Combined screen plate for contact printing

A technology of contact printing and screen printing, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of difficulty in obtaining printing accuracy, high cost, easy distortion of printed graphics, etc., and achieve good coordinate reproducibility and high-precision printing , the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

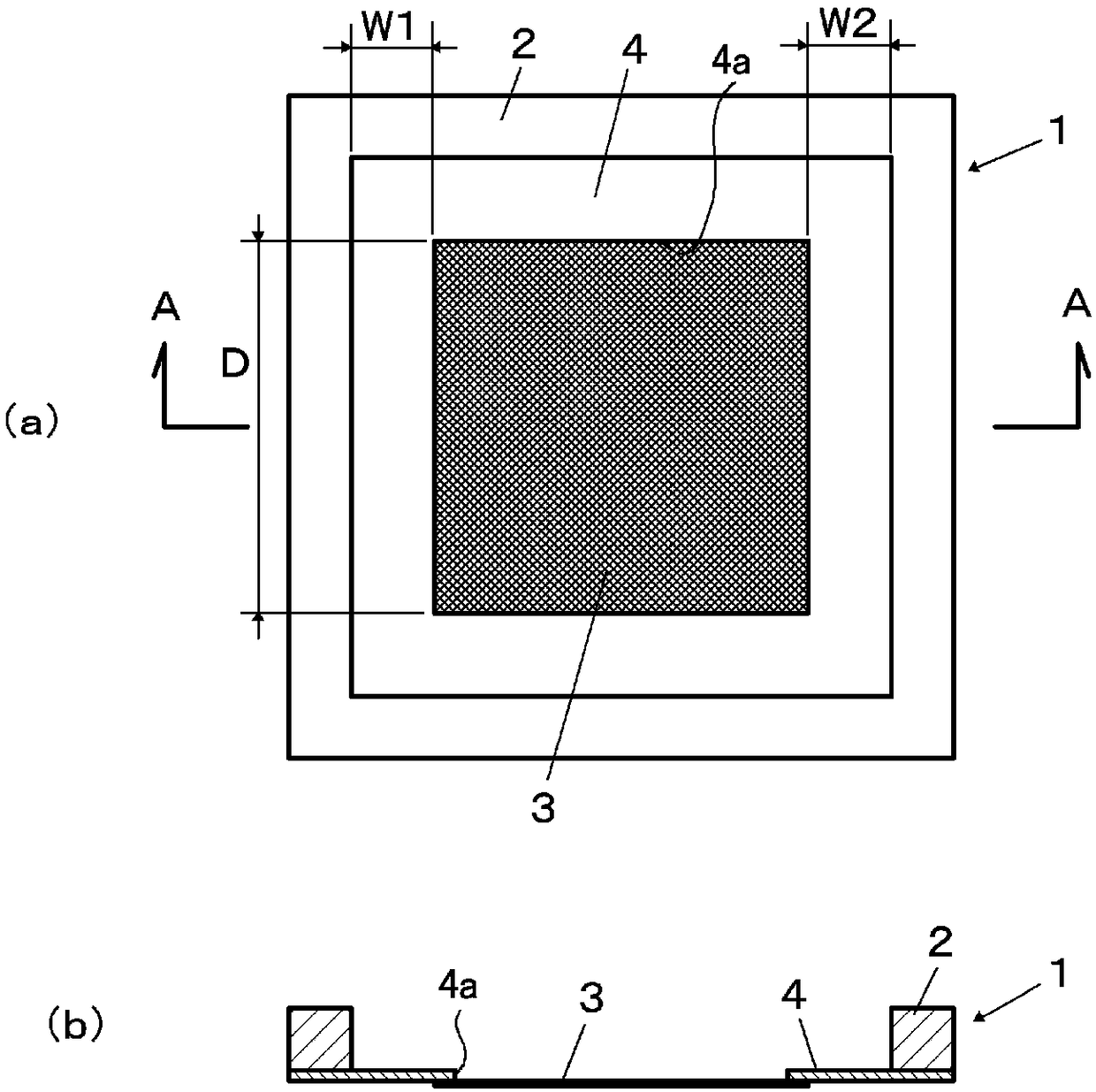

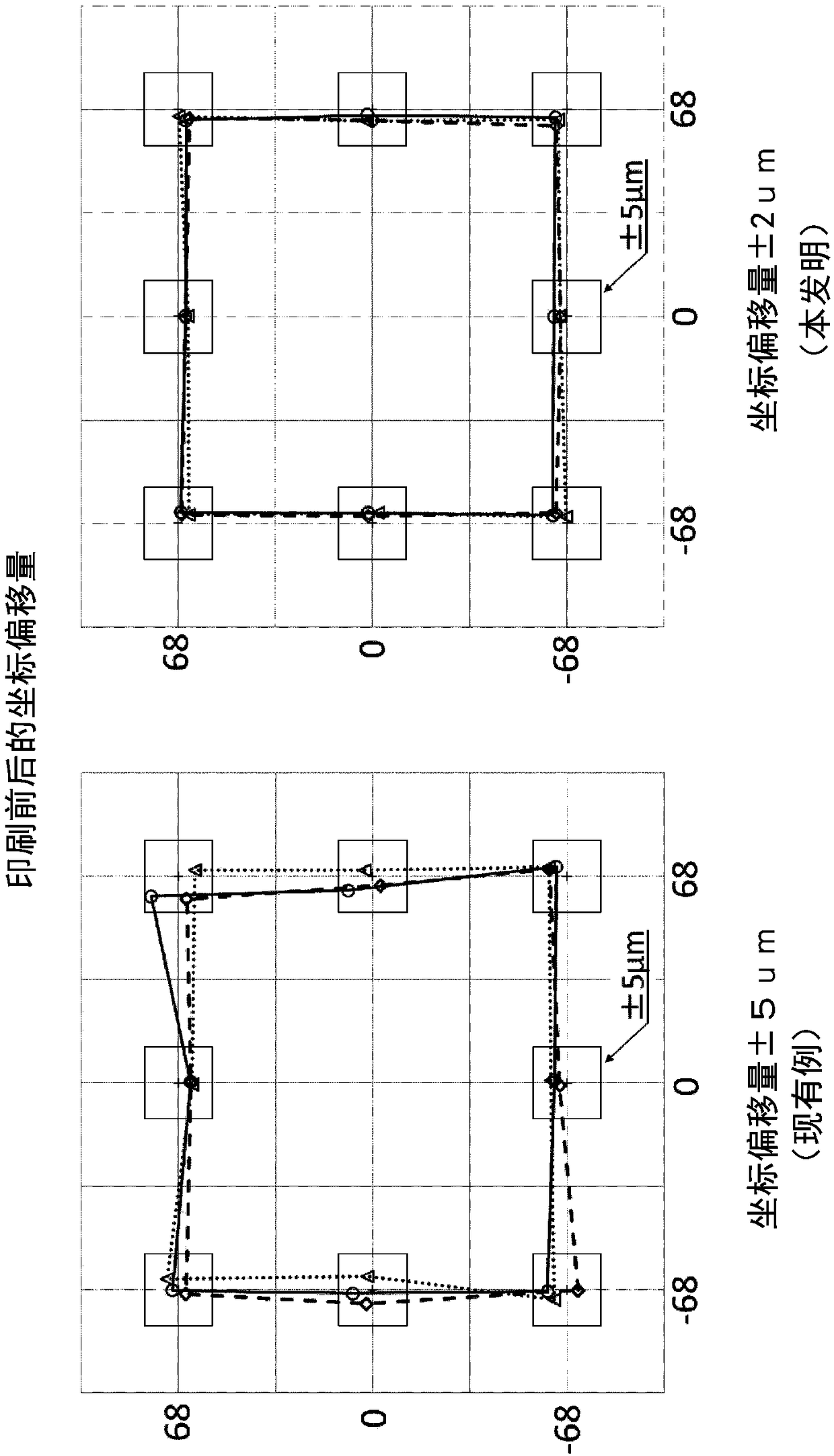

[0044] figure 1 The first embodiment of the combined screen plate for contact printing of the present invention is shown. Above-mentioned combination screen plate 1 comprises: frame 2; Screen screen 3 for printing; Box 2.

[0045] The frame 2 is formed in a quadrangular frame shape from a thick member, and is formed in a size such that the scraper can move inside the frame 2 . The frame 2 is made of metal materials such as aluminum or aluminum alloy. In the conventional screen printing plate, the frame 2 has a function of maintaining the tension of the printing screen 3 , but in the present embodiment, the support body 4 maintains the tension of the printing screen 3 . Therefore, the support body 4 plays a role of firmly supporting the printing screen 3 on the frame 2 .

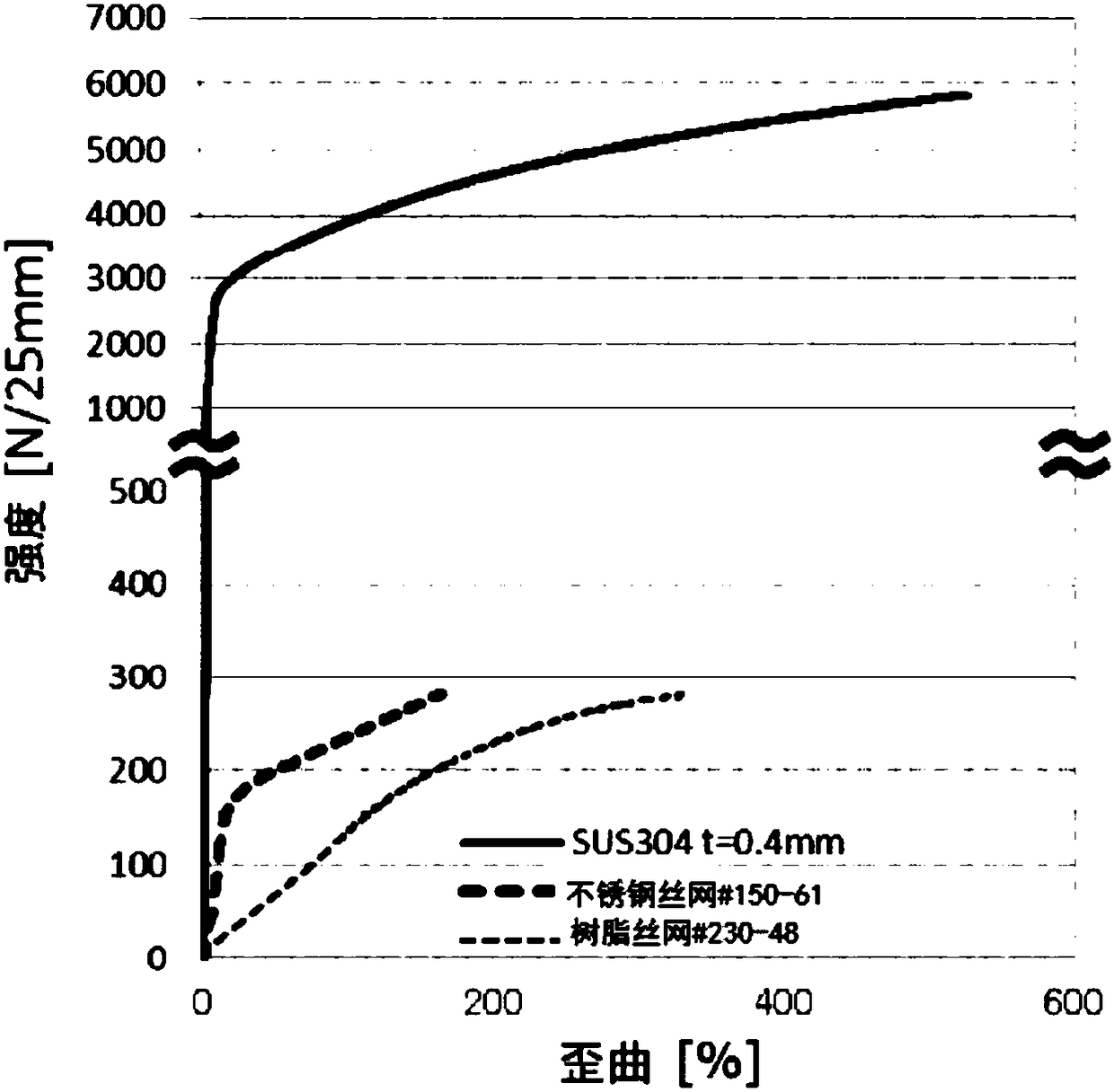

[0046] As the printing screen 3, a metal mesh or a metal mask is used. The metal mesh is a member obtained by weaving fine metal fibers, and for example, a SUS mesh, a tungsten mesh, a high-strength stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com