Micro photoacoustic microscopic imaging head, production method and system consisting of micro photoacoustic microscopic imaging head

A technology of photoacoustic microscopy and imaging head, which is applied in the direction of material analysis, sensor and diagnosis through optical means, which can solve the problems of low resolution of micro imaging head, short working distance, large size of imaging head, etc., so as to save production The process and the use process are simple, and the effect of easy alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

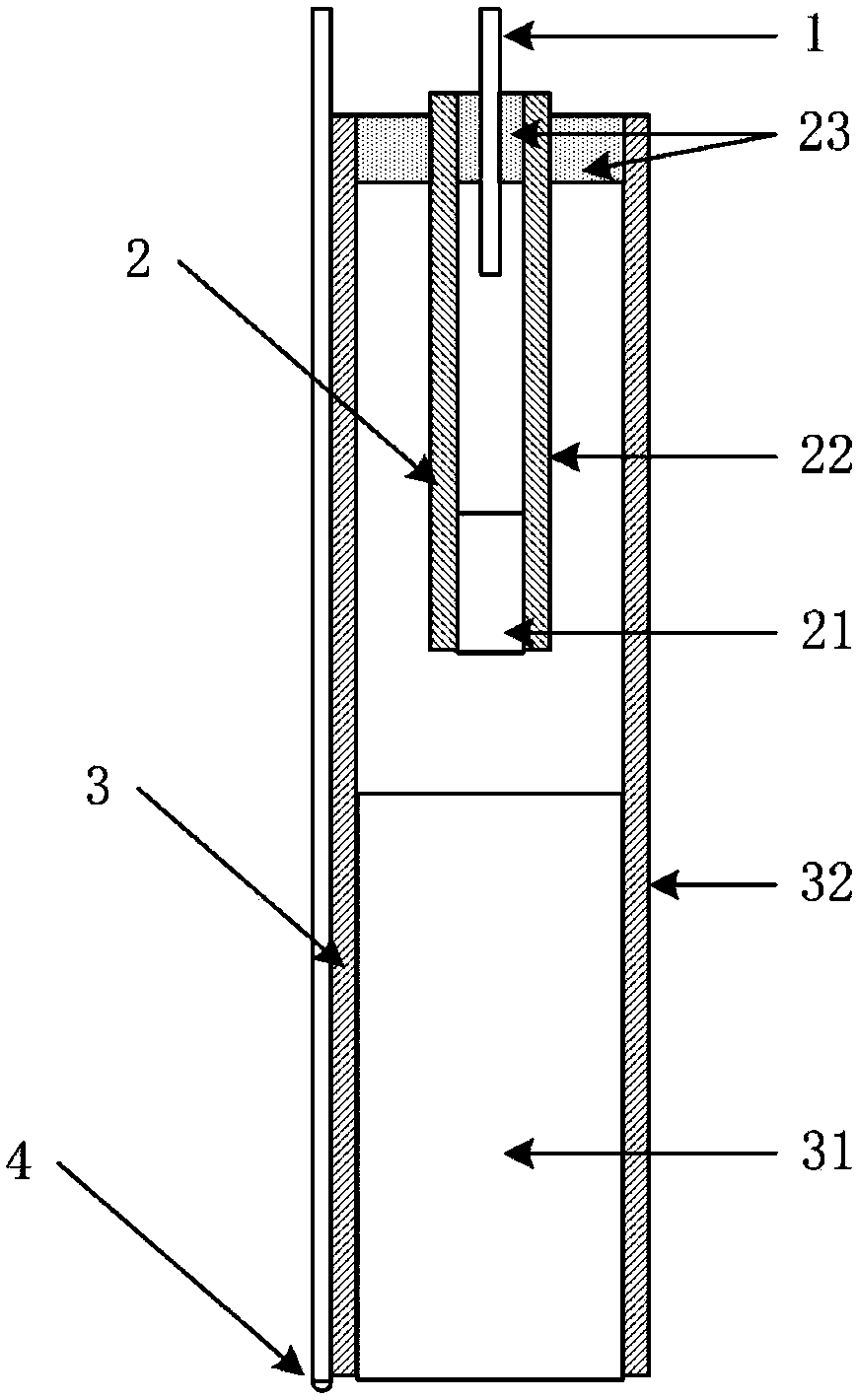

[0039] refer to figure 1 As shown, the miniature photoacoustic microscopic imaging head of the present invention includes: a single-mode optical fiber 1, a first focusing unit 2, a second focusing unit 3 and an optical fiber ultrasonic probe 4;

[0040] The first focusing unit 2 includes a first gradient index lens 21 and a glass tube 22, the first gradient index lens 21 is arranged inside one end of the glass tube 22, and the other end of the glass tube 22 is penetrated with a single-mode optical fiber 1, single The outgoing light of the mode fiber 1 corresponds to the central position of the external target (not shown in the figure) after being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com