Mortise-tenon connection structure of fabricated beam-column joints

A technology of beam-column joints and connection structures, which is applied in the direction of building construction and construction, can solve the problems of less application of concrete structures, complex stress, and more construction conditions, so as to reduce the use of workers and related equipment and improve Durability and long-term performance, the effect of reducing the use of formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]In order to make the invention's technical means, creative features, goals and effects easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

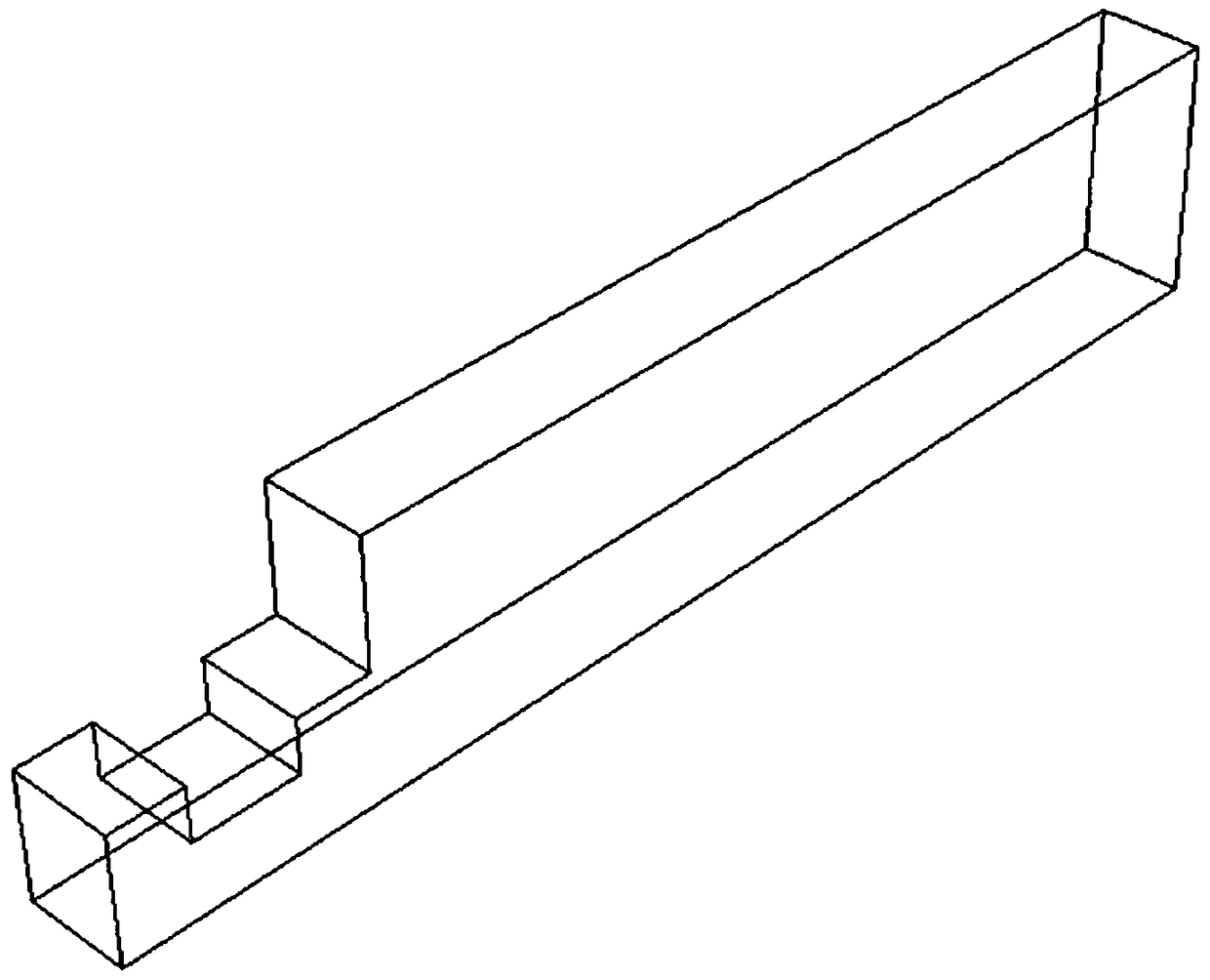

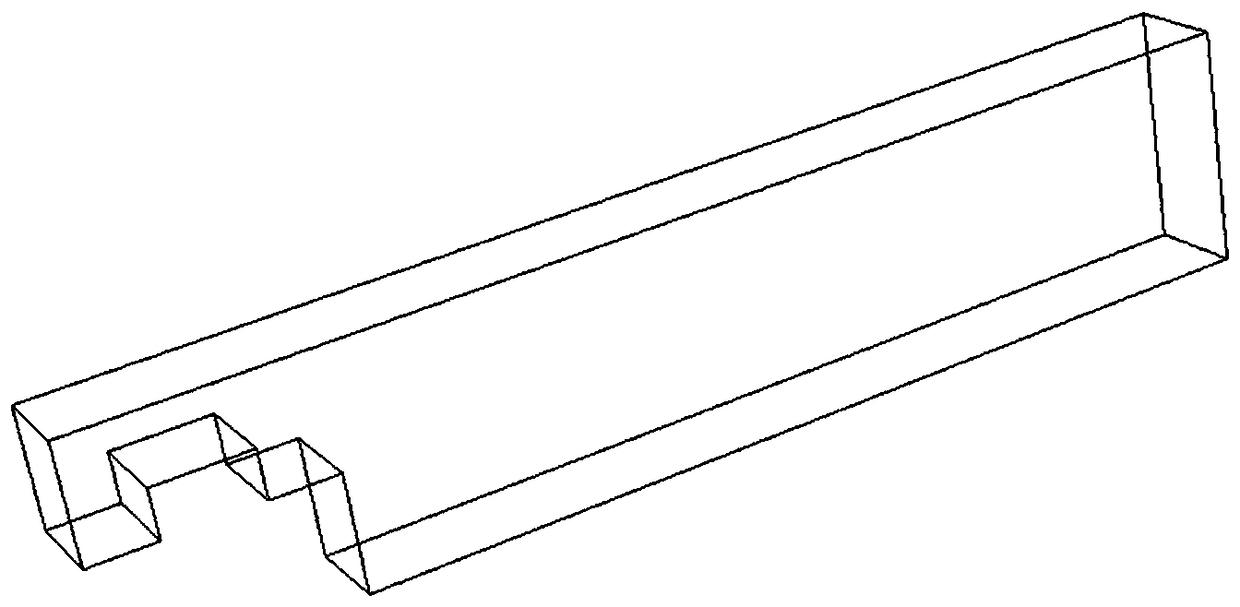

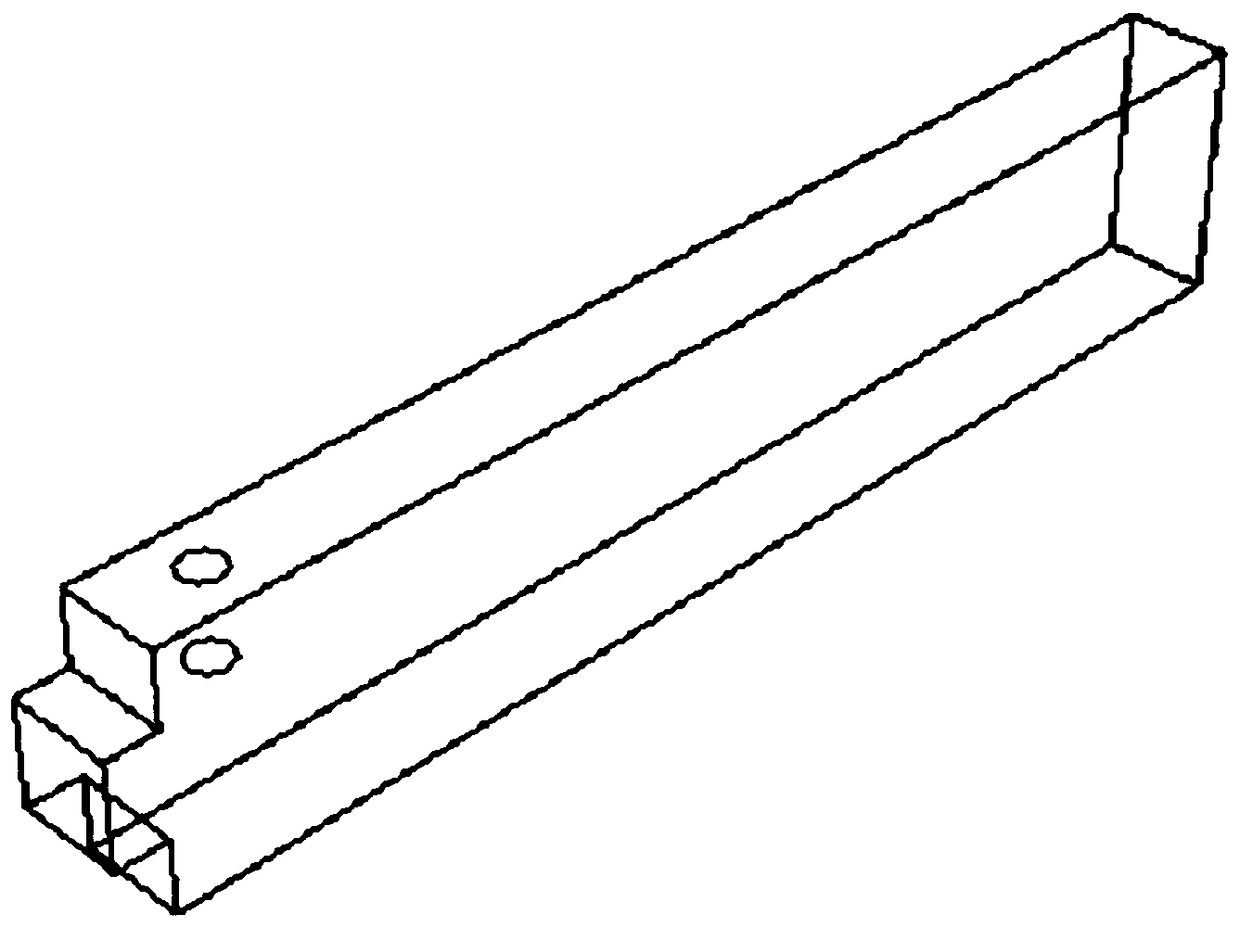

[0044] like figure 1 , 2 The schematic diagrams of the first beam and the second beam are respectively. One end of the two beams extends outward to form a tenon, and the tenons of the two beams have a symmetrical structure, so that after the butt joint, a middle width direction can be formed for installation. The tongue and groove of the stringer. image 3 It is a schematic diagram of the longitudinal beam structure. The round hole in the figure indicates the reserved tenon groove on the longitudinal beam. The tenon groove is located next to the tenon and will not be inserted into the tenon groove of the beam, so that the tenon of the upper column can be inserted. Figure 4 It is a bottom view of the bottom of the upper column. The four rectangles at the four corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com