Scrap iron removing device

A technology of iron filings and installation rods, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of being pressed under the material, insufficient iron removal, high labor intensity, etc., so as to facilitate adsorption removal and avoid The effect of manual scraping and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

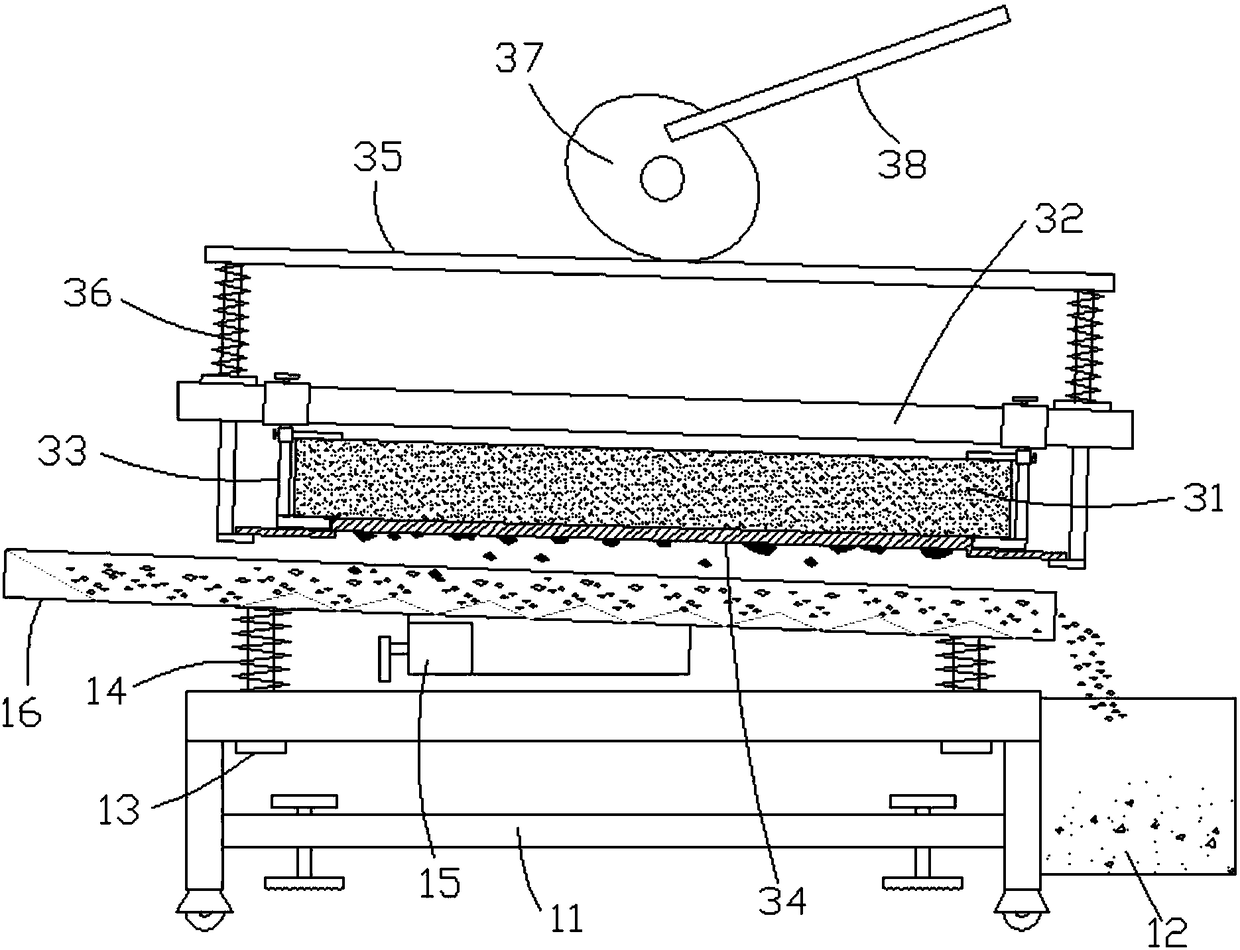

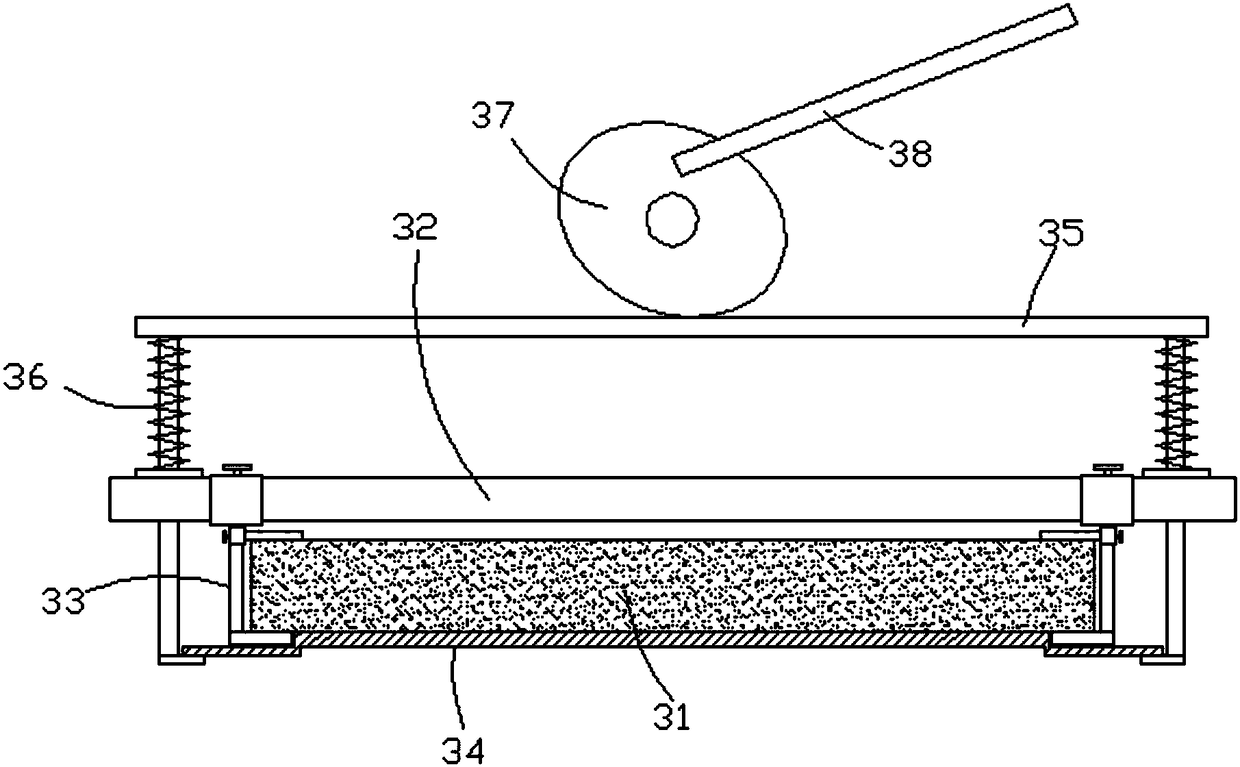

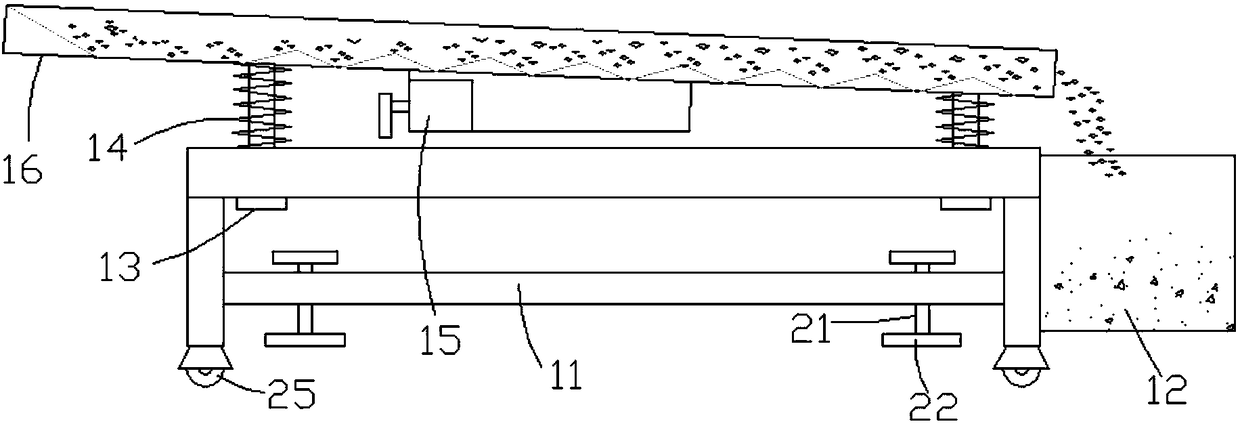

[0021] Such as Figure 1 to Figure 6 , a device for removing iron filings in the present invention, comprising a frame 11, a collection frame 12, a first guide rod 13, a first spring 14, a vibrating motor 15, a feeding trough 16, a permanent magnet 31, a mounting rod 32, a splint 33, Baffle plate 34, mounting bracket 35, second spring 36, cam 37 and handle 38, first guide rod 13 are plugged on the frame 11, and the top of first guide rod 13 is fixedly connected with feeding chute 16, and feeding chute 16 is obliquely arranged, and the discharge opening of feeding chute 16 is placed on the top of collecting frame 12, and collecting frame 12 is fixed on the frame 11. The first spring 14 is sleeved on the first guide rod 13 , and the upper and lower ends of the first spring 14 are in contact with the feeding chute 16 and the frame 11 respectively, and the vibration motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com