Brillouin optical fiber sensing system strain calibrating device and method

A technology of optical fiber sensing system and calibration device, which is applied in the direction of adopting optical devices, measuring devices, instruments, etc., can solve the problems affecting the demodulation accuracy of strain variables, etc., and achieve small damage to optical fibers, high detection efficiency, and simple and easy-to-operate detection methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

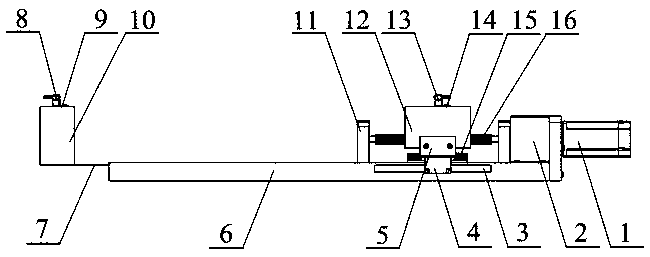

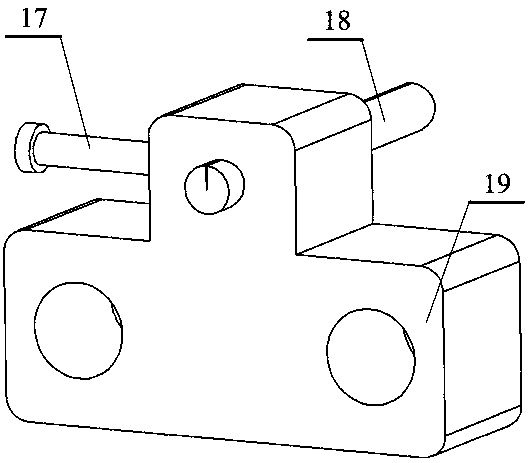

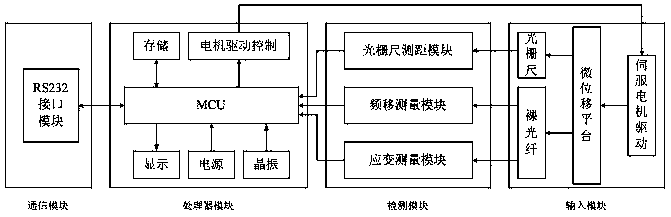

[0019] Such as figure 1 with 2 As shown, the fiber holders 8, 13 are respectively placed on the fixture table 10 and the moving slider 12 through the fiber holder fixing parts 9, 14, and are used to fix the bare fiber, so that the bare fiber to be tested is under a certain pre-tension state, the initial length l of the bare optical fiber to be tested is equal to the length between the ends of the fixed rods of the two optical fiber holders. The fixture table 10 is fixed on the movable base 7, and the distance between the fixture table 10 and the fixed base 6 can be changed by moving the base 7 to meet the requirements of measuring the strain of single-mode bare optical fibers with different lengths. The height of the upper surface of the fixture table 10 and the movable slider 12 is consistent And always fixed, the servo motor 1 and the reducer 2 are fixed on the fixed ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com