Withdrawing type single-layer leakage-free four-way reversing valve

A four-way reversing valve and pull-out technology, which is applied to multi-way valves, valve details, valve devices, etc., can solve the problems of high cost, inconvenient maintenance, large volume, etc., and achieve the reduction of cost and weight, and a simple structure. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

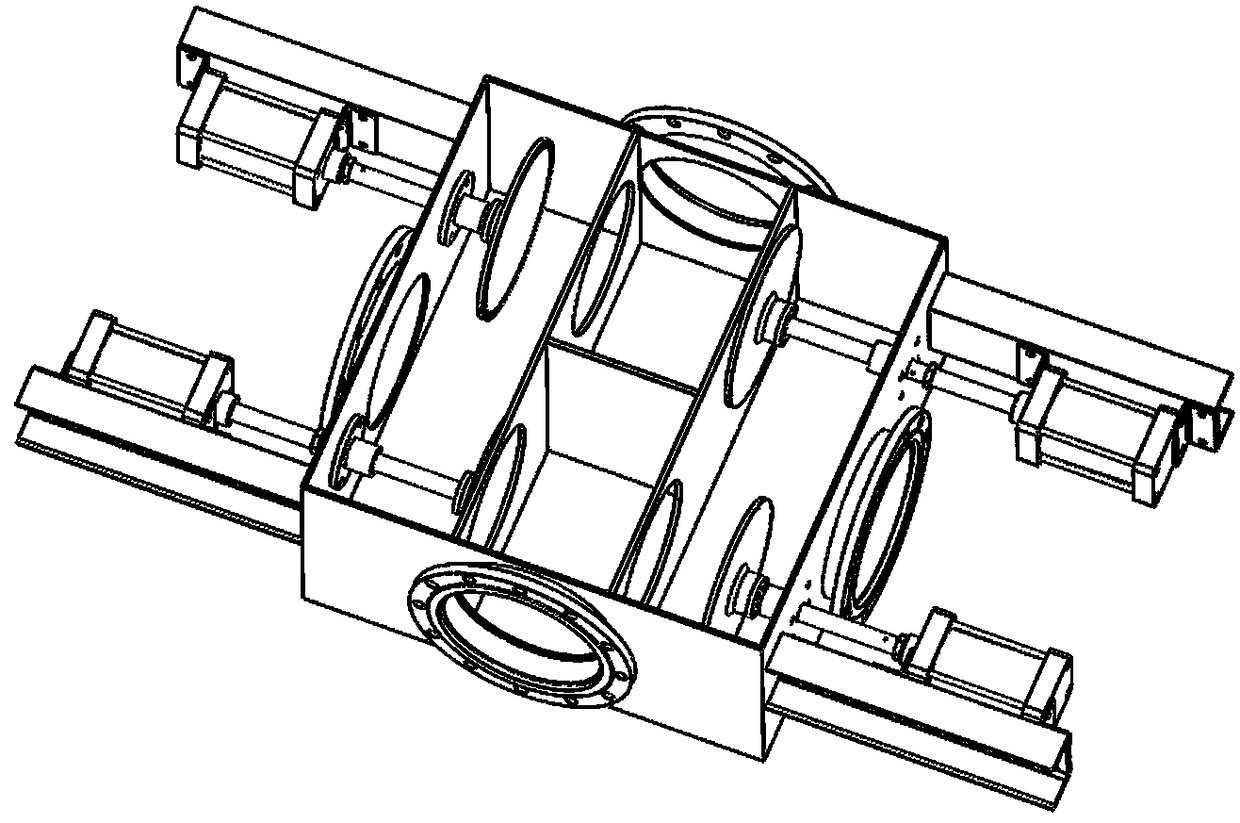

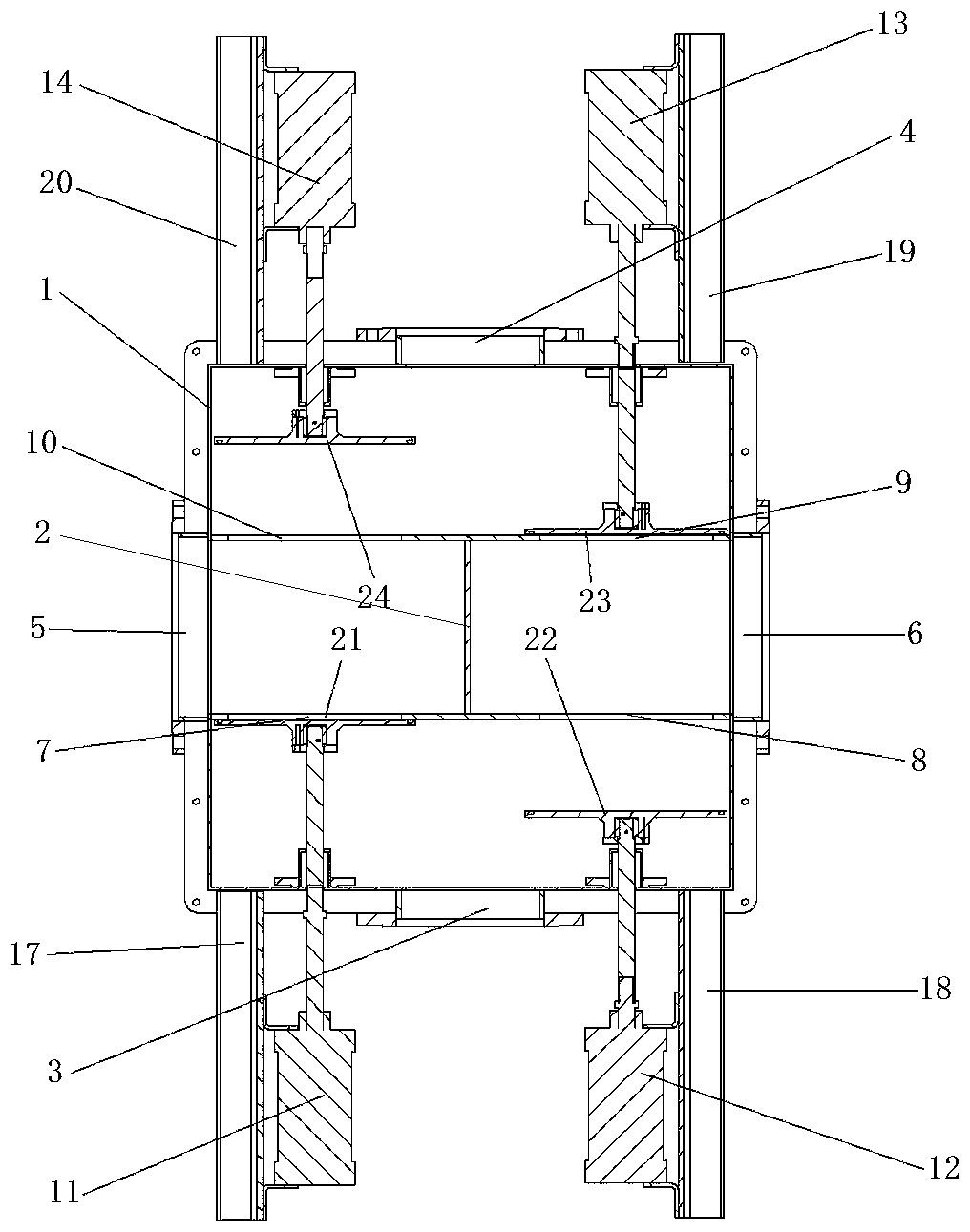

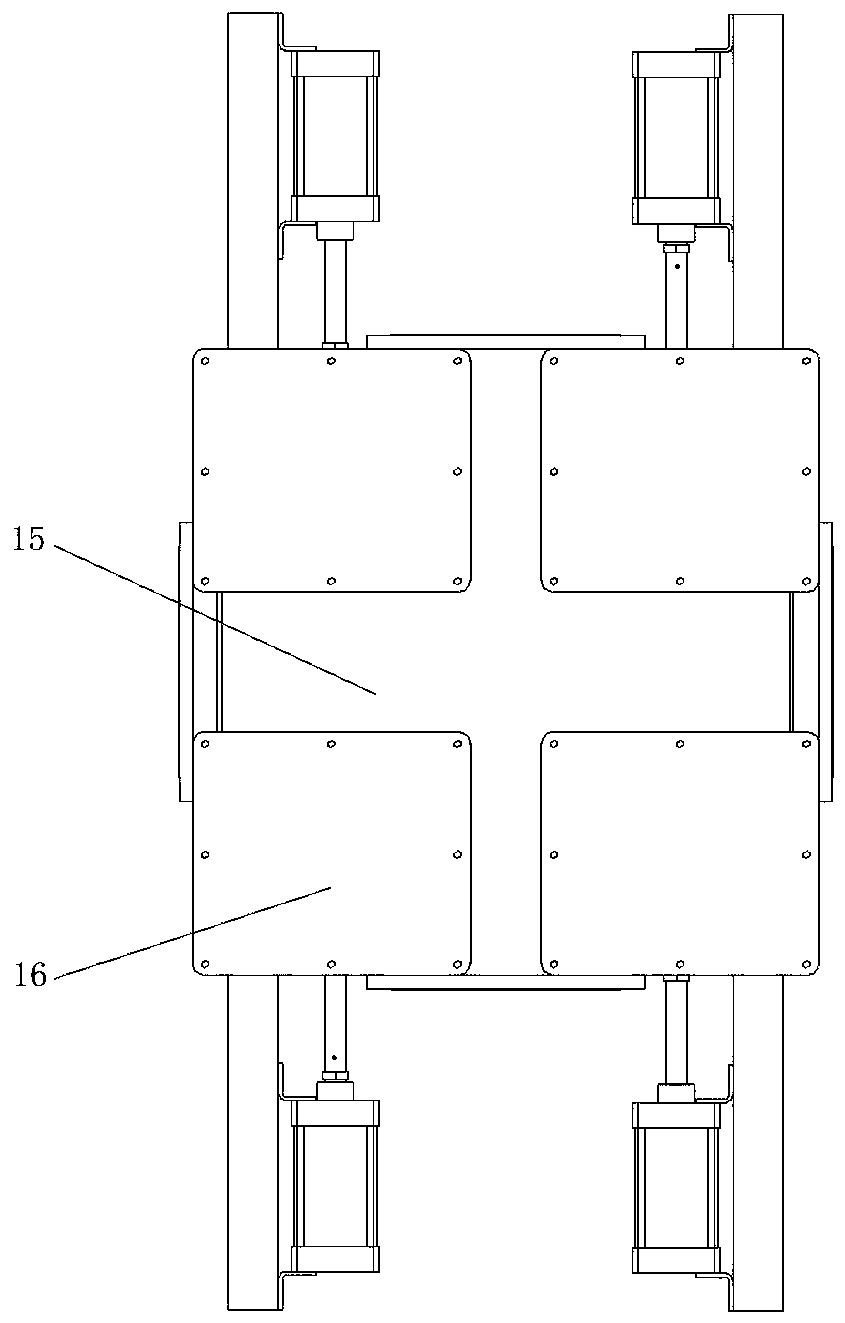

[0022] Embodiment 1, the present invention includes a valve body, an H-shaped baffle, a cover plate and a cylinder. The inside of the valve body is hollow, and the upper opening is sealed with the cover plate. The H-shaped baffle is placed inside the valve body. It is divided into 4 cavities, and a port is provided around the valve body to connect the 4 cavities with the outside respectively. There are 2 through holes on both sides of the H-shaped partition, and each through hole is equipped with A cylinder, the piston rod end of the cylinder is provided with a valve plug to cooperate with the through hole. refer to Figure 1 to Figure 5 .

Embodiment 2

[0023] Embodiment 2, a cylinder support is provided outside the valve body, the cylinder block is fixed on the cylinder support, and the piston rod passes through the side plate of the valve body so that the valve plug faces the through hole. refer to Figure 1 to Figure 5 , all the other are with embodiment 1.

Embodiment 3

[0024] Embodiment 3, the surface of the plug body of the valve plug has a slope-shaped structure, which can realize sealing by cooperating with the through hole. refer to Figure 1 to Figure 3 , and the rest are the same as the above-mentioned embodiment. refer to Figure 1 to Figure 5 , all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com