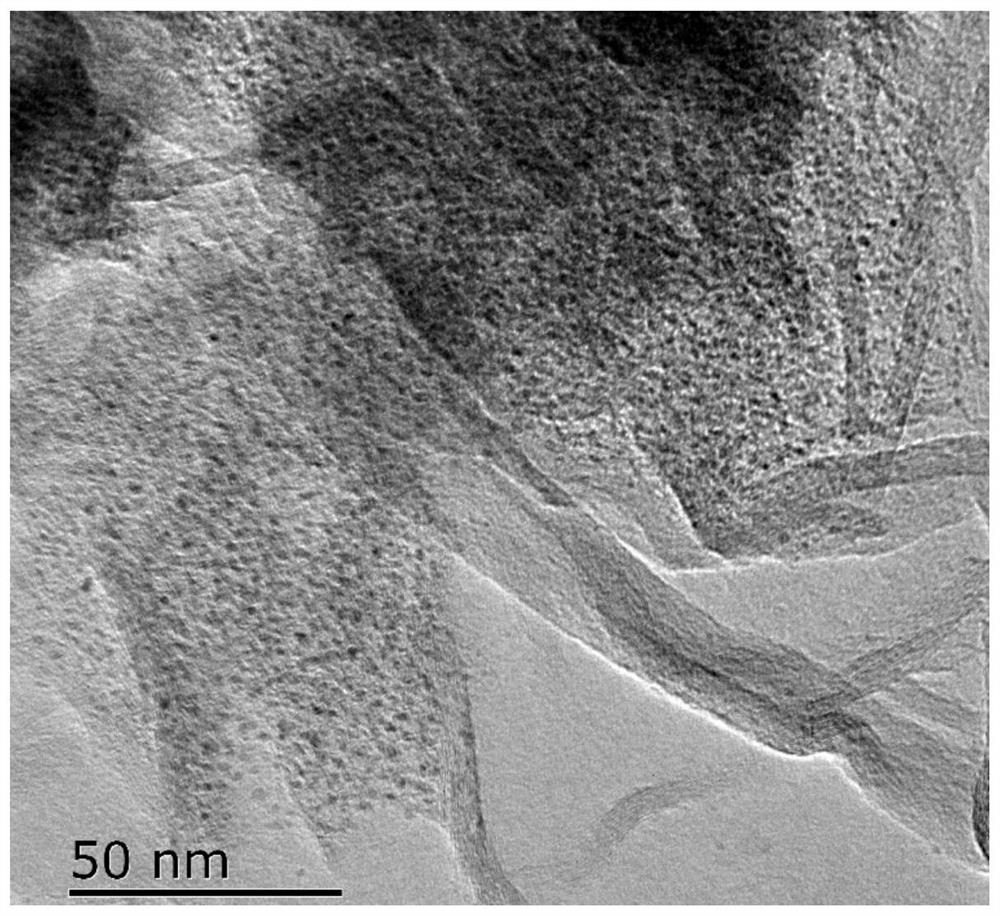

[0052] With the synthetic 4-aminoruthenium phthalocyanine (RuPc-NH 2 ) were directly transferred as a precursor to a tube furnace for pyrolysis. Pyrolysis conditions: under argon atmosphere, the temperature rise range is 30-800°C, the speed is 5°C / min, and the temperature is maintained at 800°C for 2 hours. After natural cooling, the electrocatalyst Ru@NC was obtained after washing with ethanol. In the catalyst, ruthenium atoms in ruthenium phthalocyanine undergo high-temperature thermal reduction to form ruthenium nanoparticles, and nitrogen and carbon elements are converted into nitrogen-doped carbon materials. After statistical analysis of the TEM photos, the particle size distribution of the ruthenium nanoparticles is 1.44±0.36nm. Thermogravimetric analysis showed that the Ru content was 26.5 wt%. The nitrogen adsorption and desorption test shows that the catalyst has a 55.7m 2 g -1 , the pore volume is 0.18cm 3 g -1 , the average pore diameter is 2.73nm.

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com