Net frame integral installation device and construction method thereof

A technology of overall installation and net frame, which is applied in the direction of construction and building structure, can solve the problems of uneconomical, difficult to control safety, inconsistency, etc., and achieve the effect of easy installation and dismantling, ensuring safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

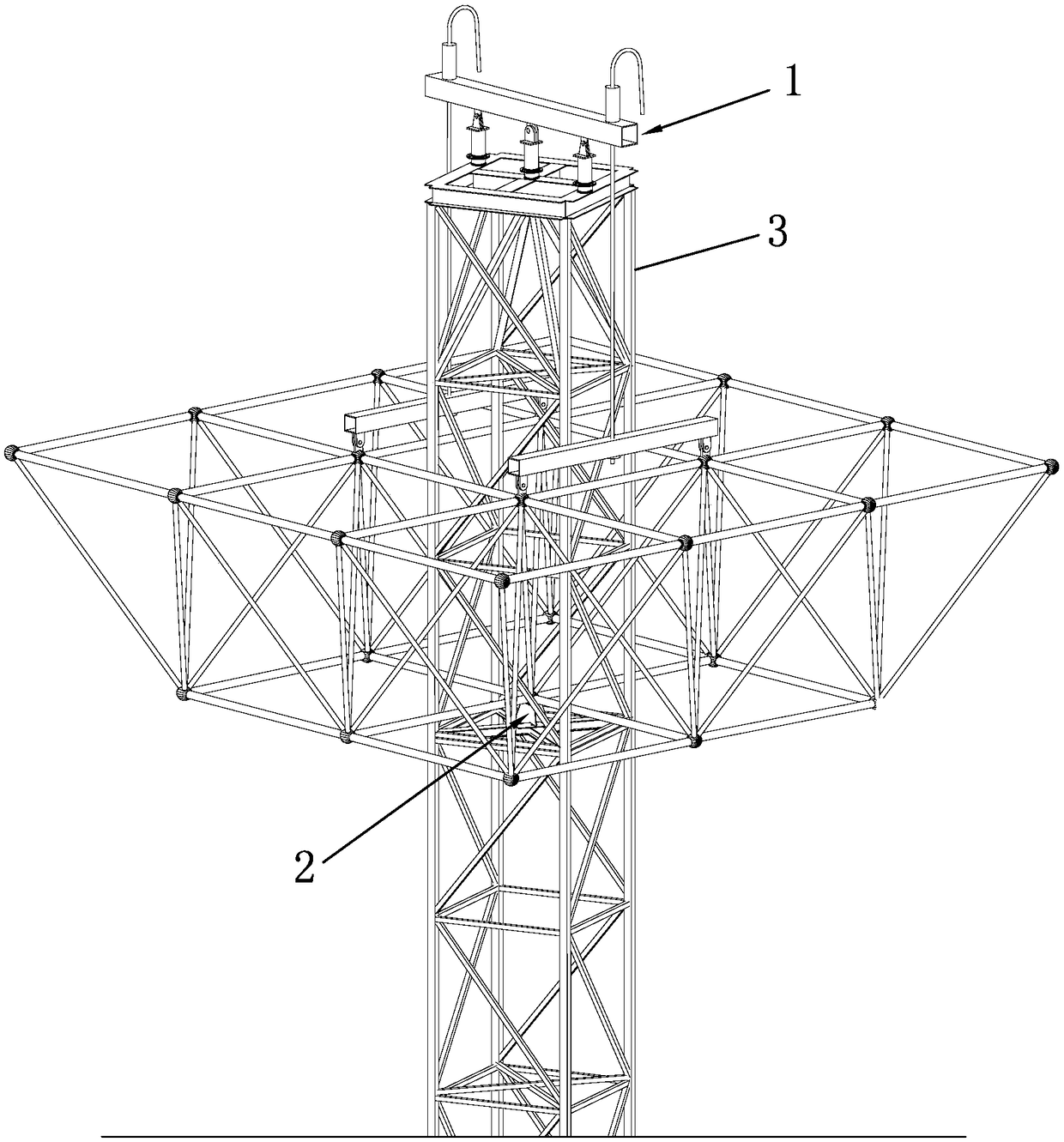

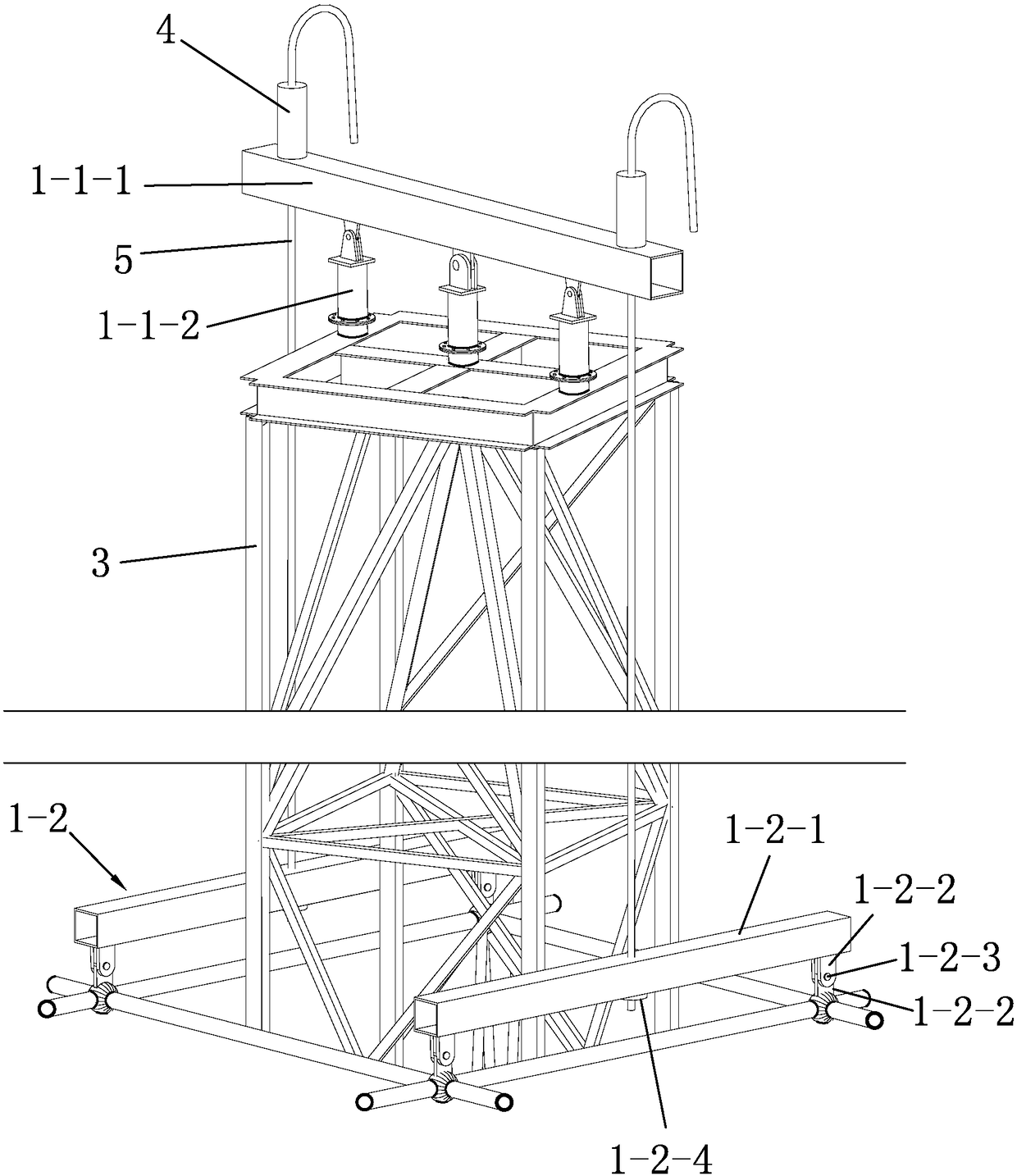

[0039] Such as Figure 1 to Figure 6 As shown, the present invention is an overall installation device for a network frame, including a self-balancing lifting device 1 , a temporary support 2 and a temporary support frame 3 for high-altitude pole repairs at network frame nodes.

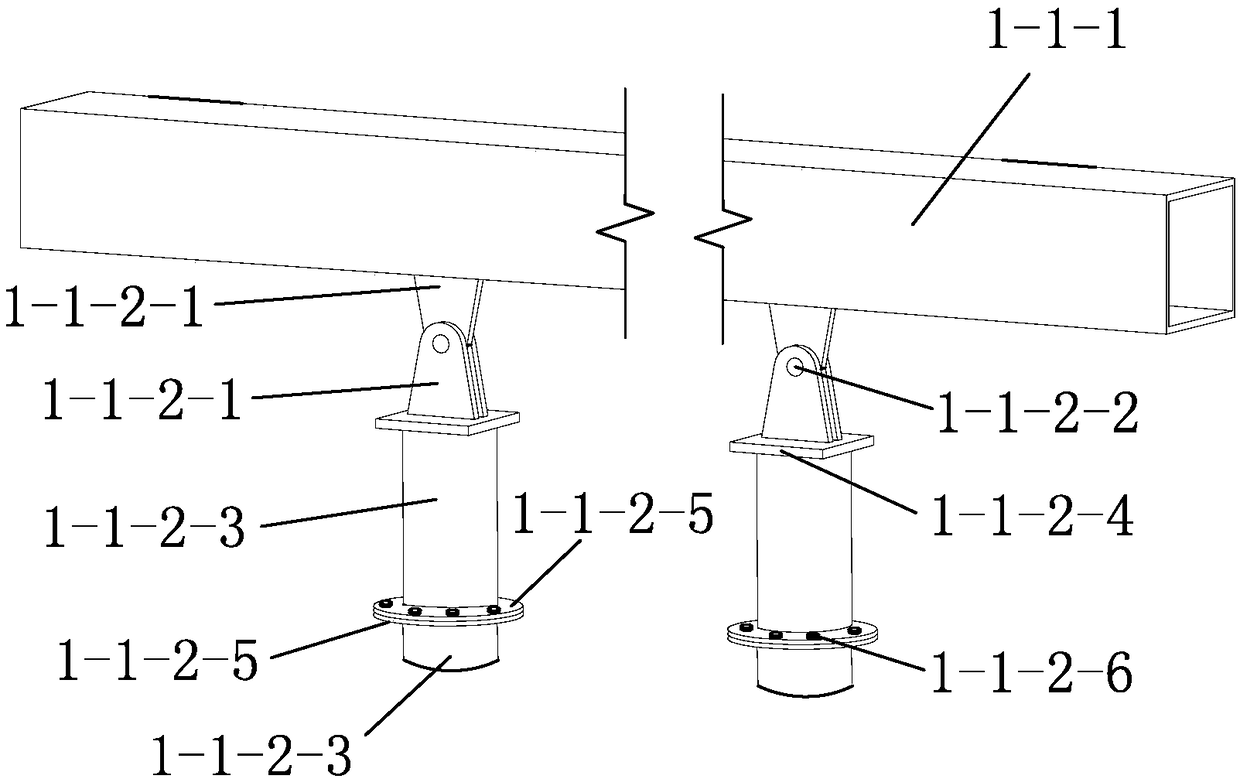

[0040] The self-balancing lifting device 1 includes a self-balancing adjustment part 1-1 and a lifting point conversion part 1-2. The self-balancing adjustment part 1-1 includes a single self-balancing adjusting shoulder pole beam 1-1-1, two temporary balancing supports 1-1-2 and a single main balancing support 1-1-3. The center position of the self-balancing adjustment pole beam 1-1-1 is on the same vertical line as the center position of the temporary support frame 3, and the main balance support 1-1-3 is connected to the center of the self-balancing adjustment pole beam 1-1-1 Between the position and the center position of the temporary support frame 3, two temporary balance supports 1-1-2 are sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com