Structure of warm mixing recycling agent

A technology of warm-mixing regenerant and regenerant, which is applied to building components, building structures, building insulation materials, etc., can solve the problems of difficult to control the dosage and inconvenient transportation of regenerant, and achieve improved water stability, flexibility and Viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

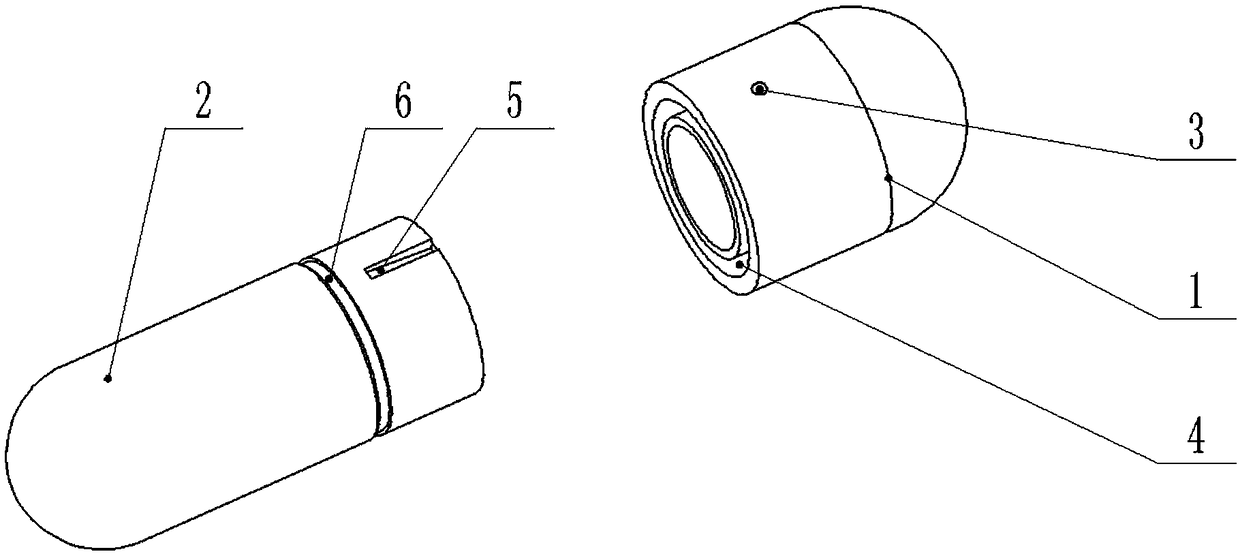

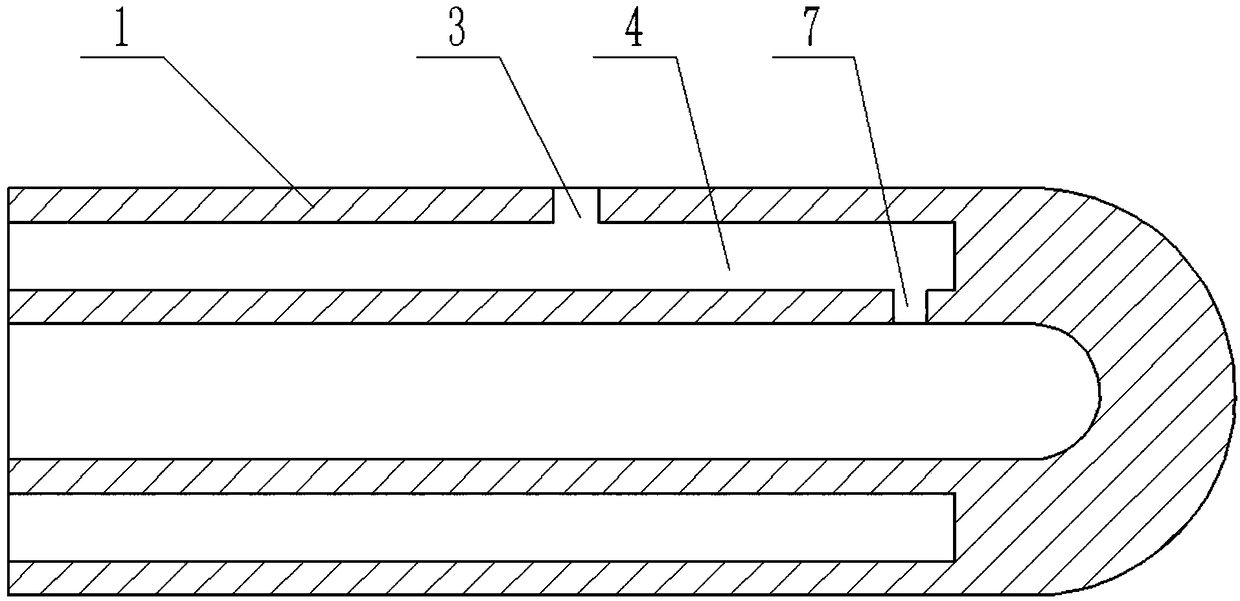

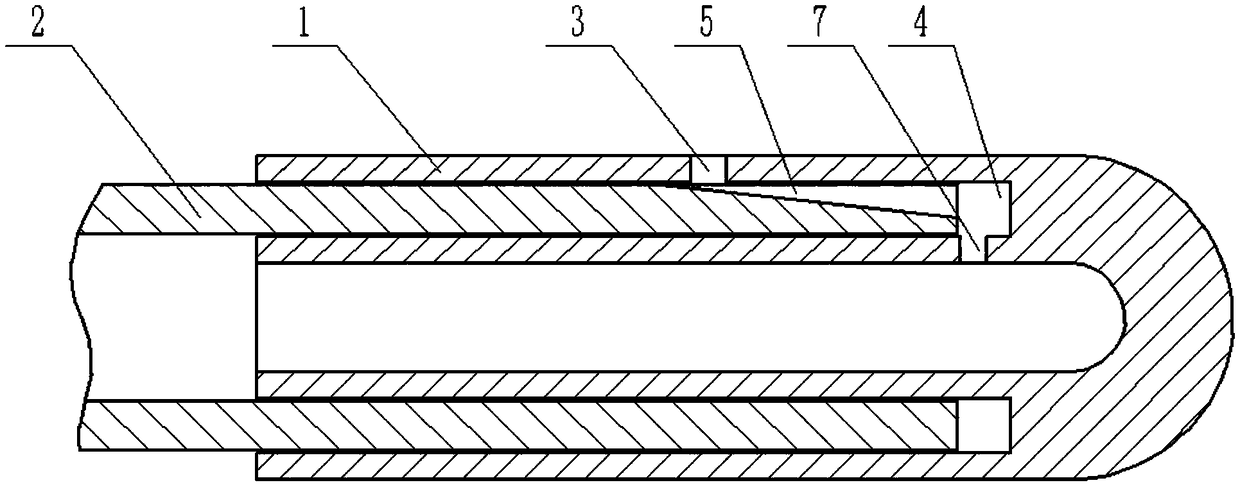

[0030] Such as figure 1As shown, this embodiment is a structure of a warm-mixing regenerant, including a regenerant and a capsule shell. The quality of the components in the regenerant is: 2kg of waste engine oil, 0.05kg of graphene, 2kg of light oil, 0.5kg of glycerol lipids, and 0.9kg of desulfurized rubber powder. The mass of the components of the capsule shell is: fiber 0.1kg, polyene material 0.3kg, devulcanized rubber powder 0.3kg. The capsule shell includes a shell cap 1, a shell 2 and an encapsulating ring. Such as figure 2 , image 3 The left end of the shown shell cap 1 is circumferentially provided with an annular insertion groove 4, and the right bottom of the insertion groove 4 is provided with a flow channel 7, the flow channel 7 is 1 cm away from the right end of the insertion groove 4, and the shell cap 1 is provided with a pouring port 3, The filling port 3 communicates with the insertion groove 4 . The right end of the casing 2 is provided with a draina...

Embodiment 2

[0037] The difference from Example 1 is that the proportioning ratio of the warm-mix regenerant is different, specifically, the quality of the regenerant components is: 5 kg of waste engine oil, 0.5 kg of graphene, 3.5 kg of light oil, 1.5 kg of glycerol lipids, Desulfurized rubber powder 1.35kg. The mass of the components of the capsule shell is: 0.2kg of fiber, 0.5kg of polyene material, and 0.45kg of devulcanized rubber powder.

Embodiment 3

[0039] The difference from Example 1 is that the proportioning ratio of the warm-mix regenerant is different, specifically, the quality of the regenerant components is: 3.5kg of waste engine oil, 0.3kg of graphene, 3.3kg of light oil, 1kg of glycerol lipids, Desulfurized rubber powder 1kg. The mass of the components in the capsule shell is: fiber 0.11kg, polyene material 0.46kg, desulfurized rubber powder 0.33kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com