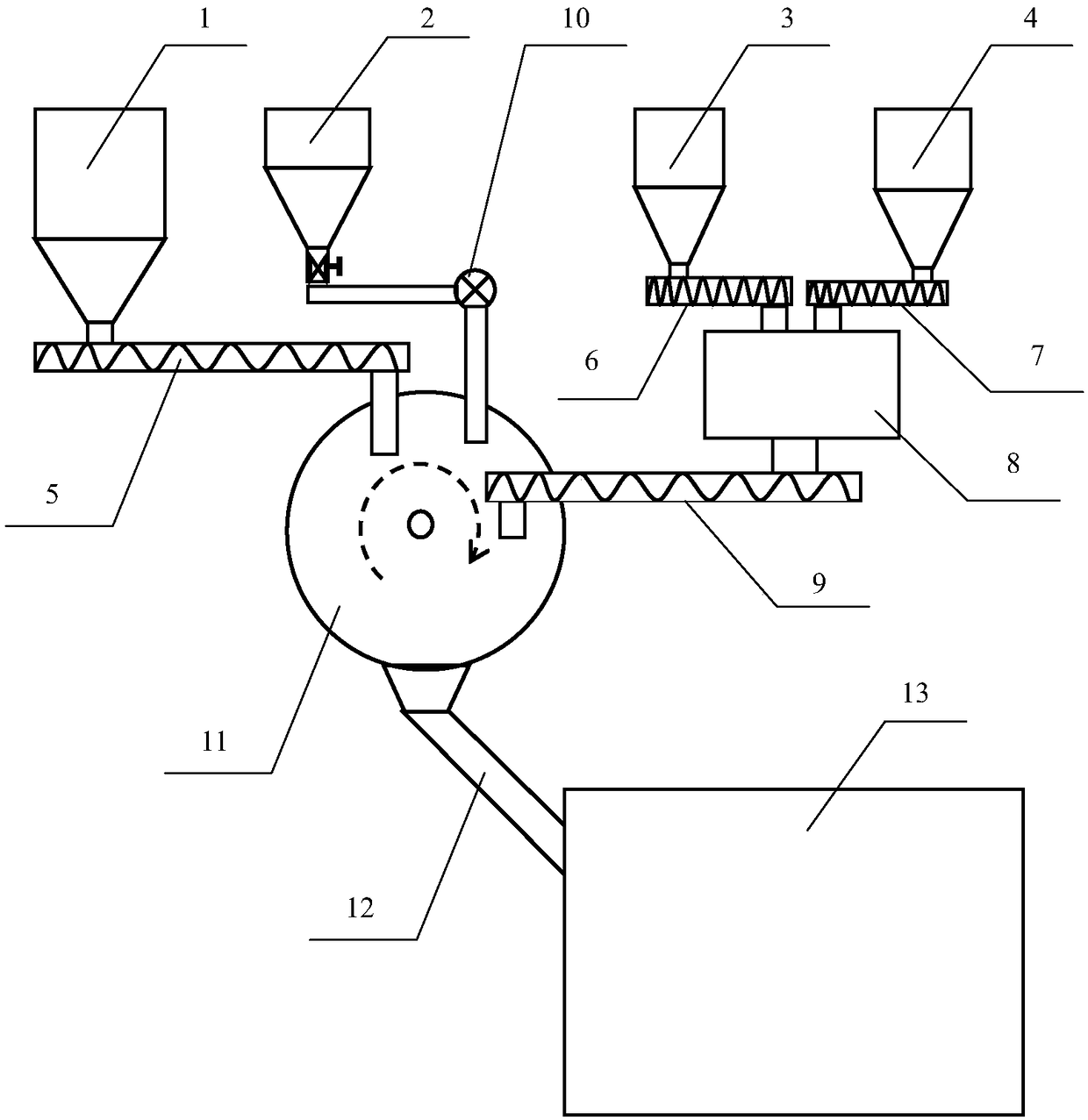

Method for preparing colored sand and production system

A color sand and color technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of easy decolorization of single-layer packaging, high energy consumption in high-temperature processing, and easy bonding of product particles. The effect of reducing bonding agglomeration, improving bonding tightness, and increasing wear resistance and color retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing colored sand in this embodiment, which is made by the following steps: first add the aggregate to a container in a circular motion, then add liquid accounting for 1.5% of the aggregate weight, and roll for 2 minutes to make the bone Wet the surface of the material; then add colored gelling powder accounting for 7% of the aggregate weight, and roll and wrap for 4 minutes, so that the colored gelling powder is wrapped on the liquid-wetted aggregate surface to form a dense first colored wrapping layer; Then add liquid accounting for 1.5% of the aggregate weight, roll for 4 minutes, infiltrate the first colored wrapping layer, after infiltrating the first colored wrapping layer, add colored gelling powder accounting for 7% of the aggregate weight, roll and wrap for 4 minutes , so that the colored gelatinized powder is wrapped on the surface of the liquid-wetted first colored wrapping layer to form a dense second colored wrapping layer; then add liquid ...

Embodiment 2

[0030] A method for preparing colored sand in this embodiment, which is made by the following steps: first add the aggregate to a container for circular motion, then add liquid accounting for 1.3% of the aggregate weight, and roll for 1 minute to make the bone Wet the surface of the material; then add colored gelling powder accounting for 6% of the aggregate weight, roll and wrap for 3 minutes, so that the colored gelling powder is wrapped on the liquid-wetted aggregate surface to form a dense first colored wrapping layer; Then add liquid accounting for 1.3% of the aggregate weight, roll for 3 minutes, infiltrate the first colored wrapping layer, after infiltrating the first colored wrapping layer, add colored gelling powder accounting for 6% of the aggregate weight, roll and wrap for 3 minutes , so that the colored gelatinized powder is wrapped on the surface of the liquid-wetted first colored wrapping layer to form a dense second colored wrapping layer; then add liquid accoun...

Embodiment 3

[0040] A method for preparing colored sand in this embodiment, which is made by the following steps: first add the aggregate to a container in a circular motion, then add liquid accounting for 1.6% of the aggregate weight, and roll for 1 minute to make the bone Wet the surface of the material; then add color gelling powder accounting for 8% of the aggregate weight, roll and wrap for 5 minutes, so that the color gelling powder is wrapped on the liquid-wetted aggregate surface to form a dense first color wrapping layer; Then add liquid accounting for 1.6% of the weight of the aggregate, and roll for 5 minutes to make the liquid fully infiltrate the first colored wrapping layer. Wrapping for 5 minutes, so that the colored gelatinized powder is wrapped on the surface of the first colored wrapping layer wetted by the liquid to form a dense second colored wrapping layer; Two-color wrapping layer, after infiltrating the second colored wrapping layer, add colored gelling powder accoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com